A Study of the Quality of Japanese Papers Used in Conservation

by Sue Beauman Murphy and Siegfried RempelSue Beauman Murphy is Assistant Paper Conservator in the conservation department of the Harry Ransom Humanities Research Center, The University of Texas, Austin, Texas.

Siegfried Rempel, formerly Conservation Scientist in Photography at the Harry Ransom Humanities Research Center when this study was conducted, is now with the Centre Canadien d'Architecture.

The first phase of a project to determine the quality of Japanese papers used in conservation treatments has recently been completed. Over a year ago four major U.S. distributors of Japanese papers were contacted: Aiko's Art Materials Import Incorporated, Andrews/Nelson/Whitehead, Light Impressions Corporation, and University Products Incorporated. The companies sent samples of paper they considered conservation quality Japanese papers which were currently available. From those samples, forty-nine papers were selected for examination. Papers were selected on the basis of descriptions provided by the distributors which promoted them as conservation products. In addition, twenty-one handmade and fourteen machine-made papers distributed through a Tokyo-based company, Paper Nao, were added to bring the total number tested to eighty-four. The first phase involved two analyses: pH cold water extraction and fiber content.

Testing: pH Extraction

Three cold water extraction pH tests were run on each paper according to TAPPI test T-509 om-83.1 The results of those three tests were then averaged to obtain the final figures in Table 1.

The pH measurements indicate that all but a single paper fall in the neutral or alkaline range, depending on the addition of alkalis during preparation and cooking or from additions of calcium carbonate as a buffer. It is reasonable to assume, however, that those papers containing lignified debris or untreated wood fibers will not remain stable, probably increasing in acidity over time.

Testing: Fiber Analysis

Examination of the fiber quality was carried out according to TAPPI standard T-401 om-82. Specimens were torn into tiny pieces from different areas of the paper sample, placed in a small beaker, covered with dilute solutions of an alkali2 followed by an acid3, heating and rinsing well after each chemical treatment. After the water was drained off, the pieces of paper were rolled into a ball between the fingers and placed in a test tube. Distilled water was added, and the contents were shaken until the fibers were thoroughly dispersed. The fibers were transferred to microscope slides using a disposable pipette. The slides were dried on a warming tray, stained with Graff's C-stain, and viewed through a Leitz triocular compound microscope using transmitted light.

Fibers were identified on the basis of their morphological characteristics and associated cellular matter, as well as their color when stained. When necessary, measurements were taken of fiber widths and associated cellular elements to aid in identification. When more than one fiber type was identified on a slide, a count was taken and the fiber ratios were tabulated according to weight factors of those specific fiber groups.

With the benefit of a camera which attaches to the third ocular, the paper fibers were photographed. All photomicrographs were taken with Kodak Ektachrome Tungsten 160 ASA slide film at a magnification of 250x. The results of the fiber analysis can be seen in Table 2.

Analysis of Data

Permanence and durability of a paper are of course directly related to the processing and treatment the fibers receive during the pulping process.4 In Japanese papermaking, the Japanese fibers are cooked using one of at least four alkalis , which helps, to a degree, to get rid of the acids produced by lignin. However, with the use of Western wood pulp in Japanese papermaking, a new variable has been added to the quality of these papers. Naturally, the addition of any untreated wood products to a paper, even in small amounts, will affect its permanence and, in consequence, its durability. Of the papers tested, a total of four samples (3.4%) contained untreated wood fiber.

