YELLOWING AND BLEACHING OF PAINT FILMSHenry W. Levison

ABSTRACT—Experiments are described, demonstrating that exposure to daylight will bleach out dark-induced yellowing from drying oils in paint films, and that the degree of darkening and its susceptibility to bleaching is not a function of the age of the paint film or previous darkening and bleaching cycles. Three different drying oils and also acrylic emulsion mediums were tested. THE YELLOWING OF DRYING oils in artists' paints in the dark and their subsequent bleaching in sunlight has been known qualitatively for centuries.1 Objective measurements, however, have been sparse and only recently accomplished. In 1972 Phillips related his experience with the bleaching of centuries-old linseed oil interior wall paints that had been darkened by being painted over.2 The author published the results of one cycle of the yellowing and bleaching of artist's white paint in 1976,3 and two cycles in 1978.4 In 1979, Rakoff, Thomas and Gast made detailed measurements on white linseed oil house paints over three cycles.5 In the same year, Tahk published a related series of tests on heat-induced discoloration and the subsequent photobleaching involving a variety of mixtures of white and colored artist's oil paints.6 The work to be described here demonstrates that only a brief exposure to indirect north light will almost completely bleach out the yellow discoloration built up over several years at normal ambient temperatures in the dark. Whether such a procedure would prove ultimately detrimental if repeated often enough, is a matter that must be investigated. Data are provided on the yellowing and bleaching of a variety of vehicles for four cycles over long periods of time. The yellowing of the paint films occurred during storage in the dark. Subsequent bleaching was accomplished by exposure to diffuse daylight indoors. That the yellowing observed in these tests corresponds to the discoloration that occurs over the years from normal indoor illumination is suggested by the yellowing of white oil paint films aged in normal daytime indoor illumination for thirteen years.7 Under such conditions, the net change in yellowness index was found to be of the same order of magnitude as that which was measured in the present tests. After four cycles in the dark, the 3�-year-old-year-old paint films in the present series could still be bleached, within experimental error, to their initial whiteness. Three different drying oils in white paints were used, and a variety of artists' painting mediums were added to a standard white oil paint. Artists' painting mediums are materials that may be added to tube paints to alter the handling properties, to provide flow, to make transparent glazes, or to enhance chromatic properties; a relatively non-yellowing white is used as the standard base to which the painting mediums were added. The acrylic emulsion paints have mediums for similar purposes and several were included in the present investigation. The composition of the artists' paints and of the painting medium mixtures are not inherently different from the composition of trade paints and, therefore, it may be assumed that the results are directly applicable to trade paints used indoors. The addition of a drying oil to a medium oil length alkyd, for example, merely makes it a long oil alkyd. That drying oil films yellow more the greater the unsaturation of the oil is well known. The discoloration is particularly perceptible in whites and light tints. As a result, the old masters ground their white paints in walnut oil at an early date, and later in popyseed oil. More recently safflower oil has been employed. These oils have a much lower degree of unsaturation than the linseed oil commonly used in the artists' colored tube paints commercially available. 1 PREPARATION OF TEST SPECIMENSTHE TESTING PROCEDURE WAS developed from previous experience. For the short term tests it is easiest to use the lacquer-covered paper opacity charts. For the long-term exposures, however, the lacquer coating on these charts significantly discolors irreversibly, confusing the results. Therefore, white art posterboard coated with a medium oil length soya alkyd white was used for the longer tests. The formulation of the white paint is as follows: Table 1 Composition of White Ground Paint for Test Panels The ground coat paint was thinned with mineral spirits for flow coating or for spraying the full sheet of posterboard on the highly finished side. Two ground coats were applied to insure complete opacity. After aging a month or more, the sheets were cut into 3″ � 6″ panels for the application of the test paints. With the oil mediums, the specimens were made by mixing equal weights of the oil in the standard mixing white paint (Table 3) relative to the non-volatile in the painting medium. With the acrylic emulsion mediums one part of the medium was mixed by weight with two parts of a proprietary acrylic emulsion titanium white paint. Table 3 Standard Mixing White Oil Paint In order to obtain the mixing weights of the oil painting mediums it was necessary to determine the non-volatile content.8 The non-volatile content of the oil painting mediums used in this test is given in Table 2. Table 2 Percentage Non-Volatile Content of Oil Painting Mediums Tested Zinc oxide was present in the oil mixing white to make certain the safflower oil dried normally and to insure retention of whiteness. The 100% non-volatile mediums were thinned with mineral spirits to 50% non-volatile to produce draw-downs comparable in thickness with mediums containing a thinner. No. 16, with its very low non-volatile of 6.3%, requires 3.56 times as much medium as the standard mixing white paint and not only is difficult to draw down because of the preponderance of thinner, but produces a film thickness of 44% of a non-volatile paint draw-down. All the other white oil paint-mediums mixtures produce a film of 70% thickness or more. The test film produced by No. 16, consequently, is not comparable with the test films of the other mediums. In the test series (Table 4) Nos. 1 through 20 are mixtures of painting mediums with the standard mixing oil white (Table 3) at equal weights of oil in the white to the non-volatiles in the medium (except No. 16 as noted). The acrylic mediums, Nos. 23, 24 and 25, were mixed one part by weight to two parts of LIQUITEX Acrylic Titanium White. Nos. 26 through 32 were tested directly as received. Table 4 Mediums and Paints Tested The specimens to be tested were drawn down with a two inch wide applicator having a 0.0025 inch clearance on the panels previously coated with two coats of white ground paint. The drawn-down test panels were aged six weeks in good light near a window. The initial Yellowness Index (Y.I.) was then measured. The Y.I. calculated as follows, was determined from the tristimulus Values X,Y,Z (CIE 931) measured with a Kollmorgen D-1 large sphere Model Color-Eye� colorimeter. Yellowness indices below 4 were not readily detectable visually.

