DEGRADATION IN WEIGHTED AND UNWEIGHTED HISTORIC SILKSJanet E. Miller, & Barbara M. Reagan

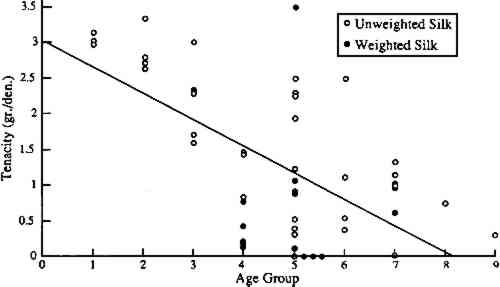

3 RESULTS3.1 Characteristics of Historic Silk FabricsTHE TYPE OF SILK (cultivated [Bombyx mori] or wild [Tussah] silk), fabric type and count, warp yarn denier and twist, condition, age group, and corresponding code for the naturally aged, historic silk fabrics are presented in table 1. Fabric counts ranged from 12 to 280 yarns per inch in the warp and from 32 to 158 yarns per inch in the filling. The mean fabric counts for the 54 fabric samples were 133 (warp) � 94 (weft). The warp yarn deniers, which were used in calculating breaking tenacity, also varied considerably and ranged from 22 gf/den. to 327 gf/den. Most of the warp yarns had little or no twist (i.e., TPI = ≤5 twist per inch). Over 50% of the historic fabrics were designated as being in good condition, whereas approximately 25% were in poor or fair condition. Table 1 Construction Characteristics, Condition, and Age of Historic Silk Fabrics A summary of the neutron activation analysis (NAA) data showing the approximate percentage by weight of the metallic elements present in the unweighted, new silk habutai (designated C-55) and the 54 historic silk samples, the total percentage of weighting elements, and the weighting classification (unweighted or weighted) are presented in table 2. Fabrics containing a total of 1% or more of metallic elements were classified as weighted, whereas those containing less than 1% were designated as unweighted. (Note that this is not the percentage of the metallic salt.) Fifteen of the 54 fabrics were considered weighted. Table 2 Metallic Elements Present in Silk Fabrics All of the historic silk fabrics and the new silk habutai contained Mn56, a daughter isotope of iron, indicating the presence of iron in amounts varying from <0.01% to 0.63%. Trace amounts (<0.01% to 0.15%) of aluminum were found in 44 samples. Barium, which has been used as both a delusterant and weighting agent, was present on 23 samples in amounts ranging from 0.01% to 1.68% in all age groups, except 2 (1960–75). Since iron and aluminum are common contaminants in water, perhaps these elements were deposited on the silks during wet processing. Na and Cl were found in all samples but were not quantified. NAA is very sensitive to both Na and Cl and can readily detect contamination from handling. Iron and aluminum were found in all age groups, including the unweighted, new silk habutai. The highest element percentages were associated with tin, which was expected since tin salts were commonly used in silk weighting. Tin was detected in 13 historic silks, and in all but two specimens the concentrations exceeded 3% of the total fabric weight. Interestingly, the samples that contained tin and chromium were in age groups 4 and 5 (1890–1939). Eleven silk fabrics in three of the four age groups between 1700 and 1939 contained potassium in amounts of 0.05% to 2.45%. Low concentrations (<0.01%) of copper were detected in six samples, all of which dated earlier than 1890; and five contained trace amounts of arsenic (<0.01% to 0.13%), with the same age group distributions as potassium. Indium, a rare earth metal not commonly used as a weighting agent, was detected in six fabrics at concentrations of <0.01%. Its presence may have been due to transformation of Sn125 to In 116M in some of the tin-weighted samples. The silk weighting literature records that lead acetate, antimony, zinc, and other metallic salts were sometimes used for weighting silk but were not of great commercial importance. Lead could not be detected using the particular irradiation times, and antimony and zinc were not detected. The research reported here only analyzed undyed silk, so lack of zinc weighted samples and low iron concentrations were not A limitation of NAA is its inability to detect lead, a known weighting agent, because irradiated lead isotopes are stable and do not become radioactive except after extended periods of radiation. Other methods of elemental analysis may be more sensitive than NAA in detecting minute amounts of some of the known weighting elements such as copper. Hence, a combination of analytical methods such as NAA, atomic absorption, and X-ray fluorescence would be needed to identify all possible weighting elements. Separate NAA tests were conducted on the warp yarns only from two badly deteriorated silk fabrics (with lengthwise splits) dating from 1910 to 1915. The filling yarns could not be analyzed because they disintegrated when raveled from the fabric. 3.2 Yarn Tenacity and ElongationThe warp yarn tenacity and elongation means for the new and historic silk fabrics within type (cultivated or wild silk), age group, and weighting group are given in table 3. The new silk habutai (age group 1) had the highest mean tenacity (3.1 gf/den.) compared to the historic silk fabrics (age groups 2–9). In general, yarn strength progressively decreased with age. However, the tenacities for the individual historic silk fabrics within age groups varied considerably, and two of the silk samples had mean tenacities exceeding that obtained for the new silk habutai. Four of the historic silk fabrics had warp yarns that were too weak to be raveled from the fabric without breaking, resulting in tenacity values of 0.0 gf/den. The amount of tin weighting in three of these fabrics was in excess of 3.0%. The fourth sample was an unweighted silk from a Spanish War banner that had had excessive light exposure. As was expected, less variability in the tenacity values was obśerved for the newer unweighted silk fabrics (i.e., age groups 1 and 2) than for the older silks. Table 3 Warp Yarn Tenacity and Elongation Means for Silk Fabric However, generalizations are limited by 1) the unequal number of samples within silk type, age group, and weighting group and 2) the variability in the strength and elongation data within age groups (especially for group 5) because of inherent differences in fiber strength and elongation, yarn construction characteristics, and previous histories (including processing, use, and cleaning, etc.). For example, too few weighted silk samples were available in age groups 1–3, 6, 8, and 9 to make comparisons between the unweighted and weighted silks or to make predictions about changes in strength of silk as a function of aging. A regression analysis was performed on the yarn tenacity means to further examine the relationship between yarn strength and age. T-tests showed that the differences in the mean yarn tenacities for the nine age groups were significant at the 0.001 level. Orthogonal trend analysis indicated a linear downward trend with increasing age. When the tenacity means of individual silk fabrics were plotted on the regression line (see figure 1) only five weighted samples had means equal to or greater than the predicted values, supporting the premise that weighting has a negative effect on strength. In addition, all of the fabrics in age group 4 (1910–39) had tenacities below the predicted value of 1.92 gf/den., indicating that the samples in this age group had greater degradation than was expected based on the regression line.