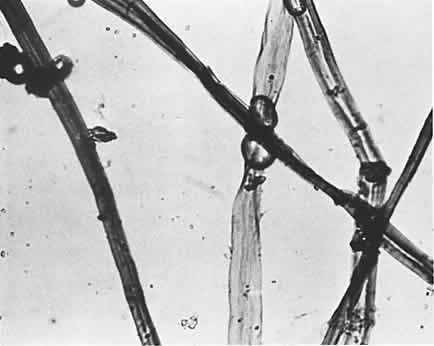

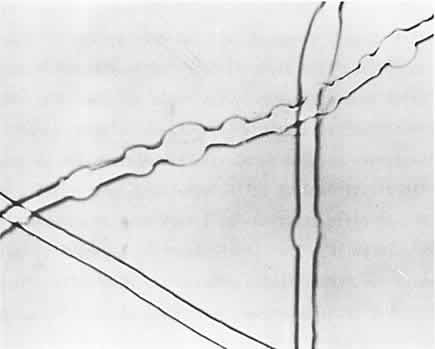

Another variable was found in the 100% kozo papers: associated lignified shive material. Of eighty-four papers tested, fifty-five papers (65.5%) were 100% bast fiber, and forty of the bast papers (72.7%) were 100% kozo. During analysis, it was noted that kozo fibers were often accompanied by associated lignified debris. The photomicrograph in Figure 1 illustrates a 100% kozo paper with very little residual shive material, whereas the 100% kozo paper seen in Figure 2 has a large amount of lignified debris still present. This lignified shive material occurs naturally in vascular plants, and is found under the bark in kozo plants. The fibers are surrounded by it. The lack of lignified material and debris in a kozo paper is an indication of the efficiency of both the beating and cooking processes. It is reasonable to assume the occurrence of residual lignified debris will effect the permanence of a paper.

Fig. 1

Fig. 2

Fourteen (25.5%) of the bast fiber paper group were of gampi or mitsumata. Under the microscope, it is quite difficult to differentiate between gampi and mitsumata fibers, even with stain. A simple test using sodium hydroxide was done to differentiate between the two types of fibers in every case. The results of a positive test for mitsumata can be seen in Figure 3.6 In no case did there appear to be a paper containing a combination of gampi and mitsumata. Also, in only one case, a paper called Kitakata Buff distributed through Light Impressions, was there found any additions of wood fibers to gampi or mitsumata, and then only 5% treated softwood was found.

Of all papers studied, only one paper consisted of 100% mixed bast fibers. Uda Thin, distributed by Andrews/Nelson/Whitehead, was found to contain 95% kozo and 5% of what appeared to be ramie, with an occasional contamination of a gampi fiber.

Two of the eighty-four papers were 100% leaf fibers. These two papers were L-Tissues made from manila hemp and distributed through Andrews/Nelson/Whitehead and University Products.

Some interesting fibers were found in three of the machine-made papers from Paper Nao. The papers were found to be about 75% bast with 25% grass. The grass fibers were, however, very unusual, as seen in the photomicrograph in Figure 4. Most straw and grass fibers are accompanied by a wide array of cellular debris, and the grass fibers found in the papers from Paper Nao were no exception. There were, however, quite unusual paraphernalia, such as several star-shaped cells and epidural cells with a very characteristic cupped shape. Many of the fibers occurred in bundles resembling ears of corn or sea anemone. At first, because of the wide variety of fiber widths, combinations of different kinds of fibers were considered. Some of the fibers were so thin the only possibility appeared to be pineapple, a leaf fiber. From the associated cellular matter, though, it was evident that grass or straw fibers were present. Some of the associated debris was similar to that found in bamboo, considered a grass, and since there are hundreds of species of bamboo plants, it was felt the unusual cellular matter might be from some obscure species of that genus. It was finally decided that the fibers should simply be labeled as grass fibers, and that the Paper Nao representative should be contacted for further information. The Paper Nao representative identified the "mystery fibers" as a form of Chinese miscanthus grass called ryususo.

Fig. 3

Fig. 4

Today, because of the high cost of Japanese bast fiber, many papermakers have added wood fiber to their stock. Of the eighty-four papers tested, twenty-three papers (27.4%) had wood fiber added. Nineteen of those twenty-three papers (82.6%) contained treated soft- and/or hardwoods. One particular type of softwood found was Douglas fir with its very characteristic striated spiral morphology. It is important to differentiate between Douglas fir and other softwood fibers because it has a higher weighting factor than most fibers.7

Some of the papers tested were found to contain small amounts of untreated processed wood fibers. Of the twenty-three papers found to contain wood fibers, four (17.4%) contained anywhere from 5-30% untreated softwood fibers.

