Speed of Deformation Effects Behavior

|

|

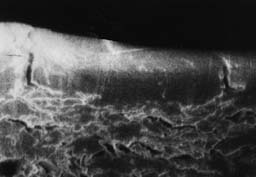

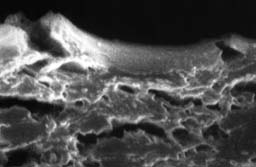

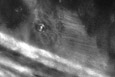

The following experiment was done to show that there is a time dependency for the cracking (failure) behavior. Faster strain rates results in brittle behavior while slow intrusion results in plastic behavior. The experiment was to push a needle probe into the surface of a chip of modern albumen made using the Towler method. The first part was done, fast, as one would normally

|

|

probe a material to see how hard or soft it might be. The slow part was done over about 2 minutes. The result of the slow experiment could only be seen when the probe was removed, revealing a depression; as can be seen in the image on the far right. This parallels results found in Vitale & Messier (1994), where the ultrasonic modulus (made at very high rates of strain) is high in comparison to those made in using the slow "equilibrium stress-strainng" protocol used in all

|

|

the remaining mechanical measurements. This highly interesting and revealing experiment was suggested by Duane Chartier (Culver City, CA).

|

|

|

|

|

|

|

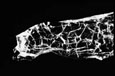

Chip before experiment

|

Start of fast intrusion

|

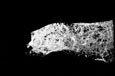

Result of fast intrusion

|

Start of slow intrusion

|

Result of slow intrusion, magnified

|

Why Albumen Behaves this Way

|

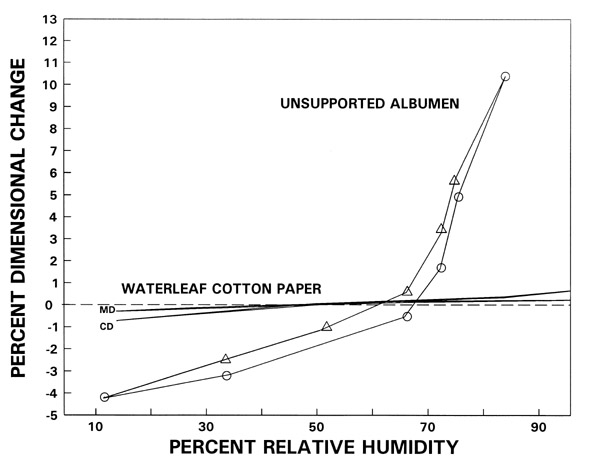

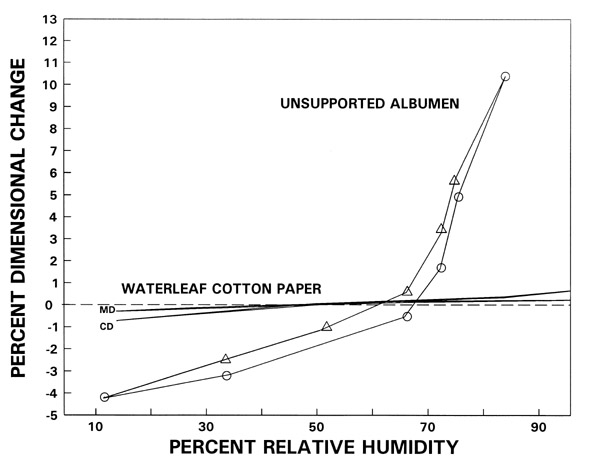

| Humidity: Albumen swells and shrinks to a greater degree than many materials. What makes this unfortunate property problematic is that swelling caused by to a 20% change in humidity (around 50% RH) is enough to cause already cracked albumen to increase crack sizes and possible to form new cracks. For modern albumen which is crack free, a 35% change in humidity (around 50% RH) will cause the creation of new cracks.

