CONSERVATION OF A MONUMENTAL OUTDOOR BRONZE SCULPTURE: THEODORE ROOSEVELT BY PAUL MANSHIPLynda A. Zycherman, & Nicolas F. Veloz

ABSTRACT—The paper describes a conservation program for a 15-year old monumental bronze sculpture whose state of preservation was satisfactory, but whose visual appearance was poor. A thick coat of pigmented wax was removed with solvent. Graffiti were patinated. The metal was protected from corrosion by the application of benzotriazole and two coats of wax. Examination after one year showed that the bronze was stable; the statue was rewaxed. IN THE LAST 20 YEARS, conservators, scientists and architects have become concerned about the preservation of outdoor bronze sculptures under accelerating atmospheric attack. Naturally, much of their work focussed on older, deteriorated and disfigured works, the ones most obviously in need of aid. Modern outdoor bronze sculptures, which can benefit also from the knowledge gained so far, have not received as much attention. The simple treatment we describe was planned to conserve a relatively new sculpture whose condition was satisfactory, in the face of an increasingly hostile environment. 1 INTRODUCTIONIN 1932, the United States Congress established a nature preserve on an island in the middle of the Potomac River, at Washington, D.C., to commemorate the contributions of President Theodore Roosevelt to the conservation of wildlife and natural resources. Besides its trails, the 88-acre preserve includes a formal memorial to President Roosevelt at the northern end of the island. Designed by Eric Gugler, this memorial consists of an oval plaza, encircled by a water-filled moat spanned by footbridges. A 17-foot bronze sculpture of the 26th President stands at one end of the plaza, in front of a 30-foot granite shaft (Figure 1).1 Roosevelt is depicted in a characteristic speaking pose, his weight slightly forward, his right hand raised for emphasis. The sculpture was commissioned from the American sculptor, Paul Manship (1885–1966), and cast at the Battaglia Art Foundry, Milan, Italy.2 The ensemble was dedicated in 1967 and is maintained by the National Park Service.

The monumental bronze3 is an example of high quality casting and finishing. The large individual sections were cleanly brazed; only neat rows of fine porosity mark the joins. There are 1/4-inch weep holes on each shoulder, one at the top of the head and several at the bottom of the frock coat. The few casting flaws were filled with circular plugs. A National Park Service Memorandum4 on the subject of the “Finish on Theodore Roosevelt Statue” shows that Manship himself selected Bruno Bearzi, an Italian bronze-caster and conservator, to apply a finish to the sculpture. In May, 1966, prior to the dedication ceremonies scheduled for October, 1967, Bearzi arrived in the U.S. to inspect the statue and apply the finish.5 Though the details of his treatment are not given, Bearzi's instructions for maintaining a satisfactory patina and finish are recorded explicitly. He recommended that the

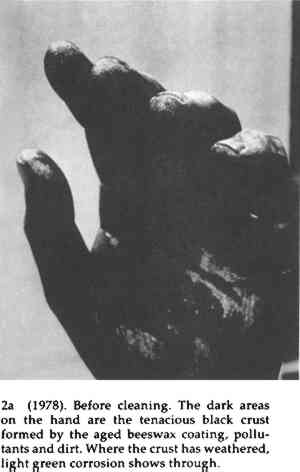

Judging from the available records in the sculpture's file, it seems that Bearzi's maintenance treatment was not carried out semi-annually, as suggested. From time to time the statue was steam-cleaned and brushed with beeswax in turpentine by National Capitol Parks maintenance personnel. In 1974, dark green pigment was added to the wax, presumably to even out the surface color of the bronze which may have become spotty with corrosion. More recently, National Park Service stan applied dark shoe polish on the legs and shoes to camouflage graffiti which had been scratched through the wax coat exposing bright metal. In 1978, funds from the National Park Service became available to resume the maintenance program of Theodore Roosevelt. 2 CONDITIONFOR NEARLY A DECADE and a half, the sculpture has been standing in a site ringed by five major commuter routes carrying 400,000 cars a day and directly under the north approach to the Washington National Airport. Dirt and pollutants had so heavily accumulated in the wax coat that the statue's color was dull black. Details of the hair and jewelry were obscured by the accumulation of wax and dirt and the dull black surface. In contrast to the overall black color, patches of light green corrosion appeared on the head, shoulders, lapels, proper left forearm, tops of both hands and both shoes, the proper right skirt of the frock coat, and the sides of the metal base—areas that are particularly exposed to water and wind-borne particle abrasion (Figure 2a). The brazed join high up at the underside of the frock coat/backs of the thighs was the most corroded area of the sculpture; presumably because of its inaccessibility, this join was less well finished than the others and had not been waxed. Light rain streaking disfigured the broader planes of the bronze. Some corrosion may have been effected by bird droppings, but there is no reason to doubt that most was atmospherically induced. The brazed joins, with the exception of the one under the frock coat already mentioned, were unmarred by an efflorescing core or post-manufacture attack by a corrosive flux. The bronze plugs remained even with the surface both in color and height.

