THE EXAMINATION OF WINTERTHUR WALLPAPERS AND A PROGRESS REPORT, APRIL 1980, ON A GROUP OF PAPERS FROM THE FISHER HOUSE, PHILADELPHIAAnne F. Clapp

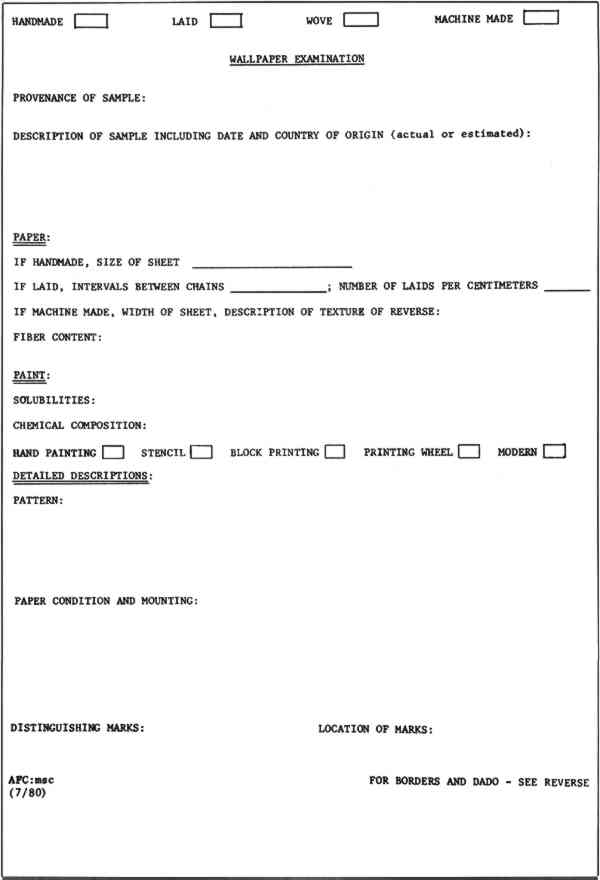

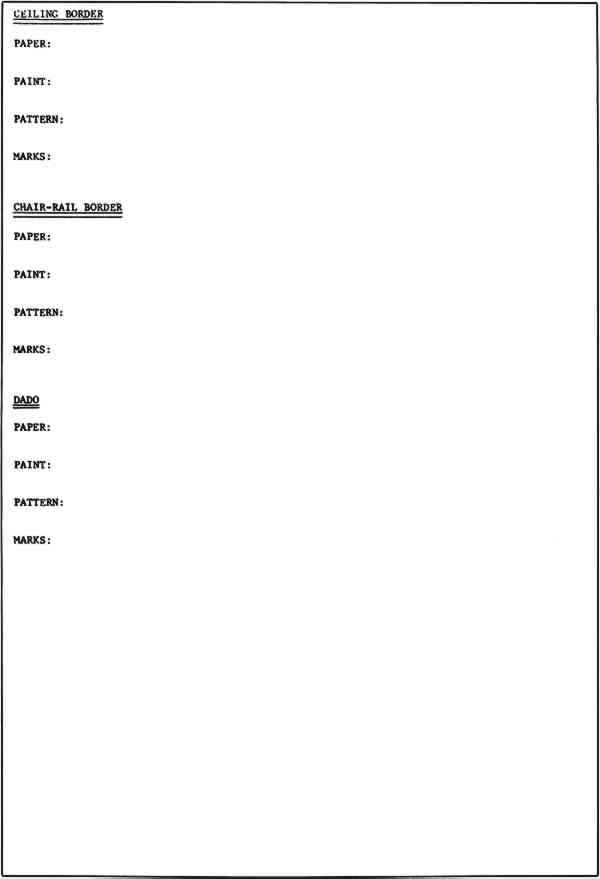

ABSTRACT—A description of the routine examination of paper artifacts is given as it is applied to wallpaper. The salient changes in the history of wallpaper, its manufacture and design, are outlined, together with other factors whose physical presence helps in the dating of unknowns. For the further understanding of the methods and materials associated with wallpaper, detailed information is being gathered on examination forms, a copy of which is illustrated in the article. The procedures used for the study of fibers, the needed reference books and identification stains are described. The initial results are given of the identifications of pigments, by the x-ray fluorescence spectrometer, as used on a series of papers, 1795–1855, taken from the Fisher House, Philadelphia. WINTERTHUR IS AN OUTSTANDING EXAMPLE of a museum that uses the period-room type of display for its wealth of furniture and decorative arts. Its founder, Henry Francis duPont, a man of exacting discernment, placed serious importance on the installation of suitable wall-coverings for the large number of rooms that represent many different periods and qualities. Consequently the museum is well-endowed with mounted wallpapers appropriate to American domestic interiors of the late 18th and early 19th centuries. However, the collection was made at a time when even the most enlightened owner viewed the coverings not as skillfully made artifacts whose integrity should be maintained, but rather as surface decorations of the desired patterns and origins. Their condition at purchase was not thought to be of great concern. Loose paint at the time of mounting and flaking caused by uncontrolled environmental conditions were periodically brushed away, the resultant extensive losses compensated by free-handed artists. If there was not enough of the original edition to cover the required space, insertions were made with later editions or reproductions or by hand-copying. Because of the presence of so much prime material and the various modifications, the study of wallpaper has become one of the interests of the Winterthur paper conservators and, more recently, of the scientists of the analytical laboratory. The examination by the conservator is essentially no different from that used routinely for all papers: establishing the paper size and the method of its manufacture, analyzing the fiber content, determining the technique used in the design, testing for solubilities, etc. Wallpapers can be examined for these factors even if it is still mounted on the wall. If it is unattached, or if a free representative sample is available, the task is easier. Then transmitted light can be used and a search made for identifying marks. Also then, to analyze paint, Winterthur has the benefit of an x-ray fluorescence spectrometer operated by Mrs. Janice Carlson, chemist of the analytical laboratory. Those conservators who have labored through the often-times inconclusive approach to pigment identification by the means of “wet chemistry” techniques will appreciate what an advantage is this quick and non-destructive method whose results are expertly interpreted by a trained scientist. Each one of these determinations can contribute toward the assessment of wallpaper, and each even seems especially appropriate to the assessment. There is a sameness in the manufacture of wallpaper over the years which makes the changes in materials and methods the more salient and gives fairly fixed time-intervals by which the earliest possible datings of unknowns can be established. A few examples will suffice. The Western paper-hanger has evidently been satisfied with the shape of the product he handles, which since the early 18th century has come in long strips, of widths usually between 20 and 25 inches. But in the 1830's, the construction of the strips changed from sections of handmade paper adhered edge-to-edge for a length of about 12 feet to continuous machine-made rolls. Handmade wallpaper that shows the “wove” pattern of manufacture rather than the “laid” can be dated with some confidence after the first of the 19th century, for although wove paper was initiated in the middle of the 18th century, it did not come