VAPOR PHASE CONSOLIDATION OF BOOKS WITH THE PARYLENE POLYMERSBruce J. Humphrey

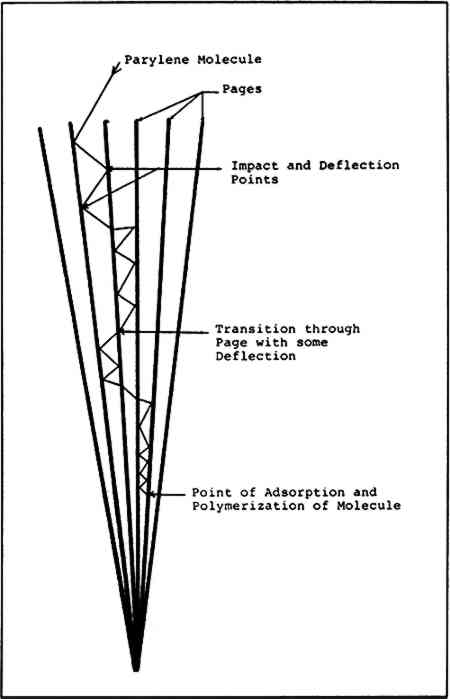

5 A REVIEW OF TECHNICAL PROBLEMS POSED BY VACUUM POLYMERIZATION IN BOUND VOLUMES5.1 Apparent vs Micro-Surface Area of PaperA book measuring 19 � 13 cm which contains 400 numbered pages consists of 200 individual leaves, each of which has an apparent surface area of 494 cm2. The entire book will then have an apparent surface area of almost 102,000 cm2 or a little over 10m2. This includes the covers and protective inner leaves which are not numbered but must be included in the surface area measurements. Apparent surface area, then, is that area which is readily apparent to the unaided eye. The microscopic surface area however, can be several times larger than the apparent surface area depending on the type or composition of the paper being treated. It is this microscopic surface area—consisting of millions of individual cellulose fibers—which is relevant and important when discussing parylene deposition and polymerization. It must be remembered that parylene polymerizes on a molecule by molecule basis. The parylene molecule is approximately 35 � 20 angstroms in size and it is at this level of size that coating and consolidation initiates. Parylene will coat all the surface area available down to this level of scale. What this means is that larger amounts of parylene will be required to coat this micro surface area. It also means that very initimate contact with a substrate will occur. This is one of the reasons for the irreversibility of the process: contact with the substrate is so initimate and on such a minute scale that removal without damage to the paper would be impossible. 5.2 PenetrationThe strengthening of paper which is bound in book form poses a considerable challenge to any consolidant. In an ideal case, the polymer should penetrate and polymerize equally on all parts of a book. Using parylene, it is not possible to accomplish this with the book closed. A book processed in the closed state would become bound on all edges due to “polymer bridging” from one page to another. This would in turn form a barrier to further penetration of the parylene and the desired strengthening would not occur. The book must be processed while open, and the leaves arranged so that there is some interval maintained between each of the leaves to allow entry of the parylene molecules. Once all these criteria are met there is still the problem of “diminishing interleaf spacing.” The distance between any two adjacent leaves might range from .5 to 1.5 mm at the outer edges of the book. This distance diminishes to almost zero at the binding. In order to treat fully a bound volume, parylene molecules must find their way to the bottom of all the multiple crevices created between leaves due to their being bound at one edge. Figure 4 is a diagram illustrating the hypothetical path of a single parylene molecule entering a book and traveling some distance toward the binding before finally adsorbing and polymerizing on the surface of a page. It is interesting to note that parylene molecles will pass between paper fibers with varying ease depending

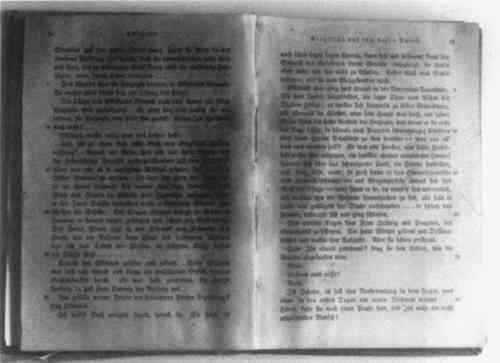

5.3 Gaseous Diffusion Through PaperThe gaseous diffusion of parylene through paper was tested by sealing test substrates (an aluminum or glass strip) inside cubes made from newsprint and foldur kraft paper. After treatment the cubes were opened and the substrates checked for the 5.4 Polymer Thinning in Bound VolumesAs noted earlier, the parylene molecule is very active. The molecule will bounce off the substrate many times before the proper kinetics and angle of impact occur, resulting in adsorption and subsequent polymerization. The very close spacing of the pages greatly increases the number of “molecular impacts” and hence greatly increases the chances that a molecule will adsorb and polymerize before reaching the inner portions of a book. As a result the coating is thickest at the outer page boundries and grows thinner toward the center binding edge of each page. This halo penetration effect can be seen in Figure 5. The dark area in the center has not been coated due to an insufficient penetration of polymer.

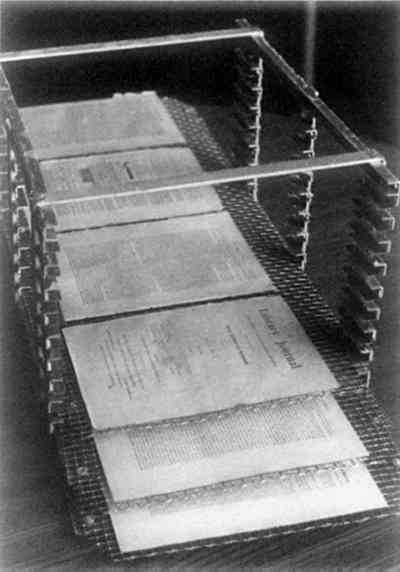

A further explanation for this thinning effect is that polymer which has already adsorbed and polymerized in the outer areas of the book tends to operate as an additional “sink” for the free parylene diradicals still in the gas phase. In simple terms, In order to determine the amount of thinning which might occur at a specific treatment level the following test was conducted. A book was selected and test strips were placed at the edge, middle and binding side of several pages throughout the book. The book was then placed in a chamber and sufficient parylene added to allow for penetration to the binding edge of the pages. After removal from the chamber the test strips were measured. The test strips indicate that the thickness ranges from 2.5 microns at the outer edge to .5 microns near the binding. At this point in the research it appears to be impossible to avoid this gradient in bound books. Uniform coatings of any desired thickness can be obtained by disbinding the book and processing the individual pages on trays 3–5 mm apart—a rather costly procedure. (Fig. 6).

If the gradient remains constant from book to book, which has yet to be demonstrated, the desired thickness could perhaps be extrapolated from readings taken at the outer edge of the pages. The ratio derived from this work appears to be 5:1 in this case. A 5 micron reading at the page edge indicates that 1 micron should coat the paper at or near the binding. It appears that in order to obtain desirable coatings near the binding edge, heavier amounts must be accumulated on the outer periphery of the pages. |