The bronze sculpture's state of preservation was good, but aesthetically, it had changed dramatically since its dedication. The curator (N.V.) decided that the Theodore Roosevelt should be cleaned. 3 TREATMENTTHE TREATMENT we devised7 was designed to improve the sculpture's appearance while complying with the artist's wishes regarding surface treatment (based on the cited memorandum), and to protect and conserve the bronze metal itself. The treatment consisted of the following steps:

3.1 Removal of Surface Accretions and CoatingsTHE COMBINATION of thick, pigmented wax, pollutants and particulates had formed a hard, tenacious black crust on the surface. In an inconspicuous area we tested the solubility of this layer in denatured alcohol, commercial lacquer thinner, VM & P naphtha, gum turpentine and Varsol, a petroleum distillate, BP 150�–170�C. The latter two were quite effective on the wax and dirt but slightly less so on the shoe polish. We decided to emulsify the dirt and wax in a solution of water/gum turpentine (1:1) with 2–5% Igepal, CO-630, a non-ionic wetting agent, and 1% Aerosol-OT, an emulsifier. After some experimentation with scrub brushes, cotton diapers and nylon scrub pads, we found that the most successful method was to lay a soaked diaper compress on the surface, wait 15 minutes for the wax to be emulsified, and then wipe the emulsified wax off with a second saturated diaper. Stiff brushes and nylon pads were essential for cleaning out details such as hair and folds.8 The emulsified wax runoff made the bronze base, the granite pedestal, and the plaza slick and dangerous to stand on. Although periodic hosing with water alleviated the problem somewhat, we decided to eliminate the emulsion treatment in favor of straight gum turpentine applied with diapers and scrub pads. Every inch of the bronze was soaked, wiped and scrubbed repeatedly (Figure 3).

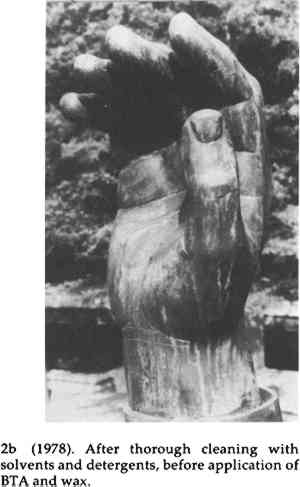

After the first solvent strip, we washed the sculpture, granite pedestal and plaza with a 5–10% aqueous solution of a commercial detergent and grease cutter9 to help remove remaining traces of wax and emulsified run-off. For the second solvent strip the diapers soaked with Varsol remained white, proving that the sculpture was nearly clean, except for the underside of the frock coat and the upper backs of the legs, below the unwaxed corroded join. In these protected and nearly inaccessible areas the wax was still soft and pliable; perversely, because of its easy solubility it smeared, and was even more difficult to remove than the tenacious black crust on the exterior. After a second scrub with detergent followed by a thorough rinse and a third Varsol strip the sculpture was judged free of surface accretions and wax. A final degreasing with white cloths saturated in denatured alcohol completed this phase of the treatment. The appearance of the Theodore Roosevelt at this point was vastly different from that before cleaning (Figure 2b). In protected areas where the wax layer appeared to have been intact prior to cleaning, the bronze was a golden brown color with a light haze of green corrosion in places, instead of a uniform, dull black. The broad surfaces, which now appeared satiny from a distance, showed a pattern of fine concentric lines at closer inspection, most probably the traces of mechanical finishing and polishing. Where the wax had weathered and eroded, the green corrosion was thicker and opaque, with a distinct pattern of brush marks, especially on the shoulders. This could be the result of differential rates of corrosion under an unevenly applied wax coat. Details of the hair and jewelry were once more visible. The depth and extent of the graffiti—swastikas, initials, etc.—became clearer.