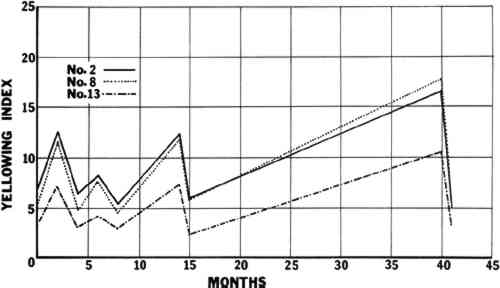

After the initial Y.I. reading the panel was placed in the dark. After removing from the dark, the Y.I. was again determined and the panel exposed to the light. After this bleaching period the Y.I. was again measured and the panel again placed in the dark. The specimens were subjected to four cycles of dark followed by light. For the dark period the panels were stacked, the top and bottom covered with white posterboard the same size, and the assembly held together with rubber bands. The stacked panels were thus stored on a laboratory shelf at ambient temperatures of The first three exposures to the light (periods of bleaching) were obtained by hanging the panels vertically at right angles to a window, facing east, in a position where the sun did not strike the specimens. For the latter two-thirds of the day the sun did not even strike the glass. The level of diffuse illumination on the specimens varied from 10 to 100 footcandles. The panels were exposed in this manner for 60 days after each of the first two dark cycles of 60 days each, then for 30 days after the 180-day dark cycle. The fourth period of light exposure occurred after a location move. In this case, the panels were hung facing a north window, 36 inches away. This was at a time of the year when the sun never directly struck the window; nonetheless, the northern exposure produced an illumination level of from 200 to 300 footcandles. The period of exposure to light here was only 30 days. Rakoff, Thomas and Gast found no difference in the results of exposure facing south and north. Tahk found fluorescent lamplight effective in both the visible and ultraviolet range.11 Table 5 gives the measured yellowness indices, Y.I. through four cycles, following each period of storage in the dark and following each bleaching in the light. See also Figure 1. No perceptible yellowness was seen in any of the acrylic specimens. Table 5 Yellowness Indices After Dark and Light Exposures

