Observations on the Use of Bookkeeper® Deacidification Spray for the Treatment of Individual Objects

by Sarah D. Stauderman, Irene Brückle, and Judith J. BischoffAbstract

Bookkeeper® Deacidification Spray (magnesium oxide in a non-reactive carrier with a surfactant) has recently been made commercially available for non-aqueous deacidification of paper artifacts. In a series of experiments, the spray was applied by spray and brush to different papers and tested in a variety of ways to determine its effectiveness for the deacidification of small or individual artifacts. Atomic absorption spectroscopy, scanning electron microscopy, colorimetry and pH measurements were employed (before and after artificial aging at 90°C, 50% RH) to determine the amount and nature of the magnesium oxide deposit, and to assess the appearance and permanence of the papers studied. For comparison, some papers were treated with a different non-aqueous deacidification spray (Wei T'oTM). Bookkeeper® Deacidification Spray was shown to deposit a significant amount of magnesium, penetrate the paper unevenly, leave a precipitate, and did not protect the paper from color changes during artificial aging.

Introduction

Since the nineteenth century, it has been known that reducing or removing acids can significantly prolong the life of paper. Not all paper-based materials can undergo an aqueous treatment for acid reduction, however, due to fragile media or paper constituents. In the past decades, developments and improvements have been made to several non-aqueous deacidification methods intended for library and archive collections.1, 2, 3 Efforts to find a practical non-aqueous deacidificant have focused primarily on mass-deacidification methods. These methods have employed elaborate machinery to deposit deacidifying agents into groups of books and documents. The smaller-scale use of the deacidificants in some cases is impractical or dangerous, and has been pursued as a by-product of the large-scale deacidification. Of the methods formulated for small-scale use, perhaps most notable in the United States is Wei T'oTM (carbonated magnesium methoxide) by Richard Smith. Another individual-use solution available is Archival Aids (carbonated magnesium methoxide ethoxide), primarily in use in Europe and Canada.2, 3

Bookkeeper®

In 1993, Preservation Technologies, Inc. (PTI), introduced the Bookkeeper process to the United States' Library of Congress as a solution to the need for large-scale deacidification. The process, which uses special equipment to deposit the deacidificant into books, is a suspension of colloidal magnesium oxide in an inert carrier with a surfactant (perfluorohexane and perfluoropolyoxyetheralkanoic acid, respectively). This mechanized process was evaluated by a team of conservators, scientists and preservationists, which resulted in the publication of the report An Evaluation of the Bookkeeper® Mass Deacidification Process.4 The report concluded that "the PTI Bookkeeper® deacidification technology meets the criteria set by the Library of Congress for a process which shows potential for meeting their specifications."5

More recently, the Bookkeeper® formula has been made available in spray bottles for use on individual objects. Its formulation is different in that the inert carrier is a less expensive version of the carrier used in the mass-process.5 It is considered environmentally safe, and contains non-toxic components which do not pose a health hazard in the laboratory.7

Application

One type of application of Bookkeeper® involves spraying one or both sides of a paper sheet with the solution, using the hand-held spray bottle in which it is sold. The manufacturer suggests a spray distance of six inches. The nozzle on the spray bottle is adjustable, but the solution can drip from the nozzle unless the bottle is held in an upright position. Thus, the artifact must be supported semi-vertically to spray without dripping. (The bottle is also available in an aerosol-type spray; however, the experiments in this report were performed with the pump-spray bottle).

Chemistry

The following chemistry is proposed to occur when the Bookkeeper® solution is sprayed on a sheet of paper.8 The carrier evaporates, leaving behind the fine particles of magnesium oxide and the surfactant in the paper. Magnesium oxide reacts with water from the surrounding atmosphere or in the paper to form magnesium hydroxide, a known deacidificant (Equation 1).

MgO + H2O -------> Mg(OH)2 (1)

Magnesium hydroxide reacts with acids in the paper to form magnesium salts. For example, the alkaline magnesium hydroxide can react with acids such as sulfuric acids to form magnesium sulfate salt (Equation 2).

Mg(OH)2 + H2SO4 ------> MgSO4 + 2H2O (2)

Research has not shown what happens to the water-soluble magnesium salts which remain in the paper,9 and what possible side-effects the presence of the surfactant may have on the long-term stability and properties of paper and media.10

Experimental

The experimental methods used here were based on research carried out in the early 1970s by Santucci and others which resulted in the article "An Evaluation of Some Non-Aqueous Deacidification Methods for Paper Documents."11 Three different non-aqueous treatments had been employed: barium hydroxide, magnesium acetate, and magnesium methoxide (an early version of Wei T'oTM). Immersion, brush and spray application methods had been compared for their ability to deacidify.