It is interesting to note that there were three samples of Mulberry Paper tested, with varying fiber furnish. This is curious since one importer/distributor, Andrews/Nelson/Whitehead, sells to the other two distributors. It seems logical those three distributors would be selling the same paper. Yet the sample sent by one company tested out to have 20% untreated softwood. Another company sent a sample that proved to include 30% untreated softwood. These papers are similar. In fact, given the potential of +/- 5% margin of error in tabulation, they could be identical papers. The surprise is the fiber composition of the third paper, distributed by Andrews/Nelson/Whitehead, which appears to be made of 75% kozo and 25% softwood, with no untreated softwood.

There are a few inconsistencies of this sort, but none quite so extreme. It seems likely one is dealing with inconsistencies in the product from a particular supplier or a change to another supplier.

Summary and Conclusion

The Japanese papers examined in this study were found to be generally of good quality, based on fiber composition and initial pH readings. Fiber furnish is usually high-quality in traditional Japanese papermaking, since papermakers in that country are using primarily bast fibers. There are two factors, however, which do effect the quality of these papers: residual lignified shive material from partial processing and the addition of wood fiber as an extender. The amount of additional wood fiber, as well as whether it is treated, is easily quantified. Additions of wood fiber, even if treated, will surely effect the durability of a paper, and if untreated wood fiber is added, both permanence and durability are effected. More difficult to determine is the amount of the residual lignified product and the implications of its presence. Nevertheless, it seems clear that there is an inconsistency in the production of some of the papers which accounts for the unevenness in quality. For this reason, it is important to perform continued reviews of the quality of these papers. It will also be of interest to research the implications of these variables through artificial aging, followed by mechanical endurance tests. Quality checks such as this may raise the consciousness of the conservation community, in turn pressuring suppliers to produce products of unvarying high quality. Continued monitoring of these papers will help simplify the choice of products in the increasingly confusing market of conservation supplies.

Table 1. Japanese Papers Ranked By Fiber Quality

This ranking of papers by fiber content is based on the understanding that Japanese paper making fibers are the ideal papermaking fibers for this application and that non-traditional fibers or partially processed fibers are less desirable as components in the finished paper product.