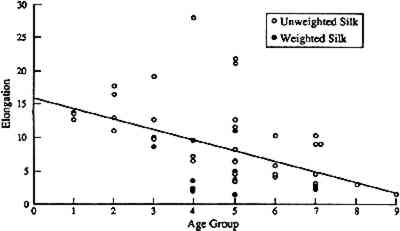

Comparison of yarn tenacity and NAA weighting results reveals an apparent disparity between strength of tin weighted and chrome weighted samples. Eleven of 13 silk samples containing combinations of tin and other metallic elements had tenacities of less than 1 gf/den. In contrast, one sample (C-37) that contained only 0.01% tin and 1.58% chromium had a tenacity of 3.5 gf/den., which is higher than the mean tenacity of the new silk. The other sample that contained chromium (2.38%) also contained 7.34% tin and 1.24% barium; however, warp yarns (C-20W) were analyzed separately and did not contain chromium. There are too few weighted samples on which to base conclusions, but possibly different mechanisms may be working with tin and chromium weighting. It is Differences also were observed in the elongation properties of the new and historic silk fabrics. The percentage elongation means associated with the nine age groups were significantly different at the 0.001 level. Results of the orthogonal trend analysis on the cultivated silk fabrics showed an inverse linear relationship between age and elongation (see figure 2), i.e., when age increased, elongation decreased. Similarly, the weighted silk fabrics exhibited less elongation than those that were unweighted. The elongation means for the unweighted silk fabrics were approximately twice as large as those recorded for the weighted silks.