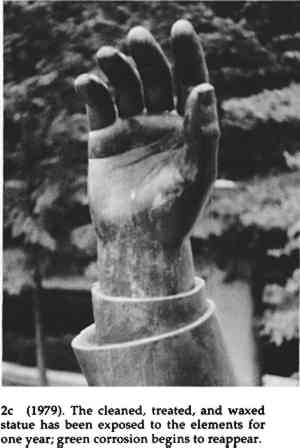

3.2 Patination of Graffiti15% POTASSIUM SULFIDE in water, repeatedly swabbed on cold, was the first solution we tried to color the graffiti, but after rinsing and rubbing with a cotton diaper the resultant brown color was weak. A commercial bronze patination solution10 based on selenious acid gave better results. The desired degree of brown was obtained after a few passes with a swab. The solution was feathered out to visually blend the graffiti with the surrounding metal. The area was rinsed with water and buffed with a diaper. 3.3 Protection Against CorrosionIN OUR OPINION the statue's satisfactory state of preservation was certainly due to its relatively recent and excellent casting. In addition, for this particular bronze in its present location, the protective nature of the wax coating was significant. Therefore, Manship's wishes regarding surface treatment were still a feasible method of preservation for the bronze. However, since we were unsure of semi-annual or even annual maintenance, additional protection against corrosion seemed warranted. We chose benzotriazole (BTA) as the corrosion inhibitor, to be applied directly to the clean bronze surface. We considered, and decided against, using Incralac,11 a well-known lacquer containing BTA, chiefly because of the difficulties we faced with its recommended spray application. The sculpture itself, as well as the setting, constituted the main obstacles to spraying an even lacquer coat. The 30-foot granite shaft stands less than three feet behind the figure, making it impossible to get the manlift cage in between. We were effectively impeded from spray lacquering the back of the figure directly, as well as adequately masking the granite shaft from the over spray. It would have been equally impossible to spray lacquer under the hard-to-get-at folds of the frock coat which, in places, stood only inches away from the legs. Another drawback to using Incralac on the Theodore Roosevelt was that any lacquer coat would be quickly broken by the public climbing on the accessible parts of the statue, and overly frequent touch-ups would be necessary. An aqueous solution of BTA had the advantages of easier application and upkeep while still performing well as a corrosion inhibitor. BTA12 was dissolved in 75:25 warm water/alcohol to make a 3% solution by weight. The alcohol was intended to increase the penetration of the solution by decreasing surface tension. As the solution dried on the surface excess BTA precipitated as white crystals, which were easily hosed off with water. The visual effect of the BTA treatment on the bronze was to make it slightly darker and more uniform in color. As a final protection, we applied two thin coats of a homemade wax paste, formulated for durability and spreadability.13 The wax was applied in the afternoon, when the bronze was warm enough to absorb as much as possible. Following Bearzi's recommended procedure, but using cloths instead of brushes, we smeared the wax in circular motions on the large, smooth areas. In the details, a shoe polish dauber gave better results. We then buffed with clean cloths and soft brushes. This finishing wax treatment darkened the bronze a bit more and diminished the contrast between the heavy green corrosion and the metal. The haze of thin corrosion on the broad surfaces disappeared. The final color was similar to the water-wetted clean bronze (Figure 2d).

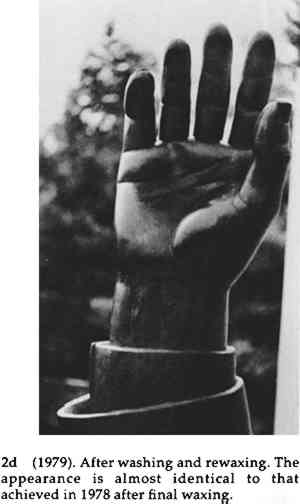

4 ONE YEAR LATERIN JULY 1979 the Theodore Roosevelt was re-examined. Its visual appearance and state of preservation were satisfactory, despite the small changes which had occurred. The new formula wax paste had withstood the elements quite well; it was still uniform and water resistant. Of course, the sculpture was again covered with surface dirt. Some of the old patches of corrosion had reappeared, due to rain streaking (Figure 2c).

