MOUNTING SYSTEMS FOR ETHNOGRAPHIC TEXTILES AND OBJECTS

Gail Sundstrom Niinimaa

9 MANNEQUINS

Mannequins are made from an Ethafoam disc system which is carved to the proper body shape suitable for each costume. This method was first developed by Colleen Wilson of the British Columbia Provincial Museum, using styrofoam and PVA adhesive. Glenbow uses the same method and different materials—Ethafoam and 3M brand Adhesive-product EC4693 (S.B-R base in aliphatic solvent).

The following steps are used to construct a mannequin:

- The inner measurements of the garment are taken, using the waistline or other suitable reference points as the centre point and working up and down at a depth corresponding to the thickness of the foam.

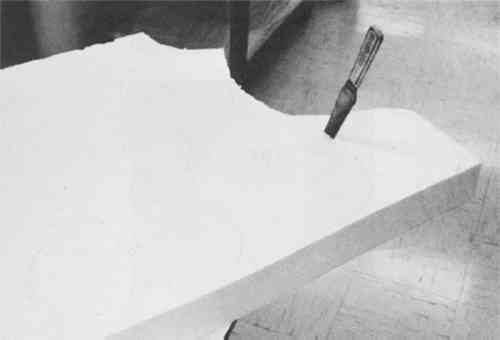

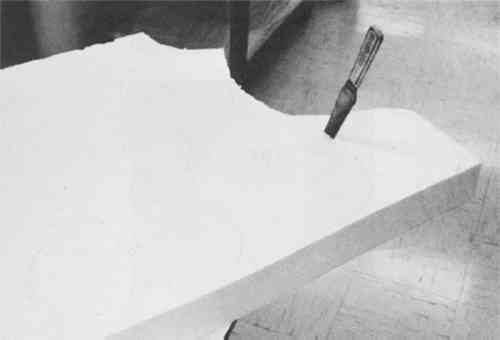

- Approximately 2 inches or 5cm are subtracted from the measurements which are then transferred to a disc-shaped oval and cut out of the foam. All garments have 2–4 inches of ease, which allows for better comfort by the wearer; this subtraction takes this into consideration. (See figure 7.)

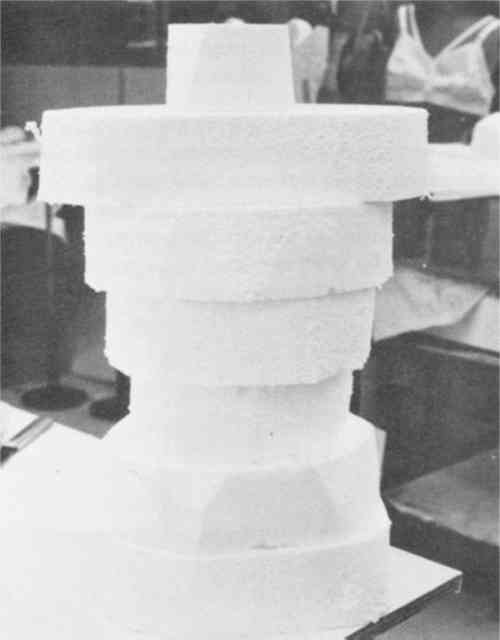

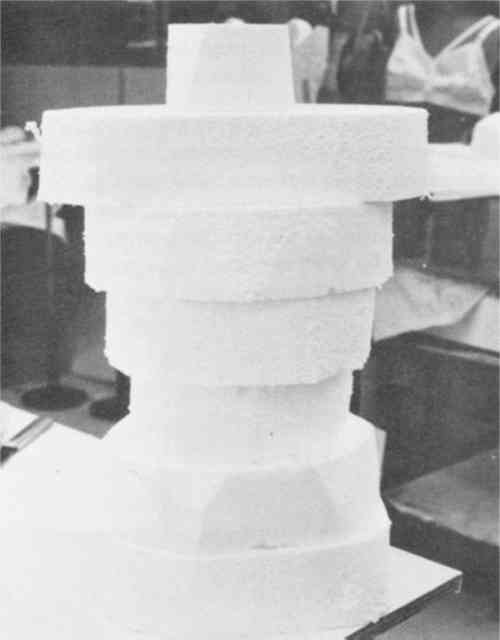

- The discs are adhered together with the 3M brand EC4693 and stacked, at which time a variation can be made to accommodate a particular period body stance. (See figure 8.)

