Conservation of Nineteenth-Century Tracing Paper: A Quick Practical Approach

by Susan PageTracing Paper

Who has tracing paper?

Many institutions house collections of architectural and engineering drawings on tracing paper. Tracing paper, or transparent paper as it is also called, has been used for a wide variety of designs in archives, museums and libraries. Historically, tracing paper was used for work plans by engineers, architects, and builders. Artists were also drawn to tracing paper because of its translucency and relatively low cost. the condition of most nineteenth-century translucent paper ranges from dry and brittle to fractured into tiny splinters. Some tracings have been repaired with various mending tapes. Others contain a wide array of adhesives. Most are too fragile to handle or serve without support.

What is tracing paper?

Tracing paper has excellent optical transmission properties. Most nineteenth-century translucent paper is thin, machine-made wove paper and is made from either 100% rag or chemical wood pulp. in the past, hand-made laid paper was also transparentized by adding drying oils and resins. But once machine-made roll paper became was available, it became the paper of choice. Pulp for tracing paper was extensively beaten in a Hollander-type beater. the fibers become flat, like ribbons, and fiber-to-fiber interstices are closed. This process produces highly fibrillated fibers that result in hundreds of tiny ends. These ends bond together physically to interlace and form a thin tightly packed web. the pulp was further compacted and compressed. the sheet produced was virtually free of interstices, which cause internal light scattering surfaces. Because light falling on tracing paper does not bounce back nor scatter, it passes directly through the sheet and it appears transparent, After the sheet was formed, additional transparency was achieved by impregnating the paper with oils and resins. When exposed to air, these drying compounds produced translucent paper. Typical transparentizing mediums are Canada basalm, dammar, and linseed oil.

Tracing paper offers an attractive hard, smooth working surface. It is also thin and transparent and therefore, easy to reproduce. Thus it is an ideal material for working drawings.

Why do we know so much about it already?

There has been an upsurge of information, both conservation treatment and analysis about tracings. We are fortunate to have these resources available.

When was it first used?

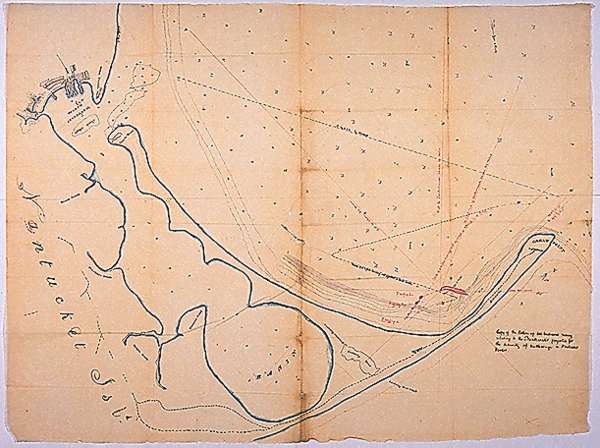

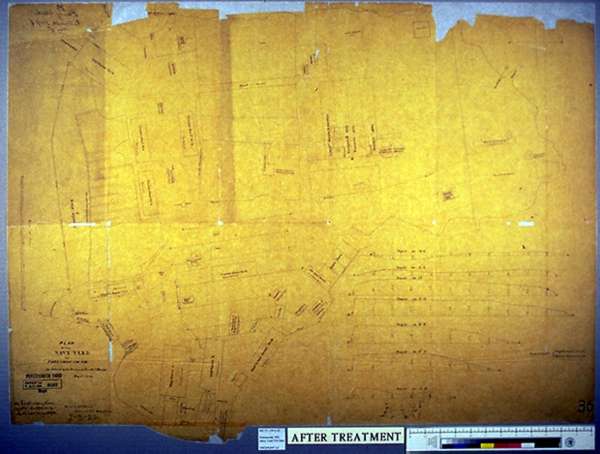

Fig. 1. National Archives and Records Administration map of Nantucket, 1828, after treatment.

Precise dates are difficult to pin down but most experts agree that mass produced tracing paper was available soon after machine-made paper was produced. Dard Hunter cites 1862 as the date of earliest manufacture of tracing paper as a definite commodity for professional use, but the National Archives has a map on beaten tracing paper that dates from the 1820's, see Fig 1.

