CONSOLIDATION OF POROUS PAINT IN A VAPOR-SATURATED ATMOSPHEREERIC F. HANSEN, ROSA LOWINGER, & EILEEN SADOFF

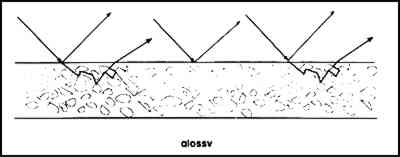

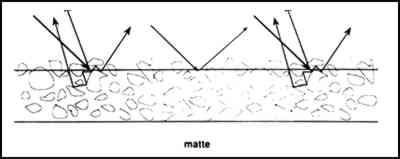

2 MATTE PAINT: SURFACE ROUGHNESS AND PIGMENT VOLUME CONCENTRATIONThe paint industry describes the concentration of vehicle and pigment in a coating based on the volume percent instead of the weight percent, because many of the properties of coatings vary according to the ratio of the pigment volume to the vehicle volume, not with the ratio of the pigment mass to the vehicle mass. An important consideration is the critical pigment volume concentration (CPVC). Above the CPVC void spaces are present. Below the CPVC the pigment particles are entirely surrounded by binder. Abrupt changes in many paint properties tend to occur at the CPVC (Patton 1979). In addition to becoming lighter in color with increasing void space, tensile properties decrease and porosity increases as the pigment volume concentration increases above the CPVC. The general reasons why paint becomes lighter as the pigment volume concentration rises above the CPVC are illustrated in figures 1–3. A film below the CPVC has an excess of resin and may exhibit a smooth surface that specularly reflects light (fig. 1). This light is perceived as gloss. Above the CPVC there is less vehicle present, and, if

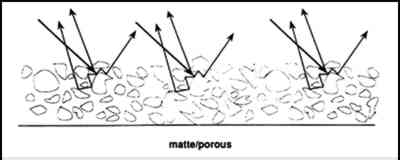

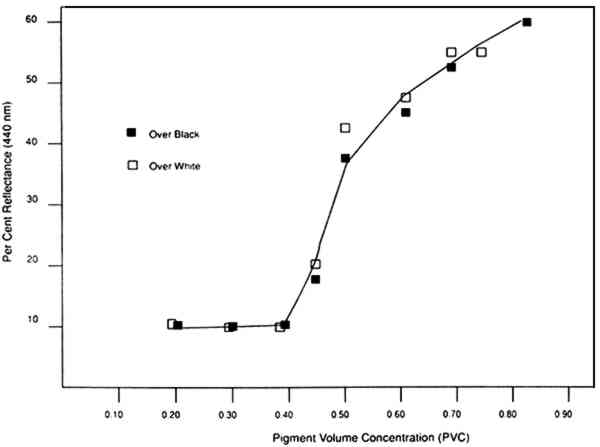

When the volume of pigment is increased sufficiently, scattering also increases due to the greater volume of air/pigment interfaces (fig. 3). This increased amount of scattered, or diffuse, light is further additively mixed as white. Feller and Kunz (1981) documented the increase in surface reflectance at 440 nm for ultramarine blue paint formulated at various PVCs (fig. 4). This is the wavelength at which the minimum reflectance will occur when the paint is saturated with vehicle or consolidant. Simply put, with increased void space (and therefore greater scattering at the air/pigment interface) the amount of reflected, diffusely scattered light increases, resulting in a light color. To avoid darkening of porous, matte paint by the addition of a consolidant, filling of void spaces and smoothing of the surface must be minimized.

|