EFFECTS OF AQUEOUS LIGHT BLEACHING ON THE SUBSEQUENT AGING OF PAPERTERRY TROSPER SCHAEFFER, MARY T. BAKER, VICTORIA BLYTH-HILL, & DIANNE VAN DER REYDEN

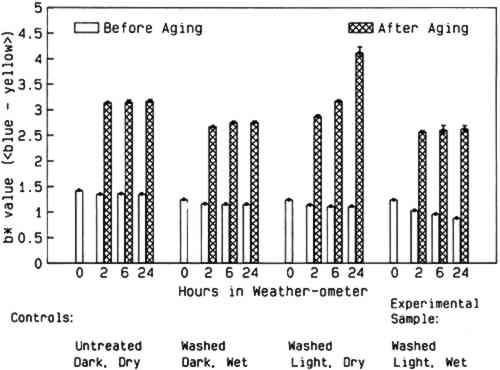

3 RESULTS3.1 WHATMAN 1 (UNSIZED CONTROL PAPER)3.1.1 Morphological and chemical characterizationThe thickness of W1 paper was not significantly changed by washing, by aqueous light bleaching, or by incubation under any of the other conditions to which it was subjected. Some treated papers that had been used for measurement of tensile properties were also examined 3.1.2 Surface pHThe pH of the untreated W1 control paper was 6.9 � 0.1, and that of the washed control paper was pH 6.5 � 0.1. The surface pH of the W1 papers was significantly decreased by Weather-ometer treatment, typically by 0.3 to 0.7 units. The specimens most severely affected were those exposed to light while dry. The pH of the immersion solutions fell, as expected. All those that had remained in the dark fell to 6.7 � 0.1; the immersion solutions that had been exposed to light had a pH of 6.3 � 0.2. Humid oven aging lowered the surface pH of all specimens significantly. Least affected were the papers that had not been washed before Weather-ometer treatments. Their surface pH following aging was in the range 5.5–5.7. In contrast, the surface pH's of the washed W1 papers were all in the range 4.7–5.1 after exposures in the Weather-ometer and artificial aging, regardless of the particular conditions to which they were exposed. The papers exposed to light appeared systematically to have pH's at the low end of this range. 3.1.3 ColorimetryThe colorimetry data for all W1 papers are presented in table 1. The untreated W1 filter paper did not appear discolored to the eye. Washing this paper did not have a significant effect on its appearance. Brightness and green-red color values were unchanged, and only a slight decrease in b∗ occurred (decrease in yellow chromophores) (fig. 2). Weather-ometer exposures of washed specimens caused further slight decrease in b∗, with the largest changes occurring in the aqueously light-bleached samples. The extent of this change appears to have been correlated to time of aqueous light bleaching.

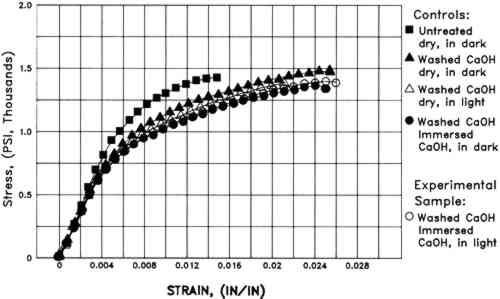

Humid oven aging caused a slight darkening of all the W1 papers (lower L∗). Changes in the aqueously light bleached samples are not distinguishable from those in washed controls that were immersed in the dark in the Weather-ometer (table 1). However, exposure of the W1 paper to light while dry resulted in significantly more discoloration upon subsequent humid oven aging (fig. 2). Increases in both red and yellow absorption (increases in a∗ and b∗) were directly related to time of dry light exposure in the Weather-ometer (table 1). 3.1.4 Tensile MeasurementsWashing the unsized W1 paper caused a significant increase in maximum strain (1.9 � 0.2% vs. 2.5 � 0.2%) but no statistically significant change in stiffness or ultimate stress to break. Immersion and/or exposure of W1 paper to light in the Weather-ometer caused no statistically significant changes in stress to break (table 2). There were no obvious systematic changes in brittleness due to Weather-ometer exposures. The averaged data (n = 3) for each of the papers exposed for 2 hours to each of the different incubation conditions are shown in figure 3. Aside from the obvious increase in maximum strain of all the washed papers, the tensile characteristics of the specimens can be seen to be very similar despite the disparate exposure conditions they endured.