Where do we go from here?

With this as background, let's sail on to the conservation of some of nineteenth-century ships plans.

Conservation

Project Description

The Cartographic and Architectural Branch at the National Archives and Records Administration in Washington, DC, presented the conservation lab with a group of 30 intrinsically valuable, historically important ships plans on resin impregnated tracing paper in January 1996. These records posed challenges for preservation. Most plans were drawn in stable media: black carbon, red, and blue ink. Most of the plans had been extensively repaired with a variety of tapes. Most were larger than 24 inches by 40 inches in size. in the past many ingenious attempts were devised to protect and preserve these lovely drawings. Before coming into NARA custody, well intentioned records custodians had done what they could to provide support both beneath the fragile tracings and above to protect the vulnerable information and drawings.

The ships plans were divided into two groups. Each batch has unique conservation issues. Some of the tracings had been previously attached to a secondary support; a sheet of ground wood paper which was then attached to rigid fiber board. the drawing and supports were covered with a protective sheet of cellulose acetate film which was secured to the back of the board with tape. the second and smaller group of folded plans came to the lab housed in standard permalife folders.

Treatment decisions

When tracing paper is made, the pulp is heavily beaten. As a result of pulping, the short fibered tracing paper reacts vigorously to water or polar solvents. in the presence of water and polar solvents, otherwise flat paper becomes unstable. Lining would provide the extra support these fragile plans required. in addition, these particular papers are very thin. They differ in this way from other drawings on transparent paper. Historically these thin sheets were used to copy information from original drawings for reproduction to, for example, blue print paper. Mending such thin paper could disfigure the tracings as well as require considerable treatment time. the lining adhesive should be compatible with cellulosic materials and reversible.

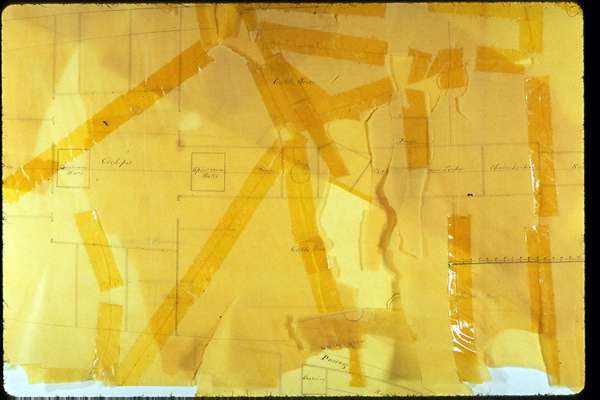

Fig. 2. Fragile transparent plan on tracing paper with pressure sensitive tape.

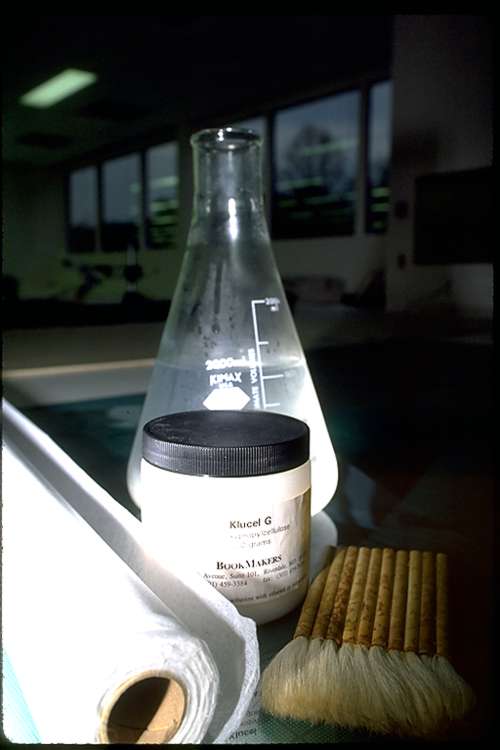

Klucel G was selected as the adhesive because of its flexibility, compatibility, and it dissolves in either water or a variety of organic solvents, for example, ethanol, acetone, and toluene.1 Dissolved in deionized water, the cellulose ether was reactivated with organic solvents. the goal was to find a solvent which when lightly misted over the lining paper would allow the paper to remain flat, reactivate the Klucel G adhesive to permit a light bond between the lining and highly impregnated paper, without disturbing the inherent resins and oils in the tracing paper, e.g. without changing the paper from transparent to opaque.

