NOTE ON A FILL MATERIAL FOR WATER SENSITIVE OBJECTSPAMELA HATCHFIELD

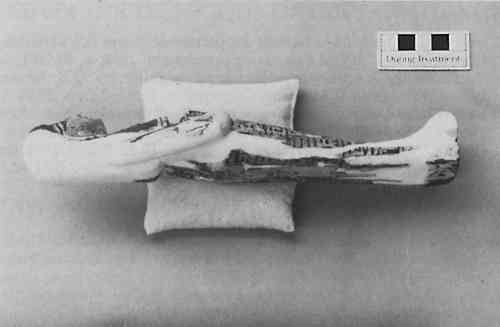

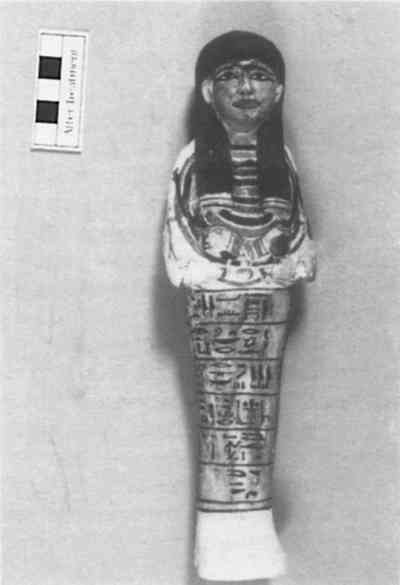

ABSTRACT—The use of glass microspheres in Acryloid B-72 is discussed as a gap filler for water sensitive materials. The reconstruction of a polychromed wood Egyptian shawabti using these materials is described. 1 INTRODUCTIONConservators have become familiar with glass microballoons primarily as used in air abrasive or peening techniques. They have been used in conjunction with other fill materials, primarily to reduce thermal expansion of setting resins.1 Described as hollow, unicellular soda lime borosilicate glass microspheres,2 this product was developed for industrial use in syntactic (homogeneous, closed-cell) foams, injection molding and autobody repair. The dry microspheres are lightweight, resembling a fine white powder, and the 3M products range in density from 0.15 to 0.40 grams/cm3. They pour like a liquid, and are non-toxic.3 As the glass will not react with most resins,4 it may have a wide range of application in conjunction with materials commonly used by conservators. The spherical shape of the particles allows for a low percentage of resin in the formulation of fill material, and ensures relatively low shrinkage. The bubbles are easily mixed into resins. (They may rise to the top of a mixture during storage, but are readily redistributed by stirring.) The products formulated for general use guarantee that 95% of the particles will be 80 mesh (177 microns) or smaller. Microballoons are available in a range of densities and respective compressive strengths. 2 TREATMENTFIGURES 1–4SHOW THE USE of 3M's lightest grade C15/250 microspheres as a fill material for the reconstruction of a New Kingdom Egyptian polychromed wood shawabti, a burial figure, which had been severely damaged by termites. (Fig. 1). Wood and painted surfaces were fragmentary but generally in good condition. Where the wood substrate had been almost completely eaten away, local consolidation of the painted surface was done with Acryloid B-72 3% in toluene. Joins were adhered with polyvinyl acetate resin AYAF 20% in acetone, or with B-72 50% in acetone. Some joins required a facing support of Tengujo tissue.5

Large voids and unsupported surface pieces required a strong, lightweight fill material which would not affect water-sensitive gesso or painted surfaces, and not be absorbed into porous materials, possibly resulting in ghosting. Due to the fragile nature of the damaged wood and its limited capability to support surviving surface fragments, an easily reversible fill material was required to allow positioning and repositioning of fragments as required during reconstruction. More traditional wood fillers such as plaster or water-based cellulosicor vinylic fillers seemed inappropriate in light of the above requirements. Voids in the figure were lined with Tengujo tissue and B-72 15% in acetone. Equal volumes of the same resin or 15% in acetone/ethanol 1:1 and 3M C15/250 microspheres were mixed to form a thick but pourable fill material which was built up in layers. (Fig. 2). Fills were found to be easily built up, strong, lightweight, and easily shaped by sanding, carving, or application of appropriate solvents. (Figs. 3, 4). Fills may be inpainted with water-based acrylics such as Liquitex, or with watercolors. 3 CONCLUSIONBECAUSE A LOW resin-to-microsphere volume concentration is sufficient to form a cohesive fill, this material was found to be easily reversible with a minimal amount of an appropriate solvent. Ghosting problems associated with plaster or other fillers commonly used on porous materials are avoided, as are potential problems for water sensitive gesso, wood and painted surfaces. This fill material also produced promising results for the filling of marbles and faience. NOTES1. Barkov, Z. and F. Lambert, “Mechanical Properties of Some Fill Materials for Ceramic Conservation,” ICOM Preprints, Copenhagen, 1984, p. 84.20.1. Also noted are the following: A reference to silica beads in Fidler, J., “U. S. Advances in Preservation Technology II,” Building Conservation, 1, No. 2., pp. 27–29, 1979, and a fill material for pottery including epoxy, fired clay and glass microballoons, in Higuchi, S. and S. Imazu, “New Material for the Restoration of Excavated Pottery,” Science for Conservation, No. 23, pp. 19–32, March 1984. (in Japanese). 2. Anon., 3M “Glass Bubbles Specifications” for C15/250, 70-0701-0995-7-(551)R2, p. 1. Available from:

3. The American Council of Governmental Industrial Hygienists classifies this product as a “nuisance dust”. 3M Product Information, “Glass Bubbles Storage and Handling,” 70-0701-0999-9(551)R2, p. 2. 4. Barber, Dr. E.C., “Reduce Part Weight and Cost with Hollow Microspheres for Plastics,” reprinted from Plastics Design and Processing, July, 1978, p.2. 5. Tengujo Japanese tissue is available from TALAS, 213 W. 35 St., NY, NY 10001. Rohm and Haas resins B-72 and PVA-AYAF are available through Conservation Materials, 240 Freeport Blvd., Box 2884, Sparks, NV 89431.

Section Index Section Index |