OBSERVATIONS ON DEVELOPMENTS IN THE TREATMENT OF WORKS ON PAPERT. K. McCLINTOCK

3 GRADATIONS OF TREATMENTThe desire to minimize risk has led to an interest in how treatments can be gradated, particularly with solvents and moisture. Water is probably the single most effective tool available to paper conservators. It is critical for cleaning, reducing planar distortions, reversing many adhesives, restoring suppleness to paper, and repairing or reinforcing a sheet. Full immersion in water dramatically illustrates both the extent of treatment that may be possible and the necessity Because GoreTex allows the unidirectional passage of water vapor and has a very smooth surface, it makes possible the extremely controlled introduction of moisture even to objects with a fragile or loaded surface. Humidification can take place by dampening the fibrous reverse side, under damp blotters or within a dome where vapor has been introduced with an ultrasonic humidifier, generally in preparation for flattening, removing mounts, or conditioning an object before work on a suction table. If washing on the suction table is the objective, the passage of moisture through the GoreTex may still be desirable to minimize oversaturation. GoreTex is also effective for introducing solvents by spray or by saturated blotters. The Lascaux humidity chamber (fig. 1) further refines the introduction of moisture to a controlled level of humidity over prolonged periods.

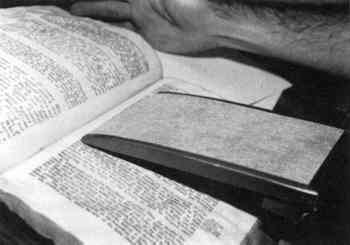

Small suction discs and plates capable of great pressure are now widespread and tailored to specific applications (fig. 2). They have largely supplanted the use of full-scale suction tables for local moisture treatment, and they complement the use of mineral poultices for local solvent treatment. Even when used with moisture in a form as discrete as vapor, worthwhile changes can be effected. Concerns that artifacts on suction tables serve, in effect, as filters in a less than pure environment have been addressed by the incorporation into consoles of air intake filters and, in the most comprehensive development, of functioning within prefiltered clean rooms.

Still shy of full immersion in water baths are the numerous refinements of float washing systems to promote additional control while drawing out water-soluble discoloration or degradation products. Blotters set on an incline saturated with running water channeled underneath act as an effective washing bed. Another system involves supporting the humidified object on a matched pair of screens that face each other, allowing the water to be raised to a level precise enough to achieve saturation of the object, and then pulling the screens apart regularly to draw the discolored solution out of the sheet. A more clear understanding of the length of exposure to water that is necessary to achieve cleanliness or to remove agents introduced allows The research directed at the wetting of sheets has also promoted interest in the related subject of flattening. Uniformity of response is the objective whereby, even after limited humidification at one extreme or full saturation at the other, the edges and interior of the sheet dry at the same rate. One of the more imaginative approaches has been the use of acid-free corrugated sheets with mat board adhered to both sides. Objects are interleaved in a stack under pressure and with air directed through the channels to accelerate evaporation of the moisture wicked through the boards. |