ON COPYING BRONZE STATUETTESAnn H. Allison, & Robert B. Pond

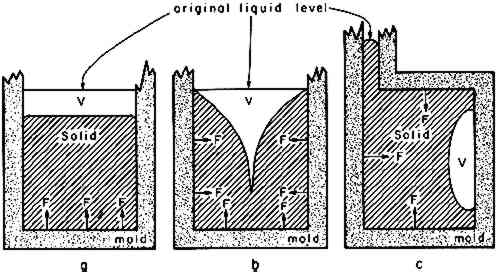

2 GENERAL TECHNIQUETHE GENERAL TECHNIQUE for generating a copy of a metal casting involves a number of steps which must be carried out in a rather exacting manner in order to produce a Step 1. The model to be copied is studied to determine the number of pieces which will be required to generate the piece mold. In this decision there are two points to be considered: 1, the number of mold pieces should be kept at a minimum and 2, no mold piece should be shaped so that it tends to retain any part of the model during separation. Step 2.The various mold pieces are cast in Plaster of Paris so that they form fits on parting lines and can be reassembled in only one way. This is easily accomplished by encasing in soft clay that part of the model from which the first mold piece is not to be made. The soft clay can be worked to the parting line desired in a leisurely manner since it does not become hard until its water (or other vehicle) evaporates. The model is oiled, greased or waxed so that when the plaster which is cast against it hardens, it can be easily parted fromthe model and the soft clay. After the plaster of the first mold piece hardens, the soft clay encasement is removed from that part of the model to be copied by the second mold piece. The plaster of the first mold piece is oiled or greased so that the second plaster casting will not stick to it. The second piece of the mold is cast and the above procedure continued until the entire model is encompassed by the various mold pieces of plaster. These pieces are removed from the model and reassembled to form a cavity which is the three dimensional negative of the model. Step 3. If the piece mold is to be preserved, then it is used to make a wax replica of the model. This is accomplished by filling the piece mold cavity with molten wax. The plaster must be imbibed with water to insure that the wax will not wet (or be absorbed into) the plaster. The wax will begin its solidification at the cold plaster surfaces and the solid wax will form as a shell. When this shell reaches the thickness desired by the artisan, the excess liquid wax is decanted. The plaster piece mold is removed and can be reused to make more wax replicas. The wax replica shell may be dressed of excess wax such as the flash which exists at the parting surfaces of the piece mold. It is now ready to be invested in a seamless plaster mold which will be used as a flask for the metal casting. Step 4.The plaster which will fill the inner part of the replica wax shell (the core) may need some lateral support once the wax is removed. This support is provided by pins or rods, which are inserted into the wax replica at appropriate points so that they extend from the surface and into the cavity. Rods, tubes or blocks of wax are attached to the wax replica at the point where the molten metal is desired to be fed as well as those points where there may be a gravity entrapment of gas or a sufficiently large section to sponsor internal transformation shrinkage (to be discussed later). See Fig. 1. Step 5.The wax replica is now invested in Plaster of Paris or a mixture of plaster and some aggregate such as silica or quartz sand. After the plaster has hardened the wax is rendered from it by elevating the temperature so that the wax shell melts and flows out. Step 6.The hollow plaster flask is geometrically but not chemically ready to serve as a mold for metal casting, as it is wet and must be dried. Air So that the metal will begin its solidification at the mold surface, the mold must be lowered from the high temperature of calcining before the casting operation. If this cooling is carried out too rapidly, there can be a resulting cracking of the mold. Step 8.The molten alloy is cast into the mold in a continuous and rapid manner. After cooling to room temperature the investment is removed from the metal casting and it is finished by sawing off the vents, gates, pins and sprues, all of which were purposely placed, as well as any flash resulting from cracking of the mold. Fine tooling by filing, abrading, burnishing, chiseling, scraping, etc., is also necessary. This ancient cire perdue method, described in many writings, is presented in great detail by Choate.2

A good statuette copy should have dimensional fidelity to the original. However, a copy produced in a mold taken from the original model will be smaller due to the shrinkage of the metal. If such shrinkage were uniform and not affected by factors disturbing the constancy or by pre- or post-casing modification, it would be very simple by careful comparative measurement to document the original, first copy, second Offhand, one might imagine that, if this process is properly carried off, the statue will be different in dimension only by shrinkage of the alloy from its molten state to its solid room-temperature state. This, however, is not the case. The total shrinkage (ST) from the original dimensions is a function of several variables and can be represented as:

Neiman3 in his discussion of shrinkages and methods of compensation peculiar to copper alloys states that the caster has four types of dimensional change to consider:

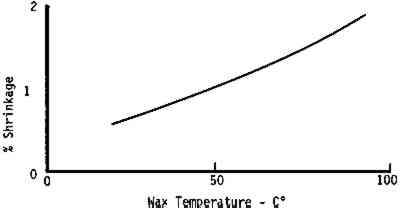

The expansion of the plaster during setting and heating is explained by Skinner and Philips4 as resulting from silica incorporated as an aggregate with the plaster. A number of experiments have been carried out to determine how the shrinkages (A, B, C, D above) change with varying conditions. Figure 2 indicates that the shrinkage of the wax pattern is definitely a function of the temperature of the wax when cast.

