PAPER COMPLEXITY AND THE INTERPRETATION OF CONSERVATION RESEARCHAntoinette Dwan

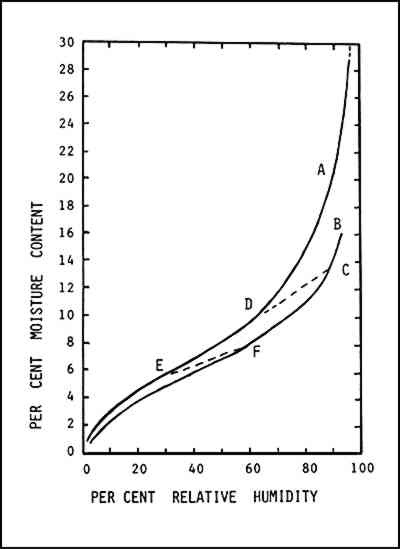

5 PAPER-MOISTURE RELATIONSHIPSTHE RATE AND AMOUNT of moisture regain is dependent on time and the chemical source of the cellulose. The more crystalline the paper, the lower the capacity for absorption. Moisture uptake is greater in papers with higher hemicellulose or lignin content. It is also greater in papers altered by chemical treatments which reduce crystallinity,20 such as oxidative bleaching. Moisture content depends not only on chemical constituents and physical properties, but also on the manner in which the paper was brought into equilibrium. There is a different moisture content at any given relative humidity depending on whether the moisture was desorbed (brought into equilibrium from a higher relative humidity) or adsorbed (brought into equilibrium from a lower relative humidity). The curves for desorption and adsorption are not the same. This is known as the hysteresis effect, and is shown in Figure 11.21

Figures 12, 13, and 14 show hysteresis curves for samples of three types of paper that were properly preconditioned. Each of these figures demonstrates that the data obtained is different at any relative humidity depending on whether the measurement was made after desorption or adsorption. Conservation studies that compare before and after aqueous treatments of any type (humidification, steaming, bathing) are analogous to this situation. Interpretation of test results must account for the magnitude of change in results due to hysteresis effects. Crook and Bennett demonstrated the effect of hysteresis on fourteen papers through numerous tests. They state:

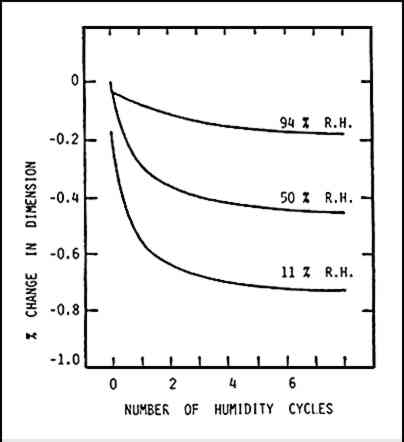

Prior history of moisture gain and loss also affects moisture regain capacity and paper properties. Since paper is a viscoelastic material, it does not return to the same dimensions after drying and rewetting, or after humidity cycling. There is a progressive change in dimension after each humidity cycle, with the greatest change occurring after the initial cycle.23(Figure 15)

Wink studied dimensional changes in linen writing paper during changing relative humidity conditions. He exposed samples to the humidity cycle of 50%, 11%, 50%, 94%, 11% in increments of about 15% R.H. He repeated the cycle eight times, with the temperature at 73�F. Wink found appreciable shrinkage at the three relative humidity levels. The curves show that the stress-relaxation effect dominates the swelling effect to such a degree that all dimensions at 94% relative humidity were smaller than the initial dimensions at 50% relative humidity.24

Moisture is so critical to the properties of paper that the TAPPI standard for temperatures and moisture require a temperature of 23� � 1�C and a relative humidity of 50% � 2%.26 The TAPPI standard acknowledges the discrepancy caused by the hysteresis effect in moisture content and recommends preconditioning the sample from below 50%, by absorption. This same standard emphasizes the effect of preconditioning and the hysteresis effect in the section, “Importance of Preconditioning”:

Crook and Bennett emphasize the importance of the hysteresis effect when they conclude: Researchers often use handsheets prepared in the laboratory under controlled temperature and relative humidity conditions. The use of handsheets eliminates effects caused by the unknown history of humidity cycling, hysteresis, moisture content, creep, and stress-relaxation. The use of papers other than handsheets (for instance historical papers) presents unknown variables making correct interpretation of data complex or impossible. |