| Group Ranking Criteria | |

| First (highest): fiber content | Papers with 100%bast kozo |

| Second: or gampi | Papers with 100% bast mitsumata |

| Third: | Papers with bast and leaf/grass fiber mixtures |

| Fourth: | Papers with bast and treated woody fibers |

| Fifth: | Papers with bast and untreated woody fibers |

| Key to Abbreviations | |

| AIKO | Aiko's Art Materials |

| ANW | Andrews/Nelson/Whitehead |

| LI | Light Impressions |

| PN | Paper Nao |

| UP | University Products |

| HW | hardwood |

| M/G | mitsumata/gampi |

| OB | other bast |

| SW | softwood |

| Paper | Supplier | DH |

| First (highest ranking) Group: 100% kozo | ||

| Hosokawa Ohban | ANW | 7.5 |

| K-13 | PN | 6.8 |

| K-30 | PN | 6.8 |

| K-31 | PN | 8.1 |

| K-33 | PN | 8.3 |

| K-35 | PN | 8.6 |

| K-43 | PN | 7.8 |

| K-45 | PN | 6.9 |

| K-60 | PN | 6.9 |

| K-62 | PN | 8.8 |

| K-63 | PN | 8.5 |

| K-64 | PN | 8.8 |

| K-65 | PN | 8.9 |

| Kaji Natural | ANW | 7.1 |

| Kitakata | ANW | 8.2 |

| Kizukishi | ANW | 7.3 |

| Kurotani Light (219) | AIKO | 8.5 |

| RK-2 | PN | 7.3 |

| RK-4 | PN | 8.7 |

| RK-5 | PN | 8.9 |

| RK-7 | PN | 8.9 |

| RK-9 | PN | 9.0 |

| RK-10 | PN | 8.2 |

| RK-12 | PN | 8.4 |

| RK-14 | PN | 7.7 |

| RK-20 | PN | 7.2 |

| RK-29 | PN | 7.3 |

| Sekishu Kozogami Mare | ANW | 7.9 |

| Sekishu Kozogami Turu | ANW | 8.2 |

| Sekishu Kozogami Turu (2238) | LI | 7.9 |

| Sekishu Torinoko Kozogami | UP | 7.7 |

| T-3 Tengujo (90) | AIKO | 7.4 |

| T-4 Yoshino (88) | AIKO | 7.3 |

| Tosa Tengujo | ANW | 7.1 |

| Uda Heavy (28) | AIKO | 9.5 |

| Uda Light (27) | AIKO | 8.7 |

| Uda Thin | UP | 9.4 |

| Uda Thin (2240) | LI | 9.5 |

| Udagami (2239) | LI | 8.5 |

| Udagami | UP | 8.8 |

| Udagami | ANW | 8.7 |

| Usumino (221-L) | AIKO | 6.3 |

| Second Group: 100% mitsumata or gampi | ||

| G-1 | PN | 7.0 |

| G-2 | PN | 6.8 |

| G-3 | PN | 7.5 |

| G-7 | PN | 7.1 |

| Gampi Dark Tissue (81) | AIKO | 6.7 |

| Gampi Medium Tissue (82) | AIKO | 6.9 |

| M-5 | PN | 6.6 |

| M-13 | PN | 8.1 |

| M-17 | PN | 8.0 |

| M-20 | PN | 7.6 |

| RG-1 | PN | 7.0 |

| Sekishu Torinoko Gampi | ANW | 6.8 |

| Sekishu Torinoko Gampi | UP | 6.9 |

| Silk Tissue | ANW | 8.6 |

| Third Group: bast or leaf/grass fibers | ||

| Thin Uda 100% mixed bast | ANW | |

| L-Tissue 100% leaf | ANW | 7.2 |

| L-Tissue 100% leaf | UP | 7.1 |

| RK-15 85% kozo and 15% grass | PN | 7.2 |

| RK-17 80% kozo and 20% grass | PN | 7.2 |

| RK-19 80% kozo and 20% grass | PN | 7.2 |

| Fourth Group: bast with treated woody fibers | ||

| K-51 95% kozo and 5% SW | PN | 7.2 |

| Kitakata Buff 95% M/G 5% SW | LI | |

| Kizukishi 95% kozo, 5% SW | UP | 7.0 |

| Kozo T-5 (20) 95% kozo, 5% SW | AIKO | 7.5 |

| Usumino (221-A) 95% kozo, 5% SW | AIKO | 7.4 |

| Oka (24) 90% kozo, 10% SW | AIKO | |

| Okawara 90% kozo, 5% OB, 5% SW | ANW | 6.8 |

| Tengujo (821) 90% kozo, 10% SW | AIKO | 7.9 |

| Kitakata 85% kozo, 5% OB, 10% SW | ANW | 8.2 |

| Gasenshi (T-11) 80% kozo, 15% M/G, 5% SW | AIKO | 7.5 |

| Sekishu Natural 80% kozo, 20% SW | ANW | 7.7 |

| Mulberry 75% kozo, 25% SW | ANW | 7.3 |

| Kizukishi (2237) 70% kozo, 30% SW | LI | 7.1 |

| Atsumino 60% kozo, 20% SW, 20% HW | AIKO | 5.0 |

| Sekishu White 50% kozo, 35% SW, 15% HW | ANW | 7.4 |

| Goyu White 45% kozo, 5% OB, 50% SW | LI | 7.1 |

| Sekishu White 45% kozo, 5% OB, 50% SW | LI | 7.1 |

| Sekishu Natural (2979) 40% kozo, 60% SW | LI | |

| Suzu (23) 40% kozo, 60% SW | AIKO | |

| Fifth Group: bast with untreated woody fibers | ||

| New Okawawa 90% kozo, 5% treated SW, 5% untreated SW | ANW | |

| Okawara (2229) 80% kozo, 10% treated SW10% untreated SW | LI | 7.1 |

| Mulberry Paper 40% kozo, 30% treated SW 30% untreated SW | UP | 6.8 |

| Mulberry Paper (2214) 30% kozo, 10% OB, 40% treated SW, 20% untreated SW | LI | 6.7 |