In the research presented here, old and modern papers were treated with Bookkeeper® Deacidification Spray and exposed to different humidity levels and accelerated aging. The following points were investigated:

- amount of Bookkeeper® deposited with different application methods

- evaluation of application methods to find out which one is best suited to deposit the recommended alkaline reserve concentration (3.6 mg of magnesium per 1 gram of paper)12

- effect of different application methods on the measured pH change of the treated paper

- effect of the treatment on the appearance of the paper and media

The paper samples selected for treatment are as follows:

A machine-made wood-pulp paper from an American book from 189

B handmade book paper from 1832 containing flax and cotton

C mixed-pulp (bast and cotton fibers) mid 19th-century printing paper

D contemporary newsprint from artists' sketch block

E Whatman® filter paper (#2 qualitative)

F contemporary Fabbriano artists' paper, mould-made, colored brown

- various 19th century prints: chromolithographs, hand-colored etchings, wood-cuts

Atomic Absorption Spectroscopy

To determine the amount of magnesium present in treated paper, atomic absorption (AA) spectroscopy using a Jarrell-Ash spectrophotometer was performed following TAPPI test methods.13

Paper samples used for analysis: A, D, E.

Treatment of paper samples:

- untreated control

- Bookkeeper®, sprayed "lightly" on one side only (following manufacturer's instructions)

- Bookkeeper®, sprayed "heavily" on one side only (subjective to the conservator)

- Bookkeeper®, brushed on one side only

- Bookkeeper®, air-brushed on one side only

- Wei T'oTM, brushed on one side only

- Magnesium bicarbonate(0.225 ppm, pH 9.0), immersion wash for 20 minutes

Scanning Electron Microscopy

The penetration characteristic of Bookkeeper® was explored by scanning electron microscopy (SEM)/Energy Dispersive x-ray analysis (EDX) with a Hitachi S-800 SEM. The front and back of paper samples were analyzed.

Paper sample used for analysis: B (thickness .007").

Treatment of paper samples:

- untreated Control

- sprayed with Bookkeeper® on one side only and stored in a 30% relative humidity chamber for 5 1/2 weeks, ambient temperature

- sprayed with Bookkeeper® on one side only stored in an 80% relative humidity chamber for 5 1/2 weeks, ambient temperature, and then aged for seven days at 90°C, 50% RH in a Blue M Humid-FlowTM Temperature/Humidity Chamber

Microscopic analysis

It cannot be expected that the image area of objects are always properly avoided during treatment. To acquire a better understanding of how the application of Bookkeeper effects printed media, several expendable 19th-century prints were sprayed with Bookkeeper in the image area to observe the resulting effect. The appearance of the prints was recorded by photographing the treated areas before and after treatment with a Wild (Heerbrugg) Microscope at 6x to 40x magnification.

Colorimetric Measurements

In order to evaluate the color of the paper samples before and after treatment, colorimetry was performed with a Minolta Colorimeter in the L*a*b* color space, which measures whiteness (L*), redness/greenness (a*), and yellowness/blueness (b*). Three types of paper were treated using different application methods. Then, they were divided into three groups, each of which was stored under different RH conditions, and finally half of these were artificially aged.

Paper samples used for analysis: A, B, C.

Treatment of paper samples:

- untreated control

- brush with Bookkeeper® on one side only

- spray with Bookkeeper® on one side only

- brush with Wei T'oTM on one side only

- Magnesium hydroxide (0.225 ppm, pH 9.0), immersion wash for 30 minutes

Each of the above treated papers was divided into three different humid storage environment groups for 5 1/2 weeks: 20-30% RH, 45-65% RH and 70-80% RH (each at room temperature 22�3°C). Finally, half of each of the stored samples was placed in a BLUE M Humid-FlowTM Temperature/Humidity Chamber for seven days at 90°C, 50% RH.

pH Measurements

Measurements were taken of the same samples in the colorimetry group (Colorimetric measurements, above) with a Corning pH meter 125 (Beckman dual-head electrodes 40498) standardized with standard buffer solutions of pH 10.0, pH 7.0 and pH 4.0. Deionized water (pH 7.0) was placed drop-wise on the surface of the paper and the electrodes placed in the water until the meter balanced to a set point. The Bookkeeper® literature describes that complete conversion to magnesium hydroxide takes place within 28 days, thus the time period for the storage (5 1/2 weeks) allowed for neutralization (as reflected in pH measurements) to occur.

