TREATMENT OF A FLOOD-DAMAGED OIL PAINTING ON A SOLID SUPPORTDAVID C. GOIST

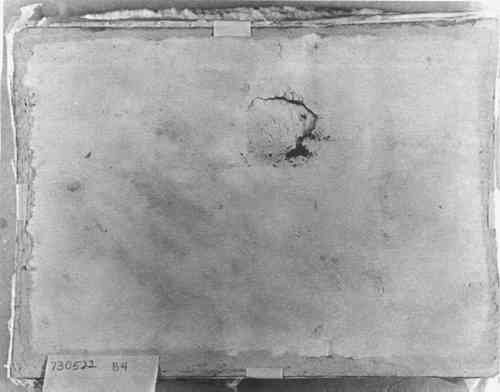

3 TREATMENTThe mud was removed by gently rolling cotton swabs dampened with water plus a wetting agent across the surface. Although a solvent-type natural resin varnish had never been applied, the ample proportion of oil medium in the paint layer allowed relatively easy removal of the mud with all rolling stopped short of the various areas of damage. Removal of the major portion of mud permitted examination of the paint film and thin white oil layer serving as the ground. Shrinkage, warpage and the central rupture cracks Reduction of the distortion in the ruptured area was the first requisite in treatment. That section was faced with two protective layers of shin tenjujo paper adhered with a cornstarch paste. As each paper was applied and dried, it was coated with n-butyl methacrylate resin dissolved in petroleum benzine in an attempt to gain visibility, flexibility and strength to the faced section of damage. The painting was turned face down in the wooden rack in which it had arrived and the fiberboard support was delicately cut away with a scalpel from the reverse of the securely faced ruptured section. The exposed cracked reverse of paint and ground was coated with polyvinyl acetate (AYAC/AYAA, 50:50) in toluene. The addition of thermoplastic films to both sides of the expanded area enabled a response to minimal heat from an infrared lamp, and gradual manual pressure successfully reduced the bulge to conform to the surrounding support. With no disturbance of the facing over the now-flattened rupture, the entire paint surface A negative impression of the paint texture and warp of the support was made with polyurethane foam2 isolated from the facing tissue by very thin aluminum foil. To insure that no undue pressure would be placed on the still vulnerable section, a watch glass was placed over the rupture during the foaming process. The set foam provided a firm, very light weight support during the removal of the remaining fiberboard from the reverse of the painting. Because the reverse bore legends of identification, it was faced in turn and every attempt made to remove its uppermost layers intact. Due to the thinness and brittleness of the support, a one-piece removal was not feasible. The back layer was cut in pieces whenever necessary to avoid possible risk to the paint and ground. At the conclusion of the treatment the portion of the support bearing the writing was patched and backed and returned to the museum. During the slow and cautious removal of the support it became apparent that the artist had occasionally emphasized his design by scratching into his wet paint and thin ground exposing the fiberboard. Such scratch lines were found behind the knees and under the arm of the reclining figure. Their presence increased the fragility of the paint and thin ground. The polyvinyl acetate mixture (AYAC/AYAA, 50:50) in toluene used to reinforce the cracks adjoining the rupture was again employed to strengthen these intentional breaks. Once the rigid support was entirely removed, as shown in Figure 2, the faced paint and

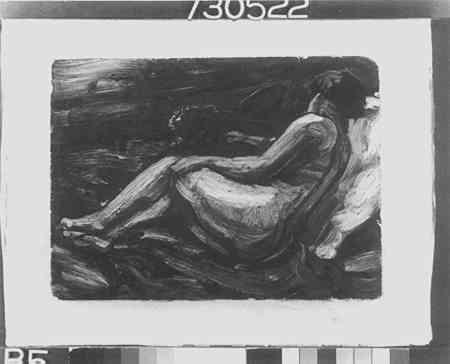

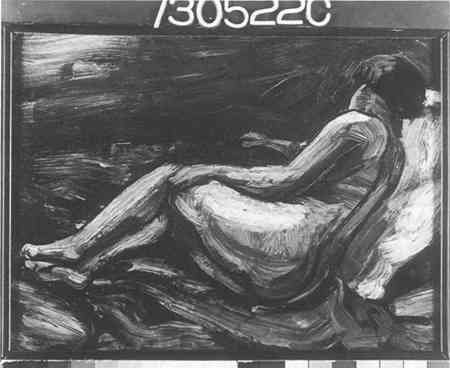

It was presumed that traditional techniques for transfer would introduce gesso cracks or impressions of canvas weave foreign to the special quality of this painting, particularly where the support is visible through the scratched “emphasis lines.” In order to avoid such impressions and maintain a comparable tone in the lines, the following method was employed. A handmade Japanese paper similar in color to the original support was selected. Two sheets each slightly larger than the size of the painting were sized with wheat paste and stretched on a drying board. Rohm and Haas Rhoplex AC-34 acrylic emulsion was considered as a sizing but bypassed due to its tendency to make the paper transparent and lose the desired tone. When the wheat paste and paper were dry, each sheet was coated evenly with the “Hot Melt” adhesive devised by Bernard Rabin.3 With the painting still faced, the reverse was rinsed first with detergent in water then with acetone to provide a clean bonding surface. A thin and even brush coat of “Hot Melt” adhesive was applied to it. After an appropriate lapse of time to permit the solvent to evaporate from the adhesive, each sheet of prepared Japanese paper was attached individually to the reverse on the vacuum hot table. The two-stage attachment proceeded in a manner similar to a standard lining operation under a rubber membrane with the painting face up on the “Hot Melt” side of the Japanese paper. The paper was isolated from the hot table surface each time by mylar film. The result was the faced paint and ground attached to a double thickness of flexible Japanese paper. To assure the consolidation and add rigidity to the new lamination, a 4-ply 100% cotton fiberboard was attached with wax-resin (Multiwax W445/Piccolyte S-85, 2:1) adhesive to the reverse of the double layer of Japanese paper. The 100% cotton fiberboard was first entirely infused with wax-resin adhesive. The attachment was conducted on the vacuum hot table in the same manner as with the previous sheets of Japanese paper. Once the lamination was secured to the fiberboard, the facing was removed with solvents as shown in Figure 3. Small deposits of mud around the edges of the breaks and formerly cupped paint came away with the removal of the facing adhesives.

A balsa core panel was selected to further provide rigidity and security. A birch wood veneer (3/16″ thick) was chosen to sandwich a core of end-grain balsa wood blocks (�″ thick) with four redwood strips serving as a collar. Two veneer sheets cut to the dimensions of the painting were sized with shellac. The end-grain balsa blocks fitted within the redwood collar were glued to one of the veneer sheets with polyvinyl acetate emulsion adhesive. To the other veneer sheet the laminated painting was attached with wax-resin adhesive by means of the vacuum hot table in the manner previously stated. Finally the picturebearing veneer sheet was glued with polyvinyl acetate emulsion to the balsa block surface of the first veneer sheet. The painting received an isolating spray application of Permanent Pigments, Inc. Soluvar brand acrylic resin varnish diluted in petroleum benzine. The small losses of paint were filled with a gelatin and whiting putty. Inpainting was completed in pigments ground in n-butyl methacrylate resin. A “dry” spray of Rohm and Haas Acryloid B-72 resin dissolved in xylene was applied to the finished painting to reduce the gloss and to provide a harder, thus more dust resistant, surface than Soluvar varnish. The painting after treatment is shown in Figure 4.

|