Fig. 3. Materials for lining: 2% Klucel G in water and Japanese machine-made roll paper.

Therefore, several solvents and solvent combinations were tried. Recent investigations on the effect of solvents on some properties of tracing papers have been conducted on contemporary paper. However, the conservation treatment described here, however, involves older historic tracing paper which react differently. in addition, exposure to solvents is limited to light application in areas where there is pressure sensitive tape residue. Linings are attached by lightly misting the Klucel G to reactivate the adhesive. Ethanol alone readily remoistens the lining adhesive but is too polar and caused tracing paper distortion. Acetone alone did not cause the paper to react and because of its quick drying time, reduced the possibility of moving the resins in the tracing paper. Toluene remoistened the adhesive but, because of its toxicity, was ruled out. As previously discussed, the oxidized, resin impregnated paper is reluctant to absorb any liquid. This proclivity includes the solvent remoistening and activating the lining adhesive. Therefore, 50:50 ethanol and acetone was selected to reactivate the Klucel G on the Japanese roll paper lining. This solvent combination reactivated the lining adhesive to allow contact but did not deeply penetrate the resin impregnated tracing paper. As a result, the lining is lightly attached. Therefore, this lining is mechanically reversible. in theory, the mechanical reversibility eliminates the need for and dangers inherent in large solvent baths or damaging techniques to achieve lining reversibility.

Removal from secondary supports

Cellulose acetate coverings were mechanically removed from the drawing and support board.

Some time during the past, the tracings had been drummed to acidic paper with a proteinaceous adhesive. in order to separate the tracing paper from the ground wood paper, I tried various techniques including Gore-Tex and wet blotters placed on the reverse, water applied directly to the verso, and water applied to the recto of the ground wood lining paper. I chose the latter method to remove the drummed tracings because the old adhesive softened before the highly reactive hygroscopic paper wet out. I applied water with a Japanese calligraphy brush. the adhesive readily softened and the tracing was lifted free from its paper backing with a thin Teflon coated metal spatula. Because the tracing paper is impregnated with oxidized resin and oil, the paper is initially reluctant to absorb other substances, such as water. Thus, the paper surface permits quick local aqueous treatment of its surface. Internally, the highly beaten, short fibered paper is dimensionally reactive to water. Therefore, longer exposures to moisture renders abundant planar distortion. Judicious, light-handed application of water can be useful.

Tape Removal

In addition to protective supports and coverings, most of these drawings had been repaired with various tapes during the past.

Non-pressure-sensitive tapes: Glassine and linen tape

Glassine and linen tape was removed from the verso by applying a small amount of warm water on top of the tape to soften the adhesive. Much of the adhesive was removed when the carrier was lifted off. Residue was removed with moist cotton swabs and the paper blotted dry.

Pressure sensitive tape: Cellulose acetate tape

Previously applied strips of pressure sensitive cellulose acetate tape carrier were brittle and desiccated. Removal was simplified because they either fell off or were gently lifted with a thin metal spatula.

Adhesive residue removal

Conservation treatment included reducing adhesive tape residue. This is a challenging conservation procedure on tracing papers. the adhesive residue is soluble in the same solvents which solubilize the transparentizing resin impregnating the tracing paper. There is consensus among most conservators in favor of retaining the original transparentizing compounds. Testing done to the adhesive after the carrier was removed revealed that a solvent or solvent combination could reduce the adhesive mass without blanching or stripping the resin from the tracing paper. However, some of the drawings were covered with rather large amounts of repair tape. Because any manipulation of these brittle papers harbors the potential to cause further damage and loss, the adhesive mass on some tracings could not be treated. in these few cases risk of damage or loss during even careful handling was too great to permit safe adhesive reduction. Whenever possible, however, removing adhesive residue mass reduces visual distraction and allows the plans to be read more easily.