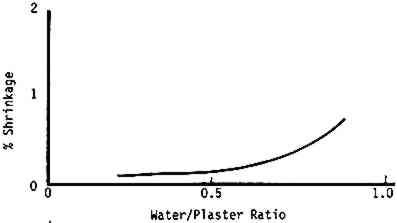

Figure 3 indicates that the shrinkage of the plaster in setting is a function of the water to plaster ratio.

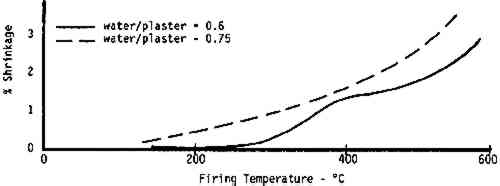

Figure 4 indicates that the shrinkage of the plaster on firing is a function of water-plaster ratio and the temperature of firing.

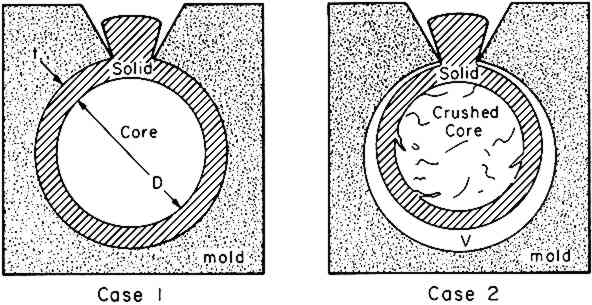

A good artisan would not heat the wax any higher than necessary. Overheating will not only cause excessive shrinkage but will also cause evaporation of water from the surface of the piece mold with a resulting porosity of the wax pattern. A good artisan would also avoid the use of high water-plaster ratios since excessive water will cause great shrinkage as well as cracking of the plaster flask. In considering the shrinkage (D) of the metal, attention should be directed to the mechanism of solidification of alloys. It is not uncommon for metals and alloys in the molten state to have absorbed gasses which upon solidification are rejected from the metal. It is possible in molten alloys to have a gas generating reaction in the liquid state which continues even during solidification. Frequently, water trapped in the mold is gassified by the molten metal striking the mold. The presence of such gasses trapped in the casting are generally referred to as blow holes unless they are of very small A large shrinkage occurs when most metals and alloys transform from the liquid to the solid state. If this shrinkage is contained within an already solidified portion of the casting so that no liquid metal can be fed to the shrinking volume, then a cavity is formed which contains a vacuum. If this cavity is near a surface, the solid metal can be deformed inward to relieve the vacuum. These cavities are referred to as shrinkage cavities. If they are continuously connected throughout the casting, they are referred to as pipes. The shrinkage of a casting must not be confused with either the density or porosity of the casting (see Hesse 5). A casting may be only 85% dense because it contains many shrinkage cavities, blow holes, etc., and yet the shrinkage from the model may be only 2%. A good casting will be fed during solidification by properly placed tubes and risers. Therefore the transformation shrinkage in a good casting should contribute nothing to the shrinkage of the casting. The shrinkage of a good casting comes only from the solid state shrinkage of the alloy. The casting shrinkage of the copper alloys is shown by Neiman to be contained in a narrow band. Table I sets forth an array of such values of shrinkage. These values are derived from solid state shrinkage alone. If the shrinkage of the wax pattern and the contraction or expansion of the investment were added to the values of Table I, they would be consideraly altered. A cylinder model was copied in two different brasses by the cire perdue method using no silica in the plaster. The shrinkage values obtained are 2.5% for the semi-red (5-A) brass and 3.18% for the yellow (6-C) brass. Table I In considering the shrinkage in the alloy as it moves from the liquid to the solid state, attention should be given to the direction in which solidification proceeds. By reference to Fig. 1-a, it is noted that, when there is a planar liquid-solid interface travelling in only one direction, the volume change differential is maintained in the last material to solidify. If the waste mold is properly gated and risers of the correct volume and position are provided, then the transformation volume change is contained in the risers and does not contribute to the shrinkage noted in the finished copy. However, if conditions are not provided for the proper direction of solidification and/or proper gate and riser techniques are not used, then the liquid-solid transformation shrinkage can be retained in the statue copy and lead to undesired, localized increased shrinkage in the copy, as seen in Fig. 1-b and 1-c. Therefore, if good practice is maintained, the shrinkage from the original model will be that generated by the wax and plaster techniques plus that generated in the solid state as the alloy cools from its melting point to room temperature. If a solid casting or a slush casting∗ is made, solid state shrinkage proceeds uninhibited. However, if the copy is made with a thin wall by the use of a core, shrinkage of the casting is inhibited by the core. If the core has a high crushing or compaction strength, it will not yield to the shrinkage of the metal shell and will cause the hot thin metal wall to flow plastically and thin rather than shrink. In this case the apparent solid state shrinkage will be less than expected. This can be understood by reference to Fig. 5: in Case 1 the shell is deformed, but in Case 2 the core is crushed. To find the extent of upsetting or crushing, one must consider the relative coefficients of thermal expansion. If both the core and the shell (casting) had the same coefficient

∗A slush casting is made by filling a coreless flask with molten material and decanting after the solidified shell becomes sufficiently thick. The wax models described above are the result of slush casting of wax.

It can be concluded that with the qualifications given above it would be improper to make a single comparison of a dimension on a model and its copy to determine the extent of shrinkage. The best approach would be to take many measurements and make the comparison on summary basis. |