Results And Discussion

Amount Of Magnesium Deposited: Atomic Absorption Spectroscopy

Figure 1a. Results of atomic absorption

spectroscopy on paper A (1892 wood-pulp paper).

Deposit of magnesium on 1892 paper after different

treatments (optimal alkaline reserve is 3.6 mg

Mg++/g paper). Each paper sample is one book page

(approximately 2.0 grams) and treated on one side,

except for the washed sample.

* The untreated control registered a magnesium content of 3.57 mg; however, it should be noted that this paper was extremely brittle and discolored, and had a pH of approximately 5.5. Whatever its magnesium content, it was most likely not in the form of the desired alkaline reserve (magnesium hydroxide), but rather some other compound with little buffering reaction to acids present in the paper.

Figure 1b. Results of atomic absorption

spectroscopy on paper D (contemporary newsprint).

Deposit of magnesium on contemporary newsprint

after different treatments. Each paper sample is

approximately 1.5 grams, and treated on one side

only except for the washed sample.

* As with the 1892 paper, this paper registered a high magnesium content (2.24 mg) before treatment. Again, the magnesium present is most likely not in the form of the desired alkaline reserve (magnesium hydroxide), but rather some other compound with little buffering reaction to acids present in the paper.

Figure 1c. Results of atomic absorption

spectroscopy on paper E (Whatman® filter

paper). Deposit of magnesium on Whatman®

filter paper after different treatments. Each

paper sample is approximately 1.0 grams, and

treated on one side only except for the washed

sample.

Figures 1a-c show the amount of magnesium deposited. The average amount of magnesium was five to eight times more than considered necessary for alkaline reserve (3.6 mg Mg+2)12, with amounts deposited varying considerably from application to application. For instance, "light" sprays of Bookkeeper on paper A deposited from 7.53 to 19.80 mg Mg+2/g paper. The "heavy" sprays also ranged from 16.67 to 26.73 mg Mg+2/g paper. Obviously, it is difficult, if not impossible, to apply Bookkeeper® consistently with a hand-held sprayer.

While a high concentration of magnesium compounds may insure that there is a high alkaline reserve, possible negative effects cannot be ruled out. Banik et al. showed that some papers treated with a magnesium-based deacidificant have an increased uptake of air pollutants, and a resulting poor mechanical performance in comparison to untreated paper.14

Furthermore, there are several possible reactions occurring once magnesium oxide or other magnesium-based deacidification material has been deposited in the paper.15 (Atomic absorption spectroscopy only determines the amount of magnesium present, not the species.) This includes the formation of basic magnesium carbonates and the creation of localized alkaline sites of variable and/or high pH which could promote alkaline-catalyzed chain scission of the cellulose molecule, or increase the rate of oxidation of lignin or hemi-cellulose in wood-pulp papers.

Penetration of Bookkeeper®: Scanning Electron Microscopy

Figure 2a. EDX Spectra of paper B (untreated

control).

Figure 2b. SEM photomicrograph of paper B.

1,500x magnification of 1832 linen/rag paper.

The untreated control of paper B showed no peak in the SEM/EDX spectrum for magnesium [Figure 2a and 2b].

SEM/EDX analysis of the paper treated with Bookkeeper® on one side only, showed that the deacidificant did not penetrate through the paper to the other side, regardless of its humid storage conditions after treatment.

Figure 3a. EDX Spectra of paper B, sample 2,

treated side. This paper had been stored in a 30%

relative humidity chamber for five and a half

weeks. It has a strong magnesium peak.

Figure 3b. SEM photomicrograph of paper B,

sample 2, treated side (1,500x). The small

particles here contain magnesium.

Figure 4a. EDX Spectra of paper B, sample 2,

untreated side. There is no significant peak for

magnesium.

Figure 4b. SEM photomicrograph of paper B,

sample 2, untreated side (1,500x). There are no

particles as seen on the treated side of paper

B.

Figure 5a. EDX Spectra of paper B, sample 3,

treated side. This paper had been stored in an 80%

humidity chamber for over five weeks and then

placed in an accelerated aging chamber for seven

days at 90° C, 50% RH. There is a strong

magnesium peak.