into common use until shortly after 1800. Even today most of the paper of wallpaper is made of cellulose fibers in the traditional way. But in the late 19th and early 20th centuries, straw and wood, processed in different ways from the natural stock, replaced linen and cotton rags as sources of cellulose. The approximate dates of the introduction of these fibers and processes are known. The structure of the printed designs of the most usual papers has remained practically unchanged—an all-covering base tone on which is placed the design in layers superimposed one upon another, from the paints defining the large areas to those forming small details and highlights. But the method of application turned during the 1840's from hand-applied, wood-block printing to roller printing by machine. The machines have become increasingly sophisticated, and so have left different traces from those of the early ones. During the 19th and 20th centuries, the colorants, from being mineral pigments and natural dyes, reflect the developments of man-made pigments and synthetic dyes. Because the paper of wallpaper, once it has been mounted, functions simply as a necessary interlayer supported by the wall and usually completely covered from view by paint, it was often made of inferior stock. There were exceptions such as Oriental and some early 19th century French wallpapers, notably those from the R�veillon manufactury. For the most part, handmade wallpapers were composed of fibers from the scrapings of the vats, uncleaned rags, reused paper, etc., eked out with “filler stock” such as clippings of unbleached dyed fibers. Because large quantities were needed, especially after the advent of continuous machine-made paper—and it should be noted that wallpaper became popular ar the very time when the amount of rags available to the papermaker could not meet his requirements—the fiber content quickly followed the changes from rags to combinations of rag with straw or soda pulp or groundwood, to the later chemical cooking methods. All these modifications left their marks, so that the study of wallpaper is of value by furthering our knowledge of the histories of methods, materials and design. In the Winterthur study, the information which we should like to determine for each paper is as follows: the immediate source; the origin—country and date, either known or estimated ( if the latter, reasons for the assumption); for handmade paper, the size of the sheet and whether laid or wove; if laid, the distance between the chain lines and the number of laid lines per centimeter; if machine-made, the width of the sheet and its thickness; the fiber content including impurities and fiber-like inclusions; a short description of the pattern and the method by which it was made ( i.e. hand-done, stencil, block print, early printing wheel, modern printing, etc.); the solubilities and chemical composition of the paint; the presence of additives such as mica, flocking or glazes; a photograph or sketch of the repeat, a description of the condition of the paper and its mounting at the time the paper was tested; whether there are borders present, original or later, and if so, to describe the borders in the same way as is done for the main paper. The amount of information we seek may seem large and detailed and its acquisition may seem time-consuming. However, a lot of time and tedium can be saved by form-sheets with titled categories and check-blocks. Figures 1 and 2 show the front and back of the form we use. Needless to say, there are very many instances when much of the information cannot be acquired. Of course, we then fill in only those sections on our examination form which can be accurately answered. If a wallpaper is mounted, for example, it is difficult to see the impressions of manufacture; the principal fibers can be determined by extracting small amounts from an edge or a tear, but the presence of inclusions and impurities often cannot be established; tiny samples of paint can be analyzed by “wet chemistry” if the operator is experienced in that field, but the accuracy and discrimination of the nondestructive x-ray spectrometer cannot be used. Unmounted pieces are sometimes too small to find out much about them except the fiber content and the solubilities and composition of the available paints; even larger samples may not have a full repeat, or its condition may be so poor that it cannot be determined.