Table 2. Japanese Papers Ranked By Cold Extraction Ph

| Key to Abbreviations | |

| AIKO | Aiko's Art Materials |

| ANW | Andrews/Nelson/Whitehead |

| LI | Light Impressions |

| PN | Paper Nao |

| UP | University Products |

| N/A | Not Available |

| pH | Paper | Fiber Ouality Rank | Supplier |

| 9.5 | Usumino | First Group | AIKO |

| Uda Thin | First Group | LI | |

| 9.4 | Uda Thin | First Group | UP |

| 9.0 | RK-9 | First Group | PN |

| 8.9 | RK-7 | First Group | PN |

| RK-5 | First Group | PN | |

| K-65 | First Group | PN | |

| 8.8 | Udagami | First Group | UP |

| K-64 | First Group | PN | |

| K-62 | First Group | PN | |

| 8.7 | Uda Light | First Group | AIKO |

| Udagami | First Group | ANW | |

| RK-4 | First Group | PN | |

| 8.6 | Silk Tissue | Second Group | ANW |

| K-35 | First Group | PN | |

| 8.5 | Kurotani Light | First Group | AIKO |

| Udagami | First Group | LI | |

| K-63 | First Group | PN | |

| 8.4 | RK-12 | First Group | PN |

| 8.3 | K-33 | First Group | PN |

| 8.2 | RK-10 | First Group | PN |

| Kitakata | First Group | ANW | |

| Sekishu Kozogami Turu | First Group | ANW | |

| 8.1 | K-31 | First Group | PN |

| M-13 | Second Group | PN | |

| 8.0 | M-17 | Second Group | PN |

| 7.9 | Tengujo | Fourth Group | AIKO |

| Sekishu Kozogami Mare | First Group | ANW | |

| Sekishu Kozogami Turu | First Group | LI | |

| 7.8 | K-43 | First Group | PN |

| 7.7 | Sekishu Natural | Fourth Group | ANW |

| RK-14 | First Group | PN | |

| Sekishu Toronoko Kozo- gami | First Group | UP | |

| 7.6 | Hosokawa Ohban | First Group | ANW |

| M-20 | Second Group | PN | |

| 7.5 | Gasenshi | Fourth Group | AIKO |

| Kozo T-5 | Fourth Group | AIKO | |

| G-3 | Second Group | PN | |

| 7.4 | T-3 Tengujo | First Group | AIKO |

| Usumino | First Group | AIKO | |

| Sekishu White | Fourth Group | ANW | |

| RK-29 | First Group | PN | |

| 7.3 | T-4 Yoshino | First Group | AIKO |

| Kizukishi | First Group | ANW | |

| Mulberry | Fourth Group | ANW | |

| RK-2 | First Group | PN | |

| RK-29 | First Group | PN | |

| 7.2 | L-Tissue | Third Group | ANW |

| K-51 | Fourth Group | PN | |

| RK-15 | Third Group | PN | |

| RK-17 | Third Group | PN | |

| RK-19 | Third Group | PN | |

| RK-20 | First Group | ||

| 7.1 | Kaji Natural | First Group | ANW |

| Tosa Tengujo | First Group | ANW | |

| Goyu White | Fourth Group | LI | |

| Kizukishi | Fourth Group | LI | |

| Okawara | Fifth Group | LI | |

| Sekishu White | Fourth Group | LI | |

| G-7 | Second Group | PN | |

| L-Tissue | Third Group | UP | |

| 7.0 | G-1 | Second Group | PN |

| RG-1 | Second Group | PN | |

| Kizukishi | Fourth Group | UP | |

| 6.9 | Sekishu Torinoko Gampi | Second Group | UP |

| Gampi Medium Tissue | Second Group | AIKO | |

| K-45 | First Group | PN | |

| K-60 | First Group | PN | |

| 6.8 | Mulberry Paper | Fifth Group | UP |

| K-13 | First Group | PN | |

| Sekishu Torinoko Gampi | Second Group | ANW | |

| G-2 | Second Group | PN | |

| K-30 | First Group | PN | |

| Okawara | Fourth Group | ANW | |

| 6.7 | Gampi Dark Tissue | Second Group | AIKO |

| Mulberry Paper | Fifth Group | LI | |

| 6.6 | M-5 | Second Group | PN |

| 6.3 | Usumino | Fourth Group | AIKO |

| 5.0 | Atsumino | Fourth Group | AIKO |

| N/A | Oka | AIKO | |

| Suzu | ANW | ||

| New Okawara | ANW | ||