Figure 5b. SEM photomicrograph of paper B,

sample 3, treated side (1,500x). Magnesium

containing particles are apparent on the treated

side of the paper.

The treated side of sample 2 of paper B showed particles of a magnesium-containing compound and a large magnesium peak on the spectrum [Figure 3a and 3b]; the back of this paper, however, did not show any particles, nor did the SEM/EDX detect any magnesium [Figure 4a and 4b].

Figure 6a. EDX Spectra of paper B, sample 3,

untreated side. There is no significant magnesium

peak.

Figure 6b. SEM photomicrograph of paper B,

sample 3, untreated side (1,500x). The particles

seen here were analyzed by EDX to be silicon.

The third sample of paper B showed a similar trend: the treated side showed the magnesium-containing particles and a corresponding high magnesium peak [Figure 5a and 5b]. Furthermore, no magnesium was detected on the untreated side of Paper C [Figure 6a and 6b].

While the particles containing magnesium coated the treated sides of the paper, no magnesium was detected on the untreated sides. There is a difficulty in determining if a two-sided application would be beneficial. The magnesium material only penetrates partially into the paper. In this case, depending on the thickness and porosity of the paper, spraying on both sides could set up a sandwich effect, with an untreated layer in the middle of the paper.

Appearance: Microscopic Examination

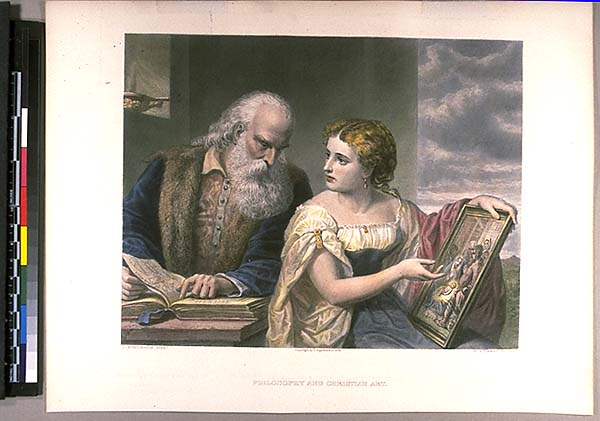

Figure 7a. Overall of a hand-colored lithograph

before treatment with Bookkeeper®.

All papers treated with Bookkeeper® by spray or brush showed a chalky white precipitate, even at low magnification [Figures 7a-7c]. This may be not be acceptable on some types of historic artifacts, and certainly not with objects where the integrity of an image should be preserved.

Of the application methods tested (Bookkeeper spray, airbrush and brush) the most uniform and pleasing application was with the airbrush, though the precipitate was still apparent.16 The airbrush nozzle was set to deliver a fine mist, and airbrush apparatus was easily rinsed with water after use.

Aging: Colorimetry

Colorimetry data of paper C are shown in Figures 8 - 11.

Figure 8. L*a*b* values for paper C (unaged mid 19th-century paper) after treatment.

Figure 9. L*a*b* values for paper C after aging.

Figure 8 shows the L*a*b* values of samples after spraying with Bookkeeper®. The treated side of the paper whitens slightly due to the presence of the white magnesium compounds, and there is also a slight shift in a* and b* values, decreasing redness and yellowness. Figure 9 shows the L*a*b* values after aging. There is an overall lowering of whiteness, and an increase in redness. In comparison, the washed papers discolored less.

Figure 10. Overall change in L* values (brightness) between unaged and aged samples of paper C after treatment. There is an overall greater decrease in brightness of the treated sample.

Figure 11. Overall changes in a* and b* after accelerated aging of paper C after treatment. There is an increase in redness (a*) and yellowness (b*) over the control and the washed samples.

The change which occurred over aging (delta E) shows that the sprayed sample had the greatest decrease in brightness compared to the control and washed samples [Figure 10]. The untreated back of the sample also seems to be affected. The treated sample also shows the greatest increase in yellowness and redness (Delta a* and b*) [Figure 11]. It seems that the presence of Bookkeeper® on these samples did not inhibit formation of discoloration during accelerated aging. It should be noted that the Wei T'o-treated sample also discolored to the same degree as Bookkeeper®.