A conservator cannot become a fiber expert, an ability which requires long apprenticeship and constant application. In order to develop reliable judgement, however, he must have studied unknown fibers comparing them to known ones during frequent periods of examination under a polarizing microscope, until he feels confident that he can recognize the outstanding morphological characteristics of the major papermaking fibers: linen and cotton derived from rags; flax and other Occidental and Oriental basts; straw; soft- and hardwoods. The dating sequence which we use for the advent of the different kinds of fibers into the papermaker's vat, and the processes of extracting them from the native matrix is that compiled in 1937 by Julius Grant, and more recently restated by B. L. Browning in his 1967 book, The Analysis of Paper. Grant's dating has been of great benefit, but could be refined by further study and accumulation of data. For fiber analysis, we use the methods and teaching of Irving M. Isenberg, a former professor and paper chemist of the Institute of Paper Chemistry, given in his valuable book, Pulp and Paper Microscopy. Together with other needful information, the book has illustrations of magnified fibers ( usually 100�) showing the physical characteristics by which they can be identified. Similar illustrations are also found in such indispensible reference books as Papermaking Fibers by Charles H. Carpenter and fellow authors, and Identification of North American Commercial Pulpwoods by I. Strelis and R. W. Kennedy. These books are used as constant references, as is a collection of permanent slides of known fibers for direct comparison, made with fibers chosen from the TAPPI Fibrary dispensed by the Institute of Paper Chemistry. Even with experience and aided by these references, analysis is not an easy task, because only a few of the many fibers on the test slide may clearly show recognizable features. The slide has to be carefully searched, and sometimes a number of slides from the same specimen has to be examined before a determination can be made. Papermaking processes and the effects both of time and acidity on papers can so break up the fibers that distinguishing factors are lost. Fortunately, the fibers of the paper of wallpaper have been exposed to the action of beaters for a relatively short time because it is The presence or absence of inclusions and foreign matter embedded in the paper's structure is important to record, since, like the history of the use of the various papermaking fibers, they help to establish a probable period for the manufacture of the paper being examined. In handmade wallpapers, especially English and American, many dark spots, specks, wood chips, non-papermaking fibrous cells, etc. are present and can be readily seen on the back surfaces. Some are deliberate additives for fillers, such as scattered shavings of dyed threads predominately in blue or red ( linen, cotton, silk and wool have all been found), or flecks of light brown, bundled bast fibers, possibly jute or manila hemp. Others are the accidental intrusions from the dregs of the vat—wood chips, dirt particles, animal bristles, etc. Better quality handmade papers, such as some French wallpaper which we have inspected, also include dyed shavings, but the purpose for their use was to make a toned paper by a dense scattering of threads all of one color. Early machine-made paper does not have the dyed shavings, or very few of them. Few also are unintended particulated substances. However, an indication of early machine-made paper is the presence of knots and clusters of congested fibers, as well as a pronounced wove pattern of the relatively coarse screening of the machine's belt. The handmade Oriental papers which came to this country in the 19th century ( at least those which we have observed) are composed either of straw fibers, probably rice, or bast fibers, probably paper mulberry. Oriental paper sections are also distinguishable by their size and structure. Usually they are very wide, about 40 inches, and have a plied construction of two or three layers. Another indispensible assist in the analysis of paper fibers is the use of one of the stains which can distinguish by color-change between wood fibers ( soft- and hardwood) and the various cooking processes; rag ( cotton and linen); vascular bundle fibers ( straws and grasses), and bast fibers ( such as flax, jute, hemp and the Japanese papermaking fibers). The iodine stains ( or more specifically the iodine-iodide-metallic salts stains), like the “C” Stain, or the Hertzberg Stain, or the Sutermeister Stain, have proved most useful. In order to avoid the vague and imprecise descriptions of subtle variations of color by words, John H. Graff published a most useful book, A Color Atlas for Fiber Identification. In fact, its charts of the accurately rendered color