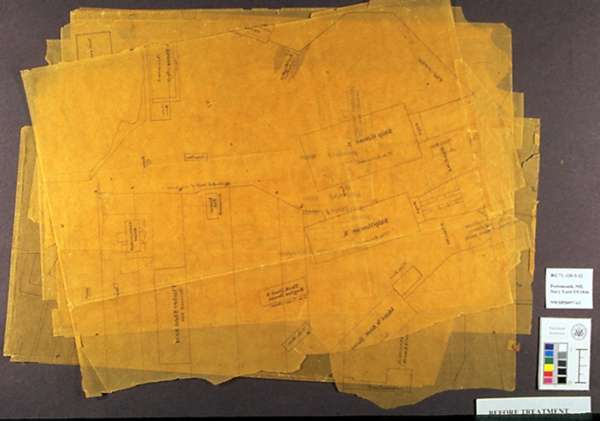

Fig. 4. Tracing before treatment (Treatment carried out by Amy Krzminski, intern, State University College, Buffalo).

Several solvents were tested and tetrohydrofuran and the more user friendly mixture-- 40% acetone, 30% ethyl acetate, and 30% heptane were used. .2 This solvent substantially reduced the adhesive residue mass without stripping the resin from the impregnated tracing paper or altering any of the media. A shadow of adhesive tape residue remains apparent on most of the plans. the solvent treated areas were not flushed with water due to the paper's reactivity to moisture. All adhesive removal was conducted on a vacuum suction table.

Fig. 5. Tracing after conservation.

Humidification and Flattening

Several ships plans had been folded and bundled together. At first glance, it was difficult to know if the bundle contained one or several drawings. These ships plans were separated into single sheets and passively humidified. the chamber was fitted out with wet blotter and the object supported from below with acrylic "egg crate" diffusion panels. the plans were gently flattened between very thick blotters. Most plans responded to a single humidification and flattening procedure, some required additional humidification and flattening time.

Preparation of lining paper

Lining paper was prepared by brushing a 2% solution of Klucel G onto large sheets of uncoated Mylar. After the first application of adhesive dried, two more layers were applied and air dried. While the fourth and last application of Klucel G was wet, a sheet of thin Japanese machine-made roll paper (Paper Nao, RK No. 17) was statically attached to a Mylar support, brushed onto the adhesive, and smoothed with a lining brush. the Mylar supporting the paper was removed from the surface. the lining paper was air dried and stored on Mylar. When ready for use, the Mylar was removed from the lining paper. Do not pull the lining paper off the Mylar because the paper will distort.

caption. Brushing down lining.

Realigning pieces

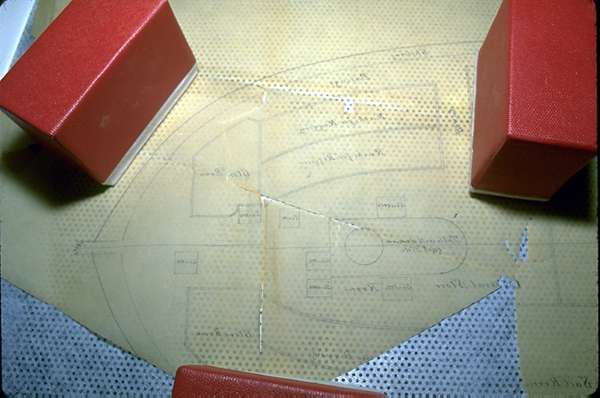

Fig. 6. Realigned rather than mended pieces before lining.

Rather than mend the numerous and lengthy tears and fill losses, all plans were lined, thus conserving countless conservation treatment hours. This is an appropriate method for mass treatment of a large collection. the drawings were placed face down on a thin sheet of Hollitex on the bed of the vacuum suction table. Tears were realigned without vacuum pressure and held in place with weights cushioned with paper-maker's felts. Light vacuum pressure held the pieces in place. Then the weights were removed.

