STORAGE CONTAINERIZATION: ARCHAEOLOGICAL TEXTILE COLLECTIONSDennis Piechota

ABSTRACT—Improved methods are needed for the low-cost stabilization of the storage environment and for increased accessibility and safe use of stored archeological textile collections. Substantial microenvironmental control and protection from shock and handling can be provided by individual storage containers. The author describes a container designed for the Peruvian archaeological textile collection of the Peabody Museum, Harvard University. Its costs, construction, assets and restrictions are described, based upon a pilot project where forty textiles were containerized. 1 INTRODUCTION1.1 The Need for Improved Storage MethodsTHE SAFE STORAGE of museum collections continues to be an area for development in conservation. Conservators should, for instance, explore methods for the low-cost stabilization of the storage environment, as many museums cannot afford even the maintenance costs of a climate control system, let alone the initial investment. If 1.2 Mass Treatment: ContainerizationOUR TESTS at the Peabody Museum suggest that storage containerization as a mass treatment strategy may be particularly suited to the needs of anthropological collections. The simple process of placing specimens in thoughtfully designed containers can:

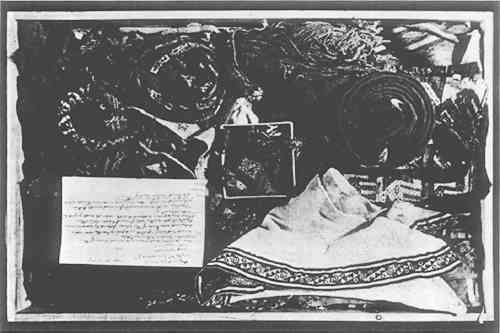

Certainly this is not a new idea. It is an extension of traditional fine arts containerization: mats, frames and bases given to prints, paintings and mounted sculpture. With anthropological collections, however, there may be an additional reasoning for containerizing. If these collections are to remain an unimpeachable scientific resource, then their chemical integrity should remain as unadulterated by preservative treatments as possible. They should be maintained pristine. In fine arts 2 A TRIAL APPLICATION2.1 The CollectionTHE PEABODY MUSEUM of Harvard University owns one of the largest and most extensive archaeological collections of Peruvian textiles in the United States. Approximately 2850 specimens ranging in age from Pre-ceramic Period VI (B.C. 2500–1800) to the late Horizon (1476–1534 A.D.) document 4,000 years of technology. The physical condition of these specimens varies greatly, so that ultimate in-lab treatments will also vary. Since there is a demand to study them now, however, most on-going damage is caused by their retrieval from their haphazard and crowded storage. They are folded, rolled and piled into wooden trays that were designed for archaeological lithics and ceramics (Fig. 1).

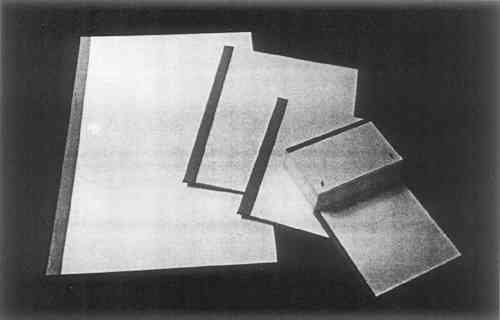

In 1977 the author with the assistance of a museum volunteer, Wendy Shah, began a project to develop a storage container for the collection that would alleviate the poor conditions while not requiring massive time and expense devoted to needlework. Inspired by a matted folder decades old we designed a modular set of containers that could accomodate 90% of the collection based upon a 10% random sample (Fig. 2).

