DETERIORATION OF SURFACES EXPOSED TO ENVIRONMENTAL CHANGESGUSTAV A. BERGER, & WILLIAM H. RUSSELL

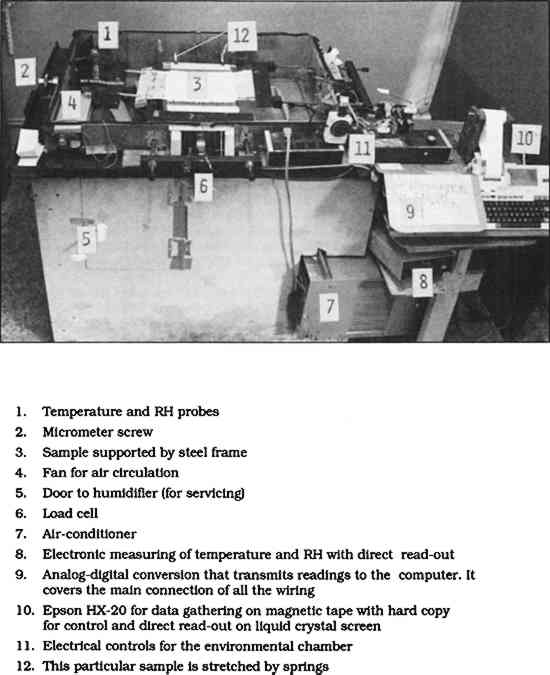

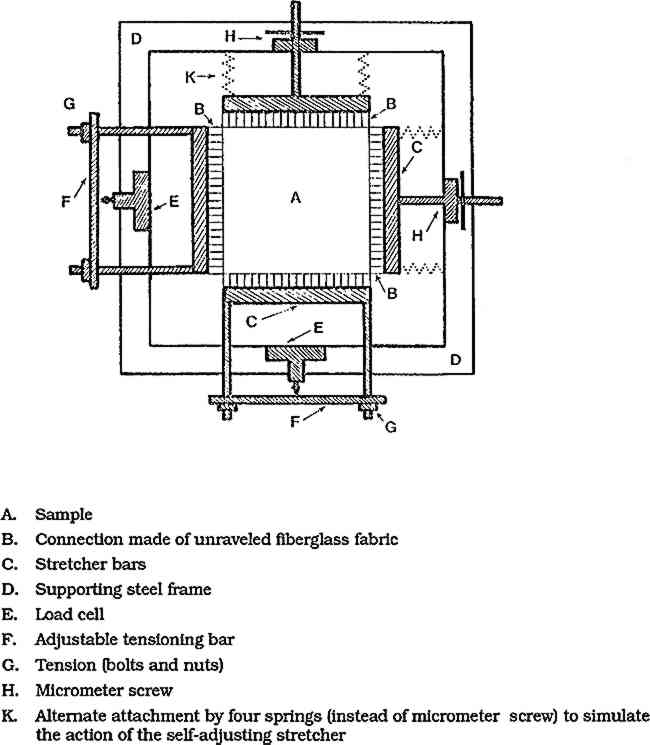

13 TEST EQUIPMENTA BIAXIAL stress tester for stretched canvas shown in figures 20 and 21 was built and perfected (Russell and Berger 1986; Berger and Russell 1988). The test arrangement, whereby the samples are subjected to controlled environmental changes, closely resemble the conditions to which canvas paintings are actually exposed. Canvas samples, 25 � 25 cm in size (A) are mounted within a rigid steel frame (D), which restrains the deformation of the canvas during testing. Threaded rods (G) permit adjustments of the tension in the canvas. The stress in the warp and weft directions is measured by separate load cells (E). Thus, it is possible to observe the restrained canvas sample and measure changes in tension (stress) as they occur in actual paintings. To ensure a uniform stress distribution, the edges of the sample must be supported continuously. Each direction also must be able to respond independently. These conditions are met with fiberglass fabric (B) whose

∗ Reprinted from Studies in Conservation 33(4):189 with the permission of the International Institute for Conservation of Historic and Artistic Works, 6 Buckingham Street, London, England WC2N 6BA. The testing frame is enclosed in an environmental chamber that makes it possible to subject the sample to changes of temperature (between 0�C and 50�C) and RH (from ca. 5% to 100%). The arrangement proved extremely sensitive. Changes of 0.1�C or less than 0.1% RH that could not be recorded on the measuring probes often caused measurable changes in tension. As testing continued, it became clear that the previous history of the environment had a considerable influence on the reactions of the sample. The stress tester was therefore automated to collect readings for extended periods without interruption. In 1984, Gordon Minns, President, Stable Technologies, Suffield, Connecticut, wrote a special program for data gathering. His program records readings every 15 seconds on a liquid crystal screen. They are printed on paper in selected intervals and recorded on magnetic tape. Once a week the data are transferred to disk, but during vacations the computer can work for months without supervision. As we became more familiar with computers and measuring instruments, we began to use feedback from the environmental chamber to produce recurring patterns of environmental changes that could be compared with each other. This system of controlled cycling is presently our main research tool in conjunction with biaxial stress/strain measurements of canvas, for which this experimental set-up seems very well adapted. ACKNOWLEDGEMENTSTHE AUTHORS wish to thank the Samuel H. Kress Foundation and its president, Dr. Marilyn Perry, for continuous financial and moral support of this research project. Grateful acknowledgment goes to the Georgia Institute of Technology College of Architecture for its continuous help. To the Brown Foundation, Inc., and the numerous other dedicated supporters, gratitude is expressed. The contents of this paper were presented at the 16th Annual Meeting of the American Institute for Conservation in 1988. |