| Thin Uda | ANW | ||

| Kitakata Buff | LI | ||

| Sekishu Natural | LI | ||

Notes

1. noted by Browning, "The choice of extraction procedure depends on expected interpretation of the pH values found" (B. L. Browning, Analysis of Paper, [Appleton, Wisconsin: The Institute of Paper Chemistry, 19771, 170-1). According to Barrow, "When the rate of aging is judged by the rate of decrease in folding endurance, the cold extraction method gives higher pH values if the pH is below 7 ... [otherwise] the hot and cold extraction methods may be expected to give about the same values" (W. J. Barrow, "Hot vs. Cold Extraction Methods for Making a pH Determination," TAPPI, vol. 46, no. 8 [August 1963]: 468). Further tests on the Japanese papers may include fold endurance testing. Since cold water extraction is generally accepted in paper conservation for product testing, it seemed logical for the purposes of this study, therefore, to rely on cold water extraction as the means for obtaining the most accurate pH readings.

4. Processing refers simply to the cooking and beating part of the pulping process. It can infer chemical as well as mechanical preparation. According to McGovern, "Chemical pulping has as its purpose the selective removal of the fiber-bonding lignin to a varying degree with a minimum solution of the hemicelluloses and the celluloses" (J. N. McGovern, "Introduction to Pulping," Pulp and Paper: Chemistry and Chemical Technology, ed. by James P. Casey [New York: John Wiley & Sons, 1980), 1:161). Further purification can be continued in a bleaching step. For the purposes of this study, "treated" refers specifically to chemical treatment using bleach to remove the remaining lignin and lignified products both within the fibers and in the surrounding associated material. Therefore, to assure permanence, whenever wood products are used in paper fabrication, it is necessary to treat those fibers.

5. As explained by Barrett, the four major processes use calcium hydroxide (lime mortar), sodium hydroxide (caustic soda), sodium carbonate (soda ash), and wood ash (Timothy Barrett, Japanese Papermaking [New York: Weatherhill, 19831, 145-9). The use of calcium hydroxide is sometimes desirable as it can alkalinize the sheet to some degree. An information list sent out from Paper Nao included the cooking process used for each paper.

6.When a stained slide appeared to have either gampi or mitsumata fibers, a second chemical test was conducted on another slide using a drop of a 17.5% solution of sodium hydroxide. When the clear alkaline solution is added to gampi fibers, there is no response. However, when the solution is added to mitsumata, intermittent bulging and swelling occurs.

7. Most softwood fibers have a weight factor of 0.90. Douglas fir has a weight factor of 1.50. TAPPI method T-401 om-82 discusses the precision required in selection of proper weight factors. First demonstrated by Spence and Krauss (G. K. Spence and J. M. Krauss, Paper, vol. 20, no. 11 [May 19171:11-13), weighting factors were perfected by several researchers, especially J. H. Graff whose publications have been noted by Isenberg (I. H. Isenberg, Pulp and Paper Microscopy [Appleton, Wisconsin: The Institute of Paper Chemistry, 19671). The table of weighting factors used in this study is taken from Isenberg.