2.2 Container Construction

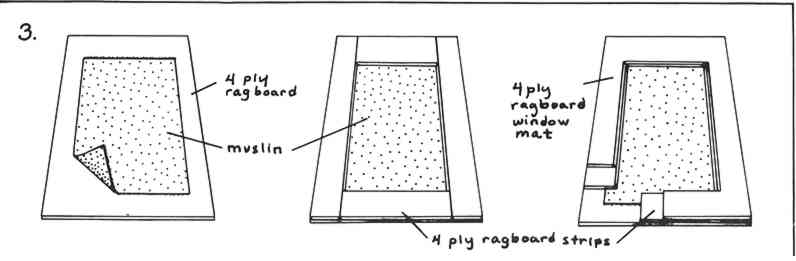

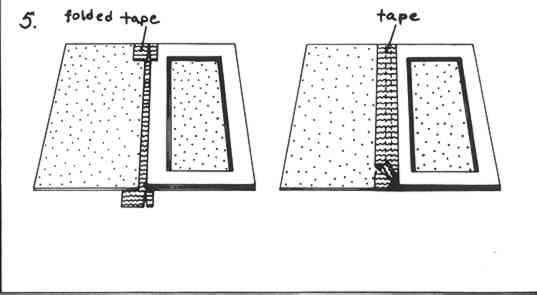

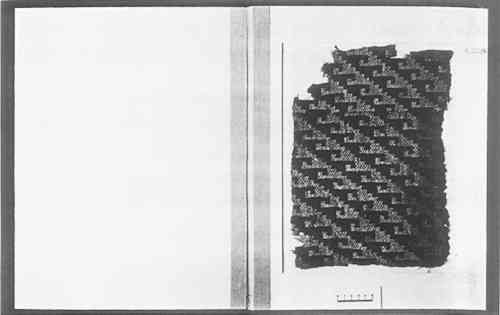

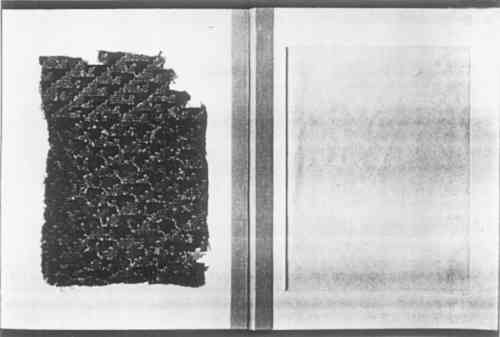

FIGURES 3 THROUGH 5 show the construction steps of the basic container. It has a backboard, mat and lid of acid-free ragboard. The backboard and lid are 4-ply while the mat is built up to the thickness of the textile fragment. The interior surfaces of the backboard and lid are faced with muslin. A textile fragment is held within this container between the two muslin surfaces. The mat surrounds the textile in its third dimension keeping excess pressure from it. In this unit stitching is optional. The textile is laterally immobilized by friction-contact with both muslin surfaces. This allows for complete viewing of both the obverse and reverse surfaces of the textile.

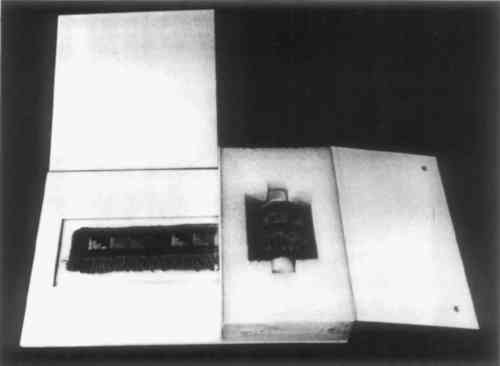

There are two variations on this basic unit. Long, narrow weavings are partially rolled and housed in Ethafoam�4 blocks that are adhered to the basic container. (Fig. 8) This enables more efficient use of storage space while providing easy access to at least one design repeat. The largest container size, capable of holding textiles up to 60 cm. by 90 cm. in dimension, requires additional rigidity. To provide this, a 3 1/6;″ thick laminated foam sheeting material, Fome Cor� board, is used as the backboard for containers of this size.