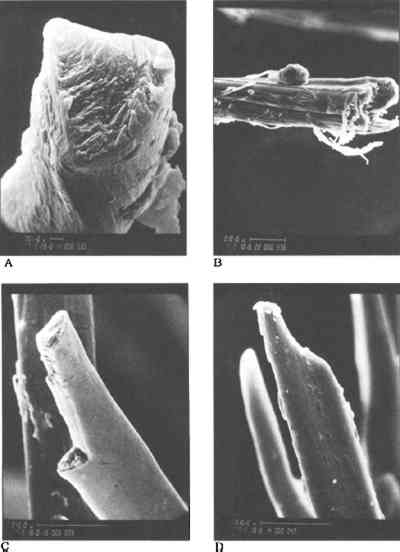

The percent elongation of warp yarn from the unweighted wild silk fabrics (25%) was substantially higher than that observed for the new and historic, cultivated silks. Lucas et al.10 reported that Tussah silk usually is weaker and more extensible than cultivated silk, because it is less crystalline and contains a larger proportion of long side-chain amino acids, which would contribute to greater extension under tension. 3.3 Dilute Solution ViscosityIntrinsic viscosity tests were performed on only the unweighted, Bombyx mori silk fabrics. The other silk samples could not be tested because the weighting agents hindered dissolution and the weighting element mass altered flow times. Wild silks would not dissolve in the saturated LiBr solution. The mean viscosity of 3.1, obtained for the new silk habutai was significantly higher than the means obtained for the historic silk fabrics in age groups 2–9 which ranged from 0.7 to 1.4 (see table 4). Within specific age groups, only one historic silk sample had a viscosity number above 2.0; the majority had viscosities of <1.0. Because of the limited number of samples within specific age groups, a greater number of samples would need to be Table 4 Intrinsic Viscosity Means for Unweighted, Cultivated Silk Fabrics 3.4 Amino Acid AnalysisThe mean weights of the 17 amino acids (per 100 g of sample) that were detected in the unweighted, cultivated and wild silk fabrics are presented in table 5. The weighted silks were not analyzed because of the possibility of contaminating the analyzer's ion exchange column. In general, few differences were observed among the age group mean weights for specific amino acids within the two silk types (cultivated or wild silk). Compared to the samples containing wild silk, however, those that contained cultivated silk had somewhat larger amounts of the simpler amino acids (glycine, alanine, serine, and valine). Lucas et al.10 reported that glycine, serine, and alanine are the major amino acids in the crystalline portion of the fibroin, whereas the bulky side-chain amino acids are found in the amorphous regions. Since cultivated silk is more crystalline than wild silk, a larger amount of the simpler amino acids would be expected. Table 5 Amino Acid Analysis of Unweighted Silk Fabrics The amount of the specific amino acids present in the silk samples varied within age group. For example, in age group 5, the amount of glycine present in the 10 samples ranged from 27.1 to 34.0 g per 100 g of sample. However, in only one of the samples within this age group was the amount of glycine less than 29.0 g. This was a rather unusual sample because the yarns were coated with a clear substance. This sample also contained a detectible amount of arginine (5.9 g) not present in the other cultivated silk samples, as well as higher proportions of proline, methionine, isoleucine, leucine, and phenylalanine. The coating may have been a protein substance, which would account for the variation in proportions of amino acids in this Because of the unequal number of samples within age groups and the variability among the samples from previous history and environmental conditions, further study is needed to determine the influence of aging on the amino acid content of silk. However, amino acid analyses provide an exciting research avenue for studying chemical changes in silks. 3.5 Optical and Scanning Electron MicroscopyOptical microscopic examination of all silk samples was done to evaluate their overall physical deterioration. Scanning electron micrographs were taken of selected samples to assess fiber fracture patterns by comparison to those characterized by Hearle6 and Bresee and Goodyear.4 Ten types of fiber fracture patterns were identified in the historic silks, some of which are shown in figure 3. Slightly less than half of the fiber fractures were combinations of two or more type of patterns, mostly granular and axial fracture types. Also widely observed were granular fractures resulting from transverse discontinuities within the fiber, �s well as axial splits with long tails related to cracks and surface flaws. Other fracture patterns observed to a lesser extent were axial angular splits, V-shaped fiber fractures, and fibrils or fibril bundles. Many of the heavily tin-weighted fabrics had broken filaments with smooth fiber ends. The great variety of fracture patterns observed among the silk samples reflected the diversity in histories and factors that contribute to silk aging.

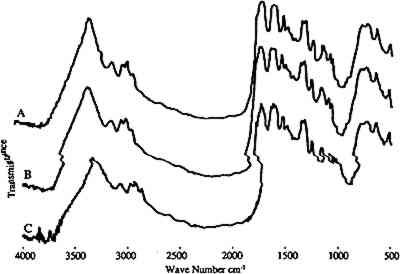

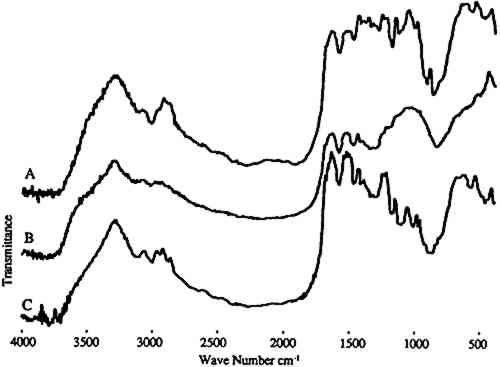

3.6 Photoacoustical Infrared SpectroscopyThe major, characteristic, infrared absorption bands or peaks as identified by Asia et al.2 were present in both the new silk habutai and in historic silk samples C-49 (200 years old) and C-22 (400 years old), as shown in figure 4. For example, the absorption band at 3300 cm−1 is attributed to N-H stretching of hydrogen bonds (i.e., −NH…O=C−). The absorption band at 1640 cm−1 is associated with C=O stretching vibrations. However, the infrared spectra of the chromium- and tin-weighted silks differed from that of the unweighted silk (figure 5). Some of the major absorption bands were rounded and/or flattened, indicating appreciable changes in chemical structure.

|