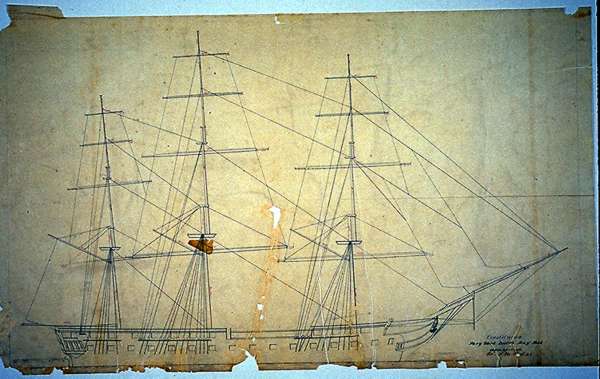

Fig. 8. Tracing of USS Constitution, NARA, 1849, after conservation treatment.

Solvent activated lining

Once the tracing and related pieces were in place, vacuum pressure was increased. Lining paper was placed on the verso of the tracing, smoothed by hand to increase contact, and covered with a sheet of thin Hollytex. Because the tracings are not perfectly flat, smoothing during the lining process was helpful to increase contact between lining and tracing. for very long ships plans, two sheets of lining paper were butt joined together during solvent activated lining.

With the vacuum set at maximum pressure, approximately 30 psi, a 50:50% solution of alcohol (ethanol) and acetone was sprayed over the surface with a Dahlia atomizer. the lining was brushed out with a Japanese lining brush to increase contact.

Success test

Fig. 9. USS Constitution, New York Harbor.

Contact between the tracing paper and lining is intentionally light. To test adhesion, first visually inspect contact. If the lining is only partially attached, lightly remisted with the solvent mixture until the desired degree of contact is achieved.

Adhering small pieces

While still under pressure on the vacuum suction table, the lined drawing was dried for 10 minutes. Both sheets of Hollytex were removed and excess lining tissue cut away. Any detached small pieces were adhered in place. A drop of water moistened the lining adhesive; the fragment dropped in, and the added fragment dried under light weight.

Color compensation

If color compensation is desired, light shading with oil pastels (Rembrandt) can be used to tone the lining paper to visually compensate for loss.

Encapsulation Caveat

This light handed approach to conserving these fragile and vulnerable drawings requires encapsulation as a housing system for storage and research use. Careful handling is a must in preparing tracings for exhibition.

The ships plans were encapsulated for stoeage in 4 mil polyester film (Mylar). A sheet of alkaline lining paper was inserted in the encapsulation to counteract acidity of the paper. This insert can also improve visibility and contrast in viewing images on transparent paper.

Conclusion

When to use this practical time sensitive technique?

Large collections of tracings with consistent problems

In conclusion, I believe this simple conservation method responds positively to criteria for treating transparent papers. This practical approach was developed to conserve a collection of lovely nineteenth-century utilitarian pen and ink drawings on resin impregnated paper. Conservation treatment includes adhesive reduction from resin impregnated paper and aligning and lining as an alternative to tedious and possibly visually disfiguring mending. Although this approach could be used for treating unique works of art on paper, it is probably best adapted to large collections containing numerous tracings with consistent treatment problems.

Notes

1. While the dry powder of high molecular weight grades of Klucel darken upon thermal aging, Klucel G applied as a film does not. " the results after aging at 90 ° C, illustrated in Figures 6.4, 6.5, and 6.6, indicate that, when applied as thin films, most of the coatings exhibited little or no change. . . From the results, it can be seen that most films of the cellulose derivatives were more resistant to color change than a sheet of filter paper." Feller, R.L., Evaluation of Cellulose Ethers for Conservation, the Getty Institute, 1990, p. 68.

2. Nicholson, C., A Less Toxic Solvent Mixture for Tape Stain Removal, Washington Conservation Guild Newsletter, January, 1991.

Susan PageSenior conservator

The National Archives and Records Administration

Publication History

Received: Fall 1997

Paper delivered at the Book and Paper specialty group session, AIC 25th Annual Meeting, June, 1997, San Diego, California.

Papers for the specialty group session are selected by committee, based on abstracts and there has been no further peer review. Papers are received by the compiler in the Fall following the meeting and the author is welcome to make revisions, minor or major.