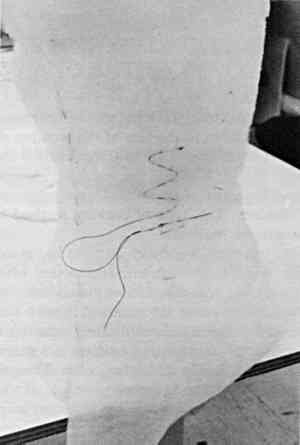

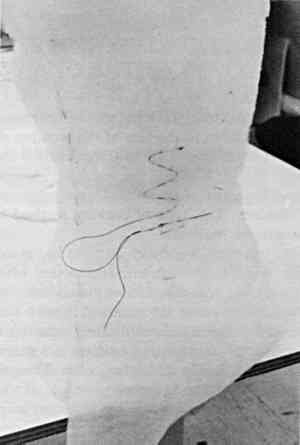

- When the cement has set the torso is carved to the proper size. Electric meat knives and sharp flexible “Olfa” knives (4 inches or 10cm in length) are quite effective. (See figure 9.)

- During the construction it is necessary to try the costume on. Washed cotton T-shirts are placed on the mannequins to protect the costume.

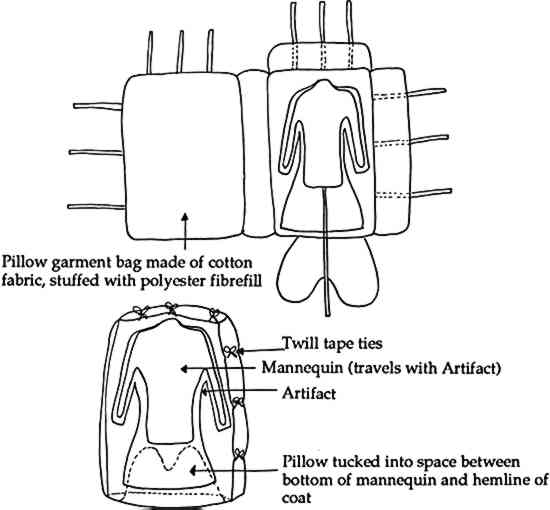

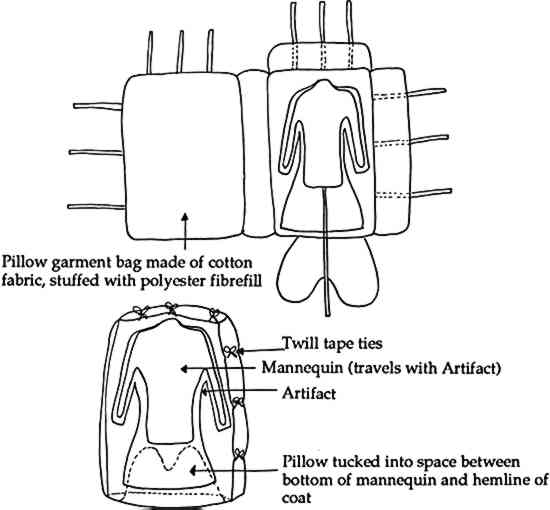

- The finished torso is covered with polyester fibrefill to add a slight cushion. (See figure 10.)

- Surgical cotton tubing (8 inches or 20cm) used for casts is used to cover the mannequin. Three-inch (7.5cm) tubing is stuffed with polyester fibrefill and used to make arms.

- To display the mannequin, a rod is inserted into its centre, or a wooden base is made which can accommodate a stand.

Fig. 7.

|

Fig. 8.

|

Fig. 9.

|

Fig. 10.

|

Fig. 11.

|

This method is favoured for historical women's costumes since the mannequin is made to custom-fit the costume. It has been used as well for men's and children's costumes with excellent results. It is fairly inexpensive (approximately $30–$40 Canadian per mannequin); however, a bulk order of supplies must be made in order to reduce the unit price. The number of man-hours required to construct a mannequin varies with the level of expertise of the technician, but it usually requires four to six hours for beginners and three to four hours for more skilled workers.

|