changes of the various stains are requirements for this kind of study. We use the “C” Stain and since it, like the other stains, has not a long shelf-life, we have a standing order with the Institute of Paper Chemistry to send us a fresh bottle every four months. After the extracted fibers have been spread as separately as possible on the microscope slide using a spot of water as a trap and after the water has dried, a small drop of the stain is placed on the fibers followed by the cover slip. The slide is then ready for examination under the microscope. Incidentally, we find that a magnification of 100x is best, going higher when necessary, and that partial polarization or the defraction patterns of a quarter wave plate often helps to make the physical characteristics of the fibers more distinct. The stain used in conjunction with the researcher's knowledge of the physical characteristics of fibers can be of great benefit. In fact, it is such an aid that analysis is difficult without it. For a few examples: if there is a mixture of different fibers, the stain will give this information Research on analyzing paint of wallpapers by x-ray fluorescence spectrometry is still in its early stages. Mrs. Janice Carlson's initial findings, however, give great promise for the future. Before the machine was used for this purpose, some pigment analysis was done by the lengthy and occasionally unrewarding methods of “wet chemistry,” whereby tiny amounts of paint were taken from the wallpaper and their reactions to prescribed acids, alkalis and other reagents are studied under the microscope. The procedures and reactions are clearly described in the initial 1936 article, “The Stage Microscope in the Routine Examination of Paint Samples”∗ by R. J. Gettens, later amplified by Ms. Joyce Plesters in her 1956 article, “Cross-Sections and Chemical Analyss of Paint Samples.”∗ These procedures are still used for informal determinations or when the spectrometer is unavailable. Whites, blues and greens are of special interest because they have had definite, datable changes since the 18th century.

∗See Biblography The Winterthur spectrometer can detect nondestructively any element whose atomic number is greater than that of chlorine (17). The responses of the machine are both qualitative and quantitative, given out qualitatively in graph-form and quantitatively by a computer printout for each element. Because the tempera paint used on old wallpapers is quite porous and because the structure is layered, the spectrometer “looks through” the layers and reacts to all of them, so that an informed interpretation has to be made by the analyst. The start of research on wallpaper by the spectrometer was begun on a series of papers taken from a late 18th-century Philadelphia house as it was being demolished. The papers, one adhered upon another for eleven layers deep, was presented to Winterthur by their rescuer, Mr. Carl W. Gatter, an amateur historian As far as general research on wallpaper is concerned, we are only at the beginning. A great deal more has to be done; many more papers have to be examined and collated with those of known origin. One day researchers may be willing to pool their information so that a compilation of findings can be established to further our knowledge. Possibly one of the beneficial functions of a National Conservation Center could be to act as a place for gathering and distributing carefully extablished facts about methods and materials. BIBLIOGRAPHYBrowning, B. L.Analysis of Paper. Marcel Dekker, Inc., New York. 1969. Carpenter, Charles H., et al.Papermaking Fibers. State University of Forestry at Syracuse University, Syracuse, New York. 1963. Frangimore, Catherine Lynn. Wallpapers in Historic Preservation. Office of Archeology and Historic Preservation, National Park Service, Washington, D.C.1977∗ ∗A more recent publication by the same auther is a definitive work on the subject; Lynn, Catherine. Wallpaper in America. W. W. Norton & Company, Inc., New York. 1980. GettensR. J. and G. L.Stout. “The Stage Microscope in the Routine Examination of Paintings,” Technical Studies, Vol. IV, No. 4. April 1936 Gettens, R. J. and G. L.Stout. Painting Materials: A Short Encyclopedia. New York, Dover Publications. 1966 Graff, John H.A Color Atlas for Fiber Identification. The Institute of Paper Chemistry, Appleton, Wisconsin. 1940 Harley, R. D.Artists' Pigments c. 1600–1835. American Elsevier Publishing Company, Inc., New York. 1970 Isenberg, Irving H.Pulp and Paper Microscopy. The Institute of Paper Chemistry, Appleton, Wisconsin. 1967 Plesters, Joyce. “Cross-Sections and Chemical Analysis of Paint Samples,” Studies in Conservation, Vol. II, No. 3. April 1956 Strelis, I. and R. W.Kennedy. Identification of North American Commercial Pulpwoods and Pulp Fibers. University of Toronto Press. 1967.

Section Index Section Index |