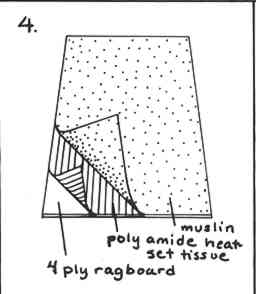

2.2.1 Materials of ConstructionTHE MATERIALS OF CONSTRUCTION were selected for inherent stability and permanence with the exception of Fome Cor� board.5 Since its paper facing is acid, its internal surface should be covered with Mylar�6 or aluminum foil to stop vapor migration to the textile. The mat, lid and backboard are of acid-free, buffered ragboard. The muslin is washed and unbleached. The hinge is composed of starch-sized linen book-cloth. The adhesives used are Jade 403�7 and a poly-amide heat-set tissue8 commonly used in document conservation. The Jade 403�, a PVA emulsion, adheres all components of the backboard together including the muslin which is adhered only under the mat away from contact with the textile fragment. This adhesive is also used to adhere the Ethafoam blocks to the basic units when constructing containers for long and narrow textiles. For a strong bond the Ethafoam surface needs to be washed with a degreasing solvent, roughened and clamped. This adhesive is also used in hinging the lid to its backboard with the linen bookcloth. The other adhesive, the poly-amide heat-set tissue, is used solely to bond the muslin to the lid. Ethafoam was selected for its presumed chemical inertness as expanded polyethylene and for its ease of cutting. 2.2.2 Costs of the ContainersTHE AVERAGE COST per container is low. Materials alone cost approximately $3.35 in late 1977. In-house assembly time requires 45 minutes to one hour per container. All operations susceptible to machine execution, such as ragboard cutting and heat sealing, can be contracted; their cost is included in the materials cost. 2.3 Container TestingNO STORAGE CONTAINER DESIGN, even one as traditional in concept as this, should be applied without preliminary small-sample testing. Therefore, forty prototype containers were made to test their safety and useability under realistic conditions. During six months of display to visiting student groups and study or simulated study by a variety of users the containers were indeed found safe and practical when the users were first instructed in the proper method of handling.9 As has been shown elsewhere,10, 11 the enclosure of an object in a small airspace or micro-climate with hygroscopic materials can cushion against sudden external humidity fluctuations. To test the humidity buffering efficiency of this textile container design a simple test was devised. Twelve containers were acclimated to an Not until three days had passed did the containers' humidity begin to rise and it was not until the seventh day, making comparisons every twenty-four hours, that all containers had equilibrated to the humidity of the chamber. It should be noted that the top two containers in the stack equilibrated more quickly, especially the topmost, which has the greatest surface area exposed for absorption. These required only four to five days to reach the humidity of the chamber. Assuming that the moisture content of the textiles alone would equilibrate 3 CONCLUSIONS3.1 BenefitsIN SUM THE CONTAINERS provide these benefits:

3.2 ApplicabilityTHE STORAGE CONTAINER designed for archaeological textile collections offers one method of slowing the rate of deterioration of massive collections without necessitating chemically alternating treatments and without exhorbitant expense. It is an initial step that will allow time to carry out more intensive treatments at an unhurried pace. Concurrently, collection use can proceed without collection damage. For all collections where pristineness of chemical composition is valued for research purposes, containerization recommends itself as a purely mechanical method of preservation. ACKNOWLEDGEMENTSI AM INDEBTED to Wendy Shah for her devoted work in assembling the containers, to Jane Drake Piechota for her criticism and to Marjorie Cohn for her criticism and for reading this paper at Fort Worth in June, 1978.

REFERENCESThomson, Gary, “Stabilization of RH in Exhibition Cases: Hygrometric Half-time,” Studies in Conservation, Vol. 22, 2, May, 1977. Mori, John L., “Revising Our Concepts of Museum Research,” Curator, Vol. 14, no. 3, 1972. Ibid. Ethafoam� is an expanded polyethylene foam product of Dow Chemical Corp., 20 William Rd., Wellesley, MA. Available from local foam products companies. Fome Cor� board is a product of Monsanto Company. It is composed of an extruded polystyrene foam core that has been laminated between two sheets of linear board. The products marketed for artists' use are available in three thicknesses: ⅛″, 3 1/6;″, and �″. The liner used on the ⅛″ and �″ product is 42-pound natural Kraft while the 3 1/6;″ product has a 50-pound white claycoated liner. The pH of the white liner is 5 to 7. The thickness determines structural stiffness, the thicker boards possessing greater stiffness and higher flexural strength. For additional information, contact Mr. William Bruton, Monsanto Company, E3NF, 800 North Lindberg Boulevard, St. Louis, Missouri, 63166. Mylar� is the Du Pont trade name for polyethylene terephthalate. Available from TALAS, Division of Technical Library Service, 104 Fifth Ave., NY, NY, 10011. Also available from TALAS. Occasionally a textile fragment was found to adhere too strongly to one or the other muslin surfaces of its container. This problem was overcome by burnishing the muslin with a hard-surfaced tool so as to compress its nap and thereby decrease its “tooth’ or friction. Stolow, Nathan, “Fundamental Design for Humidity Sensitive Museum Collections,” Museum News (Technical Supplement), Vol. 44, no. 11, February, 1966. Stolow, Nathan, “Microclimate: A Localized Solution,” Museum News, Vol. 56, no. 2, November-December, 1977. Humidicator� paper is a product of the Micro Essential Laboratory Inc., Brooklyn, NY, 11210 and is available through TALAS. At low humidity the paper appears blue and as the humidity is increased it changes color moving gradually to red.

Section Index Section Index |