This result is not inconsistent with other magnesium-based treatments described in the literature. In general, magnesium-based deacidificants have been shown to have a tendency to yellow upon humid accelerated aging over their untreated and calcium-treated counterparts.17

Alkaline Reserve: pH Readings

| Before Aging | After Aging | |

|---|---|---|

| Untreated Control | 5.97 | 4.46 |

| Sprayed Side (Front) | 7.77 | 6.56 |

| Unsprayed Side (Back) | 5.28 | 5.48 |

| Brushed Side (Front) | 6.79 | 6.45 |

| Unbrushed Side (Back) | 5.40 | 5.72 |

| Before Aging | After Aging | |

|---|---|---|

| Untreated Control | 6.45 | 5.89 |

| Sprayed Side (Front) | 8.41 | 8.00 |

| Unsprayed Side (Back) | 6.59 | 7.20 |

| Brushed Side (Front) | 9.49 | 8.60 |

| Unbrushed Side (Back) | 9.01 | 8.43 |

| Before Aging | After Aging | |

|---|---|---|

| Untreated Control | 6.60 | 6.25 |

| Sprayed Side (Front) | 8.05 | 7.65 |

| Unsprayed Side (Back) | 6.96 | 6.58 |

| Brushed Side (Front) | 7.74 | 6.36 |

| Unbrushed Side (Back) | 5.60 | 5.57 |

Figure 12. A comparison of pH readings for three types of paper after treatment with Bookkeeper®. The treated papers were sprayed or brushed on one side only. Aging took place in an accelerated aging chamber at 90°C, 50% RH for seven days. In general, the treated side of the papers increased by at least one point, while the untreated side sometimes increased by only half a point.

The pH levels increased by over one unit on the treated side, but rarely more than half a unit on the untreated side [Figure 12]. In fact the pH of the treated sides of some papers were greater than the American National Standards Institute standard of pH 7.5 for new permanent papers.18 After aging

(7 days at 90°C, 50% RH) the pH of the treated papers, front and back, was generally higher than the untreated control.

During pH measurements it was noted that the Bookkeeper®-treated sides of papers absorbed water faster, and the subsequent application of water produced very discolored tide-lines in comparison to the untreated sides of papers. There are several possible explanations for this phenomenon. The alkali may function similar to paper fillers, increasing paper wettability; or, the gelatin surface size may be affected. It also seems likely that the fluoro-surfactant, while relatively non-reactive towards the cellulose, lowers surface tension of the water and facilitates penetration. The staining may be a result of a combination of factors: an alkaline environment which aids in moving discoloration and the surfactant increasing "washing" efficiency.

Conclusion

This work focused on the working characteristics and purported benefit of Bookkeeper® used in individual spray application. Papers treated with Bookkeeper® showed observable color changes after aging, and some changes in the paper character. An excess of magnesium oxide is easily deposited with hand-held sprayers, and an even deposition is difficult to achieve. The magnesium-containing particles leave a noticeable whitish haze on the paper that can be visually distracting. In one-sided spray application, the pH of the paper can be expected to be higher on the treated side than on the untreated side. Color shifts during artificial aging indicate that at least some types of paper treated with Bookkeeper® experience a whiteness reduction greater than that occurring in untreated papers. This may not be the only magnesium-based non-aqueous deacidificant that produces such an effect.

Additional (long-term) experiments will have to be conducted before further conclusions can be drawn on the effects of Bookkeeper® (and other non-aqueous) deacidification agents in the treatment of individual artifacts. For now, however, it remains to be emphasized that the spray application of Bookkeeper® still poses unresolved questions that inspire caution.

Suggestions For Further Research

Research could be conducted on the effect of the fluoro-surfactant, on the interaction of Bookkeeper® with inks and other media. The effect of the magnesium salt residues could be studied in long-term aging experiments. In the meantime, more specific guidelines should be made available on the consistent and proper application of Bookkeeper®. Ways to remove excess magnesium oxide, other than dry brushing, should also be explored.

Acknowledgments

This research was undertaken at the Art Conservation Department at Buffalo State College, in Spring 1996. The authors wish to thank the faculty, especially Dr. F. Christopher Tahk for suggestions in directing the research, and Dr. Daniel Meloon (Chemistry Department) for providing the atomic absorption instrument. Dr. Peter Bush and Mike Miesckowski at the School of Dentistry SUNY Buffalo provided the SEM/EDX services. Students helped perform subjective tests on the paper samples. The Allery, Toronto, Ontario graciously donated prints to the department for experimentation.

References

1. Hon, David N.S. 1989 "Critical Evaluation of Mass Deacidification Process for Book Preservation" in Historic Textile and Paper Materials II. [Rec'd. 2/22/89] 13-33. This article contains a concise review of the history of acid papers and early attempts to use non-aqueous deacidificants to arrest paper deterioration.

