TREATMENT AND MOUNTING OF A POSTER ANGLETERRE BY A.M. CASSANDREAntoinette Owen

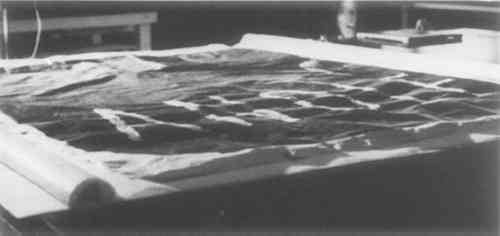

2 TREATMENT OF QUADRANT #2THE BOTTOM LEFT QUADRANT, referred to as quadrant 2 in Fig. 1, was the first of the four quadrants treated. The vertical strips (quadrants 1,2 and 3,4) were separated into quadrants by applying moisture to the overlapping sheets. The surface of quadrant 2 was dry cleaned with finely powdered eraser crumbs to remove the surface dirt. Pressure-sensitive tape was removed either mechanically or by using acetone if the Separating the poster from the cloth was the first step in structural treatment. So that the poster and backing could be soaked in water, a large washing tray was constructed of polyethylene sheeting supported at the sides by wooden 2-by-4s joined together with metal right-angles and screws. A rigid fiberglass screen stretched onto a wooden frame was constructed as a support for the paper quadrants during aqueous treatment. Quadrant 2, supported face down on the screen and cushioned with a sheet of wet strength tissue, was placed into the tray and allowed to soak in deionized water1 (brought to pH 8.5 by the addition of calcium hydroxide solution) for 1� hours. Attempts to remove the cloth were then begun. This process was more difficult than anticipated; the adhesive was thickly applied and in many areas the water did not by itself loosen the bond between cloth and paper. If mechanical manipulation of the cloth did not release the bond in these tenacious areas, the cloth was cut out and left attached to the verso of the poster. In most areas the cloth could be removed after prolonged soaking and manipulation; a gray adhesive layer contaminated with wood chips and other accretions was noted. When the cloth backing was finally removed, the poster was placed in a fresh water bath and allowed to wash another 1� hours. It was hoped that this bath would reduce the starch adhesive. However, upon removal from the bath and air drying, the poster was extremely distorted (Fig. 3). Two types of distortions were now evident:

It was felt that the overall distortions could be remedied by dissolution of the adhesive from the verso, while the inherent distortions created by the ink layers could be remedied by a friction/tension drying method. The tenacious adhesive was resistant to warm, alkaline (pH 8.5) water, and the paper had little wet strength to withstand scraping of the adhesive. Tests made with enzymes specific to starch indicated that the adhesive would easily break down under enzymatic action without affecting the paper or inks. The enzyme selected for the treatment was Alpha Amylase type IIA (bacillus subtilis) from Sigma Chemical Corporation.2 This enzyme operates most efficiently at a solution pH of 6.9 and within a temperature range of 37–39� C. Chemical buffers are often recommended to maintain the proper solution pH because often the acidity of the art object, if it remains in an enzyme solution for an extended period of time, will shift the solution pH. In this case, however, the type IIA enzyme solution was found to work extremely efficiently without the addition of the sodium phosphate buffer solution. A possible explanation may be the rapidity of enzymatic action with type IIA (15 minutes for each 5′ by 4′ quadrant using a .01% solution at 39�C). In the short period of time necessary for the enzyme to hydrolyze the amalose fraction of starch, the pH may not have begun to shift significantly. It should be mentioned that the enzyme solution used was given a slightly higher pH initially (7.2 with calcium hydroxide solution as opposed to 6.9 recommended in the literature), with the expectation that dissolution of the adhesive into the solution would cause a drop in pH. Quadrant 2 was treated with a .01% solution of Alpha Amalase type IIA. At the end of 15 minutes, tests made on the verso using the iodine/potassium iodide stain indicated that the amalose chain of the starch was completely hydrolyzed (no blue/purple stain was visible). The quadrant was rinsed, water washed for 1� hours, then dried between blotters. A comparison (Fig. 4) with the earlier photograph (Fig. 3) shows that the overall distortions disappeared, with only those around the letters remaining.

|