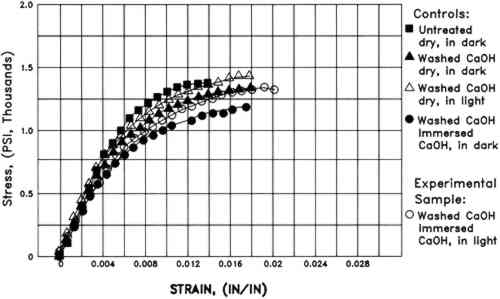

Artificial aging caused marked embrittlement but no significant changes in stress to break of the washed paper specimens (fig 4). In addition

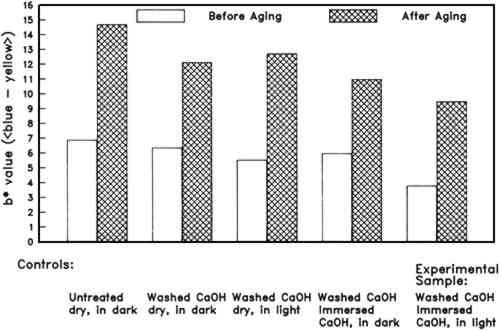

3.2 WHATMAN 1956 (ALUM- AND GELATIN-SIZED ARTISTS' PAPER)3.2.1 Morphological and chemical characterizationAll papers on which spot tests were performed gave positive results for both the alum and the ninhydrin protein test. However, W56 paper that had been immersed in the Weather-ometer for 24 hours responded to the ninhydrin test with blurred spots and slower color development, which might be indicative of lesser amounts of protein present. The characteristic protein bands were still present in an FTIR reflectance spectrum of a paper that had been immersed while in the Weather-ometer. Loss of some protein from the W56 paper into the immersion solution was confirmed by Lowry assays of two W56 immersion solutions for protein, using a gelatin protein standard. Both a light and a dark immersion solution had ca 0.25–0.3 mg protein per ml of solution. This result corresponds to a loss of 15–18 mg of gelatin from the paper specimen, or about 6–8% of the weight of the paper before incubation in the Weather-ometer. Very low levels of aluminum were also detectable by EDX in the papers after they had been in the Weather-ometer, whether or not they had been immersed. This result is consistent with the positive alum spot tests obtained on all the differently treated papers that were tested. The thickness of the W56 paper increased by approximately 15% after washing, a result that may be due to swelling of the paper as a consequence of removal of size. Immersion during incubation in the Weather-ometer did not cause any additional change in the thickness of W56 papers beyond that observed after the washing step. Artificial aging also had a negligible effect on paper thickness. 3.2.2 Surface pHSurface pH of the untreated W56 paper was 4.7 � 0.1. The washing procedure raised the surface pH to 5.3 � 0.1. The surface pH of the papers after Weather-ometer treatments did not significantly change. The pH of the immersion solutions fell about 1 unit further than the corresponding W1 immersion solutions did. The extent of decrease was somewhat greater for the aqueous light-bleached samples than for those kept in the dark. It appeared to depend slightly on the length of time in the Weather-ometer. The surface pH of all washed, aged W56 papers was in the range 4.5–4.7. The value appeared to be independent of type or length of Weather-ometer exposure. The surface pH of all the W56 controls aged without washing or without Weather-ometer exposure was decreased to 4.5 by humid oven aging. 3.2.3 ColorimetryThe CIE L∗a∗b∗ values for all the W56 papers are summarized in table 3. The W56 paper appeared cream colored when received. It was lightened slightly by washing in dilute Ca(OH)2, losing some red- and to a lesser extent, yellow-absorbing material. Immersion and light exposure in the Weather-ometer both caused additional color loss and lightening of the papers. Aqueous light bleaching resulted in a synergistic effect, seen most markedly in the time-dependent decrease in b∗. For example, immersion in the dark or dry light exposure for 2 hours each caused about a 15% decrease in b∗,

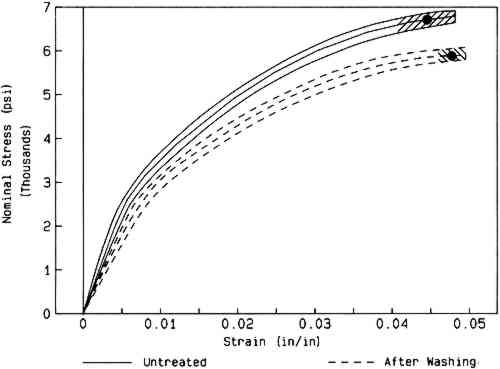

Marked color reversion occurred in all W56 papers upon humid oven aging (table 3). The extent of darkening and discoloration depended strongly on the conditions of Weather-ometer incubation. After artificial aging, only the papers that had been immersed remained significantly lighter than the washed control. The samples that were aqueously light bleached for 24 hours were the least discolored by aging. Again, the changes in the amount of yellow-absorbing material were the most dramatic (fig. 5). Of all the washed, Weather-ometer–incubated W56 papers, those that were exposed to the light while dry showed the greatest color reversion. In addition, these were the only papers in which a statistically significant difference between recto and verso color was observed for b∗, and they also had markedly more red-absorbing material. They did not, however, reach the extent of discoloration that the unwashed, untreated W56 paper did upon humid oven aging (table 3). 3.2.4 Tensile measurementsThe tensile behavior of the W56 paper as received (untreated) and after washing is shown in figure 6. The washed paper appears to display a slight decrease in stress to break, compared to the unwashed controls. However, the ca. 15% increase in thickness of the W56 paper after the washing step (see above) would contribute substantially to the apparent decrease in nominal stress, which is inversely proportional to the cross-sectional area (= width � thickness) of the paper strip.

The W56 controls that were exposed to dry Weather-ometer conditions did not display significant changes in their tensile properties, |