2 DISCUSSIONAFTER THE FIRST CYCLE, when the Y.I. was only approximately two-thirds of the initial Y.I., it was thought that a trend of reduced yellowness had begun.12 That was dispelled, however, by the results in subsequent cycles. The age of the films of drying oils did not diminish the degree to which the films eventually became discolored. The bleaching appeared to depend on the intensity of the illumination or, more precisely, the net exposure (intensity times time) in a period of 30 days. The excellent window illumination following the greatest increase in yellowing (fourth cycle) bleached the panels close to the initial whiteness. This result particularly applies to the linseed oil white, which yellowed the most, but became visibly whiter than it was initially. It is interesting to compare three mixtures that have the same proportion of linseed oil in their compositions, Nos. 2, 8 and 13. This allows comparison of the effect of run copal, maleated rosin ester (substitute for copal) and soya alkyd. The yellowing of the maleated rosin ester fell slightly below that of the copal mixture although it seems be slightly higher after 25 months in the dark. However, this vehicle bleached to the same Y.I. as the copal. The soya alkyd mixture, on the other hand, yellowed much less throughout and bleached to the same original whiteness, making it the formulation that exhibited the least tendency of these to yellow. Undoubtedly, yellowing in the dark is the result of thermally induced oxidative reactions. Some years ago, Huey described a method of storing standard reference paint panels in the cold and under an inert atmosphere in order to minimize their discoloration in the dark.13 Museums and artists may not wish to store the paintings in their collections at particularly low temperatures or in an inert atmosphere, but they might consider storing them at a lower-than-normal temperature. Moreover, they may also wish to consider the centuries-old practice of exposing yellowed oils to indirect daylight or to filtered fluorescent lamplight for brief periods to reverse the yellowing of the vehicle which may have occurred over several years of storage in the dark. The present work has demonstrated that very brief exposure to indirect north light will 3 CONCLUSIONTHE MOST IMPORTANT CONCLUSION from this investigation is that the net degree to which films are capable of discoloring in the dark does not seem to be a function of the age of the film or the extent and frequency of photochemically induced bleaching the films may have undergone in the intervening time. Moreover, in spite of as many as four cycles of discoloration in the dark and subsequent bleaching, the discolored films The alkyd mediums exhibited the least yellowing throughout, followed closely by the paints made with safflower or poppyseed oil. The linseed oil paint yellowed the most, but recovered extremely well. The extent of discoloration in the case of the painting mediums apparently was related to the content of linseed oil. On the other hand, resins, other than the alkyds, do not appear to affect the degree of yellowing if the initial color due to the added resin is taken into account. If cobalt drier is used in the minimum effective amount, its effect on yellowing was not noticeable. In all instances, the mixtures containing cobalt drier bleached as though they were without drier. With the zinc-zirconium drier in the safflower oil paint, the initial yellowness was less than the yellowness of the paint without drier and continued that way throughout four cycles. REFERENCESGettens, R.J. and Stout, C.L., Painting Meterials, Van Nostrand, New York, 1952, p. 42. Mayer, Ralph, The Artist's Handbook, Viking Press, New York, 1970, p. 175 Phillips, Morgan W. “Problems in the Reconstruction and Preservation of Old House Paints,” Proceedings of the North American International Regional Conference, Smithsonian Institution Press, Washington, D.C., 1976, p. 273. Levison, H.W., Artists' Pigments, Hallandale, FL, 1976, p. 31. Levison, H.W., Color, Research and Application, Vol. 3, No. 1 Spring 1978, p. 7. Rakoff, H., Thomas, F.L., and Gast, L.E., Journal of Coating Technology, 51, No. 649, 1979, p. 23. Tahk, Christopher, “The Recovery of Color in Scorched Oil Paint Films”, Journal of the American Institute of Conservation, Vol. 9, 1, Fall 1979, p. 3. See reference 3, p. 10. ASTM Test Method D 1644, Non-volatile Content of Vehicles. Mayer, Ralph, The Artist's Handbook, Viking Press, New York, 1970, p. 216. ASTM Test Method D 1925, Yellowing Index of Plastics. See reference 6, p. 5. See reference 3, p. 31. Huey, S.J., “Low Temperature Storage of Colored Standards Panels,” Color Engineering, September-October 1965 pp. 24–27.

Section Index Section Index |