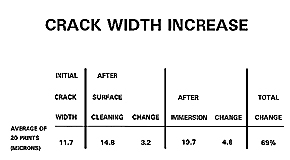

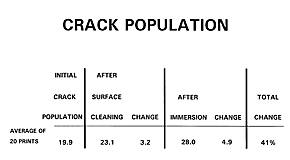

Wetting: If an albumen layer is swelled in water (immersion, for example), it swells so much (17+%) that a massive number for new cracks form and existing cracks increase in width; see above and Messier & Vitale (1994).

|

|

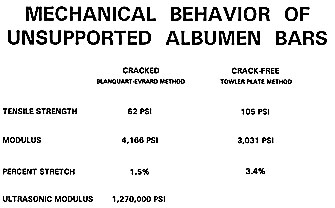

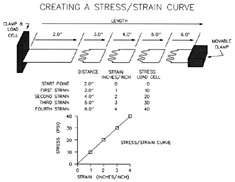

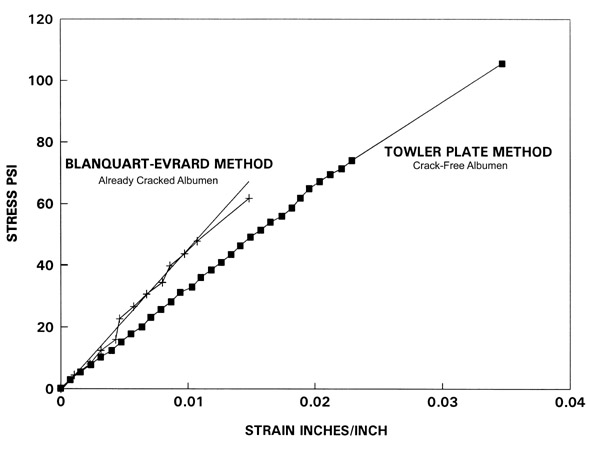

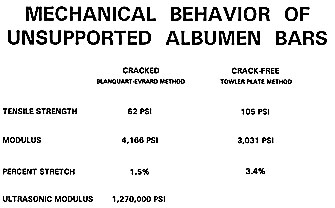

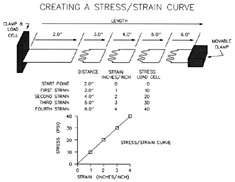

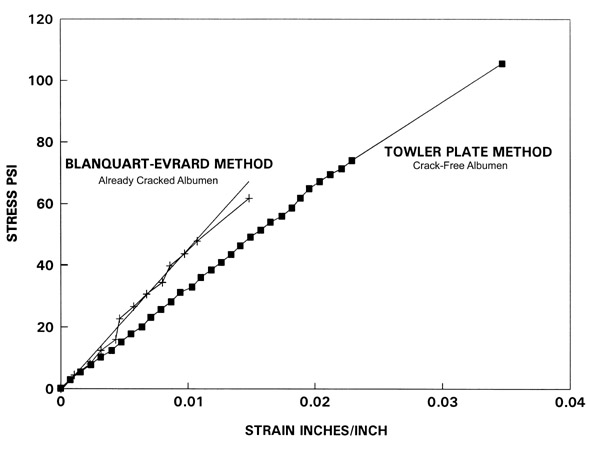

| This behavior is explained by the following two images. The plot above shows the dimensional of an albumen bar change due to swelling in air with increasing, and then decreasing, amounts of water vapor. Between 50% RH and 85% RH albumen swells 12.4%, and shrinks 11.8%. Note that the slight difference between swelling and deswelling is know as hystersis. In the second plot below, the result of a very slow straining process, shows that already cracked albumen (E-B Method) can only be strained 1.5% before it fails. Another sample of modern albumen made using a method which produced an albumen bar which was crack-free (Towler Plate Method) can be strained 3.4% before it fails. |

|

|

WHY?

Taking this data into consideration, the following chart shows the problem. If albumen goes from 50% RH to 20% RH, a strain of 1.7% will results from the humidity change. Our sample of cracked albumen failed when stretched (strained) 1.5%. Thus, cracks grow and "possibly" new ones form from a strain of 1.5% or greater. Note that the strain (inches per inch) is converted to percent by multiplying by 100; a strain of 0.01 is 1% strain (0.01 X 100) of the material.

|

|

Work was done at CAL, Smithsonian Institution

Conservation research was done at the Conservation Analytical Laboratory (CAL, now called SCMRE, Smithsonian Center for Materials Research and Education) by the authors between 1990-92. The goal was the personal need for understanding and to provide information to conservators, curators and collections managers so they could balance the obvious benefits of (1) aqueous treatment and (2) humidity changes with their drawbacks.

|

|