To remove the dirt we washed the statue with a 5% solution of pure soap in water. Much of the soot washed off easily and the water beaded up and readily ran off the well-preserved wax coat. Two thin coats of wax paste were applied over the old wax. This time, instead of buffing after both coats were applied, we buffed each coat individually. The first waxing and immediate buffing removed remaining grime from the surface. The second coat seemed to camouflage the green corrosion patches, but after solvent evaporation they reappeared, albeit to a lesser extent (Figures 1 and 2d). 5 FUTURE UPKEEPSHOULD NO NEW CONSERVATION problems develop, the National Park Service plans to wash and wax the surface of the sculpture annually or bi-annually, and quinquennially to strip the wax completely, reapply a corrosion inhibitor and rewax. Assuming that the environmental conditions remain substantially unchanged, we believe that this regular maintenance will keep the Theodore Roosevelt in fine shape for the foreseeable future. 6 COSTTHE COST OF THE TREATMENT (manpower plus materials) was approximately the same as that of the previous steam-cleaning/beeswax treatment. The time involved was: NOTES1. James M. Goode. The Outdoor Sculpture of Washington, D.C., A Comprehensive Historical Guide. (Washington, D.C., 1974), catalogue number E-6, pp. 187, 188, describes the monument and its history in detail. 2. On the sculpture's bronze base the foundry's name is abbreviated as Fond. Artis/Battaglia C./Milano, Italy. 3. From head to toe the statue is 17 feet high, but the upraised right arm and the 6-foot granite plinth make the actual height closer to 27 feet. The 30-foot granite shaft is a mere three feet behind the figure. 4. National Park Service Memorandum #D52-2618, February 7, 1967, from Supervisor of Contract Administration, Ralph R. Ross, to Superintendent of Prince William Forest Park and George Washington Memorial Parkway (unnamed), on the subject of the “Finish on Theodore Roosevelt Statue.”The first paragraph reads, “During May 1966, Mr. Bruno Bearzi, a resident of Italy selected by the sculptor and consultant architect(s), inspected and applied the present finish on the statue.” The memorandum continues with Bearzi's instructions for maintaining a satisfactory patina and finish. This paragraph is quoted in full in the text of this article. 5. The sculpture had arrived in the U.S. approximately one and a half years earlier and was set on site. As a protection against vandals, the statue was completely crated except for the upraised right hand. The Washington Post, October 28, 1967, A1 and B1. 6. See note 4. 7. Steven Tatti, Sculpture Conservator, Hirshhorn Museum and Sculpture Garden, Washington, D.C. helped to plan the treatment. Ms. Stephanie Faul and Mr. Victor Bernhard assisted in the work. 8. The operations were carried out from a locally rented JLG-27-foot manlift. The cage bumpers were padded with rags to protect the sculpture and the granite shaft from accidental scraping.Most of the chemicals and tools used can be obtained from a paint and hardware store. Igepal CO-630 (non-ionic wetting agent) and Aerosol OT (emulsifier) can be bought from TALAS, 140 Fifth Avenue, New York, N.Y. 10011, U.S.A.Diaper rags were purchased from a diaper rental service. 9. Spic and Span; the label gives its composition as sodium sesquicarbonate, sodium tri-polyphosphate, tri-sodium phosphate, plus small quantities of other cleaning materials and an anionic surfactant. 10. Antique Black M24 Swab-on Finish is an instant-acting cold chemical swab-on or touch-up finish for use on brass, bronze copper and muntz metal. Used at room temperature it will produce colors from light brown to brown and to black. A product of Birchwood Casey Division, Fuller Laboratories, Inc., 7900 Fuller Road, Eden Prairie, Minnesota 55343, U.S.A. 11. Incralac, a solvent-type acrylic resin, (Acryloid-B-44, Rohm & Haas) plus benzotriazole, is available from Stan-Chem Inc., East Berlin, Connecticut 06023 U.S.A. 12. We used Cobratec 99, a commercial grade of benzotriazole, manufactured by Sherwin Williams Chemical Company, 1310 Expressway Drive So., Toledo, Ohio 43608, U.S.A. Product information and application suggestions can be found in Cobratec, Sherwin Williams Technical Bulletin #531. Benzotriazole, which is toxic if taken internally, may also be carcinogenic. Protective masks and gloves should be worn when applying BTA. See: W. A. Oddy. “Toxicity of Benzotriazole.” Studies in Conservation. XIX (1974): 188–189. 13. The wax paste was provided by Steven Tatti. The composition is: dissolved in mineral spirits to a soft, creamy consistency. Bareco waxes are products of Bareco Division, Petrolite Corporation, 6910 East 14th St., P.O. Drawer K, Tulsa, Oklahoma 74115, U.S.A. Cosmolloid 80H is obtainable at TALAS.

Section Index Section Index |