A COMPARISON OF SELECTED UV FILTERING MATERIALS FOR THE REDUCTION OF FADINGPatricia Cox Crews

2 EXPERIMENTAL PROCEDURE2.1 FabricTWO WOOL FABRICS, one dyed with synthetic blue dyes and one undyed, were purchased for use in the study. The plain weave, worsted wool fabric dyed with synthetic blue dyes was purchased from AATCC (Research Triangle Park, N. C.) It is called Blue Wool Lightfastness Standard L2. Blue Wool Lightfastness Standards are prepared by blending varying proportions of wool dyed with a very fugitive dyestuff, Erio Chrome Azurole B (C.I. 43830) and wool dyed with a fast dyestuff, Indigosol Blue AGG (C.I 73801) so that each higher numbered standard is approximately twice as colorfast as the preceding standard.2 Blue Wool Lightfastness Standards L2 and L4 have been used by several researchers in evaluating the effectiveness of UV filters.8,10 The undyed fabric selected for dyeing with natural dyes was a worsted wool flannel, Style 523, purchased from Testfabrics Inc. (Middlesex, N. J.). Wool samples measuring 22.7 cm � 30.5 cm were scoured individually in 0.5% AATCC neutral soap solutions (wgt./vol.) at 90�C for 30 minutes to remove impurities from manufacturing in preparation for dyeing with natural dyes. 2.2 Dyeing ProceduresScoured wool samples were dyed in stainless steel, high-temperature Launder-Ometer canisters with 12 dye/mordant combinations following 19th-century procedures.6 The natural dyes included cochineal, madder, indigo, fustic, weld, and turmeric. They represent some of the most widely used dyes for red, yellow, and blue colors in American and European textiles prior to the 20th century.1,4,5 In addition, their lightfastness properties ranged from fugitive (turmeric) to very stable (indigo). The detailed dying procedures are reported elsewhere.3 2.3 Ultraviolet Filters and Light ExposureSelected for evaluation and comparison in this study were four UV filters:

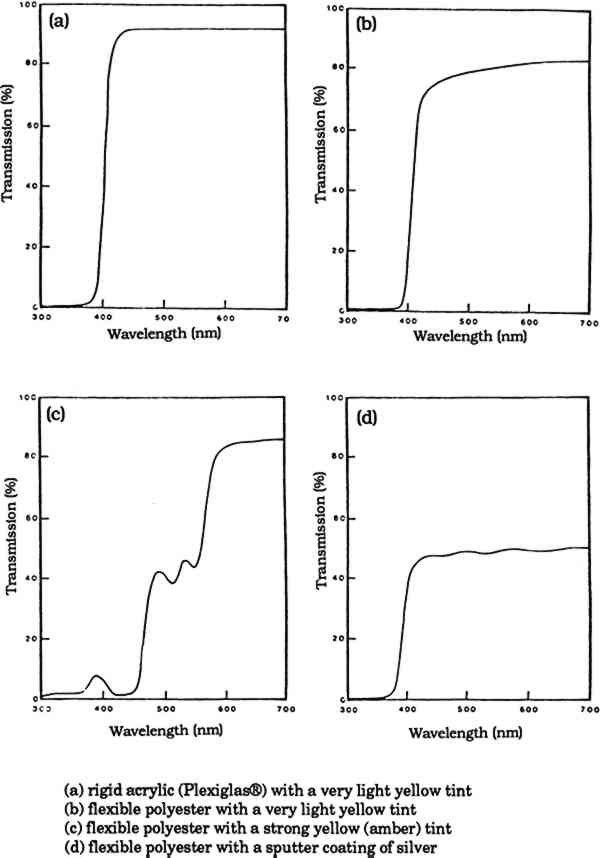

Ultraviolet-visible transmission spectra were made of each filter using a Perkin Elmer 552 UV-visible spectrophotometer. The filters were cut to fit in the specimen port. The transmission spectra of each are shown in figure 1. The rigid and flexible filters with a light yellow tint were substantially colorless transmitting almost all radiation in the visible region of the electromagnetic spectrum but absorbing almost all radiation below 380 nm. The amber filter absorbed strongly in the blue region (450 nm) of the visible spectrum and absorbed slightly less UV radiation in the 380–400 nm wavelength than did the substantially colorless filters. The grayish polyester filter with the silver reflective coating, like the almost colorless filters, absorbed almost all radiation below 380 nm, but unlike the substantially colorless materials transmitted only 50% of the visible radiation. Surprisingly, despite the measurable reduction in transmitted light shown in the spectral curves, the gray filter with the silver coating did not alter color rendition or diminish light levels to a very noticeable extent visually when used as a UV filtering sleeve on a fluorescent lamp in an exhibit case. In fact, it was difficult to distinguish between the areas lighted by lamps with the almost colorless flexible polyester filter and the silver-coated polyester filter.

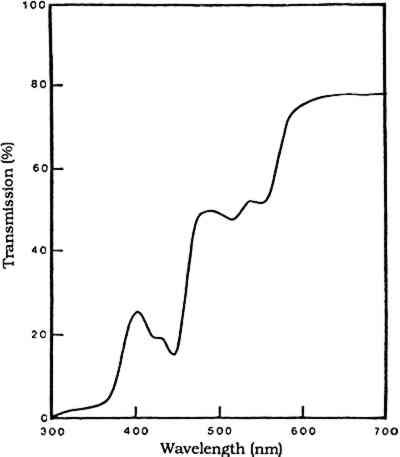

UV-visible spectra were made of the filters before and after 80, 100, and 600 AATCC fading units (AFUs) of xenon light exposure. An AATCC fading unit is the amount of exposure required to produce 1 CIELAB unit of color difference on Xenon Reference Fabric used for the calibration of water cooled xenon-arc equipment.2 Comparison of the spectra before and after 100 AFUs of xenon light exposure showed that none of the spectral curves were significantly altered by that length of exposure. These findings supported earlier work which showed that 80 AFUs of xenon light exposure did not significantly alter the spectral curves of amber and clear flexible polyester filters.3 However, 600 AFUs of light exposure significantly altered the flexible filter with the amber tint (see figure 2). The amber filter visibly lightened during exposure, as shown by the increased transmittance of visible radiation near 400 nm and 500 nm on its spectral curve. Unlike the flexible amber filter, the flexible polyester filters with the light yellow tint and the silver coating retained their effectiveness as UV filters as well as the rigid acrylic filter throughout 600 AFUs of light exposure.

The UV filters were placed directly over the dyed wool specimens when they were mounted in Atlas SL-8A Fade-Ometer test masks. Specimens were exposed to xenon light for 80 AFUs according to AATCC Test Method 16-E, Colorfastness to Light: Water-Cooled Xenon-Arc Lamp, Continuous Light in an Atlas (Chicago, Ill.) 6,500-watt xenon-arc Weather-Ometer.2 Xenon reference fabric was used to control the exposure periods. Borosilicate inner filters and soda lime outer filter glasses were used with the xenon lamp to simulate light exposure behind glass. 2.4 Instrumental Color EvaluationThe dyed specimens were evaluated before and after exposure to 80 AFUs of xenon light with a HunterLab D25-M tristimulus colorimeter using a 2.54 cm viewing aperture. Total color change that occurred during each exposure period was calculated according to the CIE 1976 L∗a∗b∗ color difference (DE) equation:

The calculated unit of color difference is abbreviated the CIELAB unit. 2.5 Statistical AnalysisOne-way analysis of variance (ANOVA) was used to measure the effect of filter on total color difference after light exposure. If ANOVA procedures showed that type of filter significantly affected total color difference, Fisher's LSD Test was used to determine which UV filter differed significantly from the others. The level of significance was set very conservatively at .01 for the analysis of variance and .05 for Fisher's LSD |