2. Pidek, J. 1986. "Chronological Chart of Deacidification Methods." New Directions in Paper Conservation, Conference Notes, IPC Conference 14-18 April 1986. London: Institute of Paper Conservation. D73.

3. Lienardy, A. 1991. "A Bibliographical Survey of Mass Deacidification Methods." Restaurator 12. 75-103.

4. Buchanan, S., W. Bennett, M. Domach, S. Melnick, C. Tancin, P. Whitmore. 1994. An Evaluation of the Bookkeeper Mass Deacidification Process: Technical Evaluation Team Report for the Preservation Directorate, Library of Congress. Washington, D.C.: Preservation Directorate, Library of Congress.

6. Private communication, James E. Burd, PTI, Inc. President (June 1996).

7. MSDS from PTI (February 5, 1993) states that the Bookkeeper Deacidification Dispersion is "Non-Hazardous" with respect to the Perfluoro compounds, and the magnesium oxide. The surfactant ("proprietary") complies with EPA & TSCA Regulations.

8. Buchanan, S. et.al. Appendix E.

9. Conversation with George Wheeler, April 19, 1996.

10. Buchanan, S., et.al. 13-21.

11. Santucci, L., Ventura, G. and M. Zappala-Plossi. 1973-4. "An Evaluation of Some Non-Aqueous Deacidification Methods for Paper Documents" in Etudes Concernant la Restauration d'Archives, De Livres et de Manuscrits. Brussels, Belgium: Archives et Bibliotheques de Belgique. 131-154. This research from the Institute for the Study of the Book, Rome, was an early exploration into the effect of non-aqueous deacidification when applied to individual objects. The commentary noted that there was additional criteria besides proof of deacidification which should be sought by archivists in applying non-aqueous solutions to paper objects, namely the post-treatment appearance should be acceptable and vary as little as possible from pre-treatment.

12. Buchanan, S., et al. 5. This is based on the protocol of 30 milliequivalents per 100 grams of paper listed in the evaluation document.

13. TAPPI Test Methods 1994-1995. 1994. Atlanta, Georgia: Tappi Press. The following tests were used: T266 om-94 (Determination of sodium, calcium, copper, iron, and manganese in pulp and paper by atomic absorption spectroscopy), T211 (Ash in wood, pulp, paper and paperboard: combustion at 525° C), T550 om-93 (Determination of equilibrium moisture in pulp, paper and paperboard for chemical analysis).

14. Banik, G., W. Sobotka, A. Vendl, and S. Norzsicska. 1993. "Effects of Atmospheric Pollutants on Deacidified Modern Papers" in Preprints, ICOM Committee for Conservation 10th Triennial Meeting, Washington, DC, USA, 22-27 August, 1993. Volume II. Paris: ICOM. 435-441.

15. Hey, M. 1979. "The Washing and Aqueous Deacidification of Paper." The Paper Conservator. Volume 4. 66-80. Though focusing on aqueous treatments for paper, this article contains interesting information about magnesium-based deacidification and some of its effects.

16. The hand-sprayed and brushed samples very clearly showed the path of the spray or brush on the surface of the paper, and drops of the deacidificant were obvious.

17. Kolar, J. and G. Novak. 1996. "Effect of Various Deacidification Solutions on the Stability of Cellulose Pulps." Restaurator 17. 25-31.

18. American National Standard for Permanence of Paper for Publications and Documents in Libraries and Archives: ANSI/NISO Z39.48-1992. 1993. National Information Standards Series.. New Brunswick, New Jersey: Transaction Publishers.

Suppliers

Bookkeeper

Preservation Technologies, Inc.

111 Thomson Park Drive

Cranberry Twp., PA 16066

Paper Conservation Intern

Preservation Office, Firestone Library

Princeton University

Irene Brückle

Assistant Professor of Paper Conservation

State University College at Buffalo

Judith J. Bischoff

Assistant Professor of Conservation Science

State University College at Buffalo

Publication History

Received: Fall 1996

Paper delivered at the Book and Paper specialty group session, AIC 24th Annual Meeting, June 10-16, 1996, Norfolk Virginia.

Papers for the specialty group session are selected by committee, based on abstracts and there has been no further peer review. Papers are received by the compiler in the Fall following the meeting and